Simulating the effect of vibration and shock on closure integrity

Simulating the Effect of Vibration and Shock on Closure Integrity A Crucial Laboratory Service for Ensuring Product Reliability

In todays fast-paced business landscape, ensuring the reliability and integrity of products is crucial for companies operating in various industries. One critical factor that can significantly impact product performance is the effect of vibration and shock on closure integrity. As a leading laboratory service provider, Eurolab offers a specialized testing solution to simulate the effects of vibration and shock on closure integrity, empowering businesses to make informed decisions about their products design, development, and quality control.

What is Simulating the Effect of Vibration and Shock on Closure Integrity?

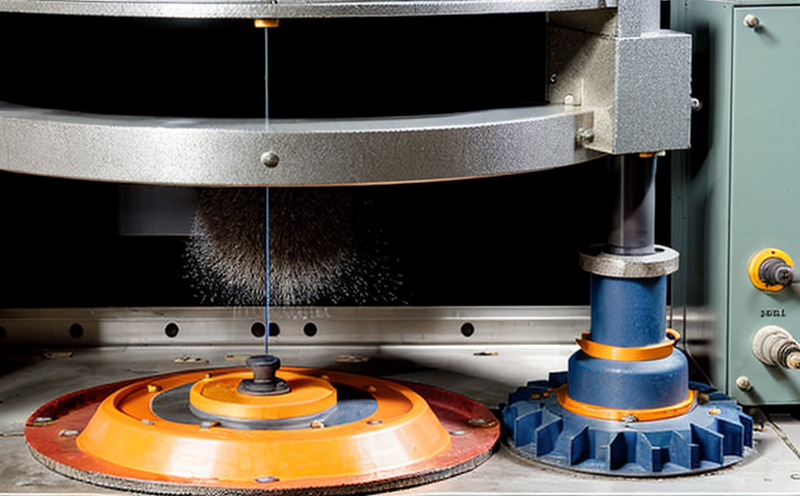

Simulating the effect of vibration and shock on closure integrity involves subjecting a products closure system to various levels of vibration and shock forces to evaluate its ability to maintain seal integrity under extreme conditions. This laboratory service utilizes sophisticated testing equipment to replicate real-world scenarios, such as transportation, storage, or usage environments, where products may be exposed to vibrations and shocks.

Why is Simulating the Effect of Vibration and Shock on Closure Integrity Essential for Businesses?

The importance of simulating vibration and shock effects on closure integrity cannot be overstated. Here are some compelling reasons why businesses should consider this laboratory service

Ensures Product Reliability By testing a products closure system under extreme conditions, Eurolab helps companies identify potential weaknesses and vulnerabilities that could compromise product performance.

Reduces Warranty Claims and Liability Products that have undergone rigorous testing for vibration and shock effects are less likely to fail in the field, thereby reducing warranty claims and liability risks for businesses.

Compliance with Industry Standards Many industries, such as aerospace, automotive, and pharmaceuticals, require products to meet specific standards for vibration and shock resistance. Eurolabs laboratory service ensures compliance with these regulations.

Improves Product Design and Development By identifying areas of improvement, Eurolabs testing services enable companies to refine their product designs and development processes, resulting in more reliable and efficient products.

Advantages of Using Simulating the Effect of Vibration and Shock on Closure Integrity

Here are some key benefits of using Eurolabs laboratory service for simulating vibration and shock effects

Accurate Results Our state-of-the-art testing equipment provides precise and reliable results, giving you confidence in your products performance.

Customized Testing Solutions We offer tailored testing programs to meet the specific needs of your products, taking into account various factors such as size, material, and intended use.

Timely Turnaround Our experienced team ensures that testing is completed efficiently, minimizing downtime and allowing you to bring products to market faster.

Compliance with International Standards Eurolabs laboratory service adheres to international standards for vibration and shock testing, ensuring your products meet global requirements.

Frequently Asked Questions (FAQs)

Here are some answers to common questions about simulating the effect of vibration and shock on closure integrity

What types of products can be tested using this laboratory service?

A wide range of products, including containers, packages, closures, and valves.

How do I prepare my product for testing?

Provide your product in its final form, ensuring it is representative of the intended use condition.

Can Eurolab provide customized testing programs for our specific needs?

Yes, we offer tailored testing solutions to meet your unique requirements.

What are the turnaround times for testing and reporting results?

We strive to complete testing within 2-5 business days, depending on the scope of work.

Conclusion

In conclusion, simulating the effect of vibration and shock on closure integrity is a critical laboratory service that empowers businesses to ensure their products reliability and compliance with industry standards. By partnering with Eurolab, companies can

Ensure product reliability and reduce warranty claims

Comply with international standards for vibration and shock testing

Improve product design and development through data-driven insights

Dont risk compromising your products performance or reputation; trust Eurolab to provide accurate and reliable results. Contact us today to learn more about our laboratory services and how we can help you achieve excellence in product reliability.