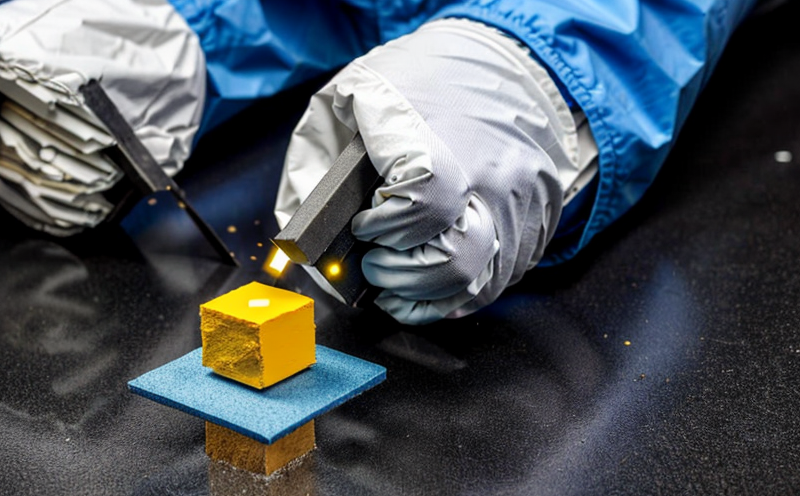

Testing the physical properties of closure materials under stress

Testing the Physical Properties of Closure Materials Under Stress Unlocking Reliability and Safety for Your Business

In todays fast-paced world, packaging plays a vital role in protecting products during transportation, storage, and distribution. One critical aspect of packaging is the closure material, which ensures that products remain secure and tamper-evident throughout their lifecycle. However, closures are subjected to various stresses, such as pressure, temperature fluctuations, and physical impact, which can compromise their integrity.

At Eurolab, we understand the significance of testing the physical properties of closure materials under stress. This laboratory service provides businesses with a comprehensive evaluation of their closure materials performance in real-world conditions, ensuring reliability, safety, and compliance with regulatory requirements. In this article, we will delve into the importance of Testing the physical properties of closure materials under stress, its benefits, and how Eurolabs expert services can help your business thrive.

The Importance of Testing Closure Materials Under Stress

Closure materials are often made from a combination of plastics, metals, and other materials, which may undergo degradation or failure when exposed to various stresses. This can lead to costly product recalls, damage to brand reputation, and even harm to consumers. Regular testing of closure materials under stress enables businesses to

Ensure compliance with regulatory requirements Many industries have strict regulations regarding packaging safety and performance. Testing closure materials under stress helps businesses demonstrate their commitment to quality and compliance.

Reduce the risk of product failure By evaluating the robustness of closure materials, companies can minimize the likelihood of products being compromised during transportation or storage.

Enhance product reliability Regular testing ensures that closure materials continue to perform optimally over time, even in extreme conditions.

Advantages of Testing the Physical Properties of Closure Materials Under Stress

Our laboratory service at Eurolab offers numerous benefits for businesses seeking to optimize their packaging performance. Some key advantages include

Cost savings through reduced product failures By identifying potential weaknesses in closure materials, companies can avoid costly product recalls and minimize financial losses.

Improved supply chain efficiency Testing closure materials under stress helps businesses streamline logistics by reducing the risk of products being compromised during transportation.

Enhanced brand reputation Demonstrating a commitment to quality and safety through regular testing can boost customer confidence and loyalty.

Compliance with industry standards Our expert services ensure that your business meets or exceeds regulatory requirements, minimizing the risk of non-compliance fines and penalties.

Key Benefits for Various Industries

Testing the physical properties of closure materials under stress has far-reaching implications across various industries. Some key benefits include

Pharmaceuticals and Healthcare Ensure tamper-evident packaging maintains its integrity throughout storage and transportation.

Food and Beverage Verify that closure materials withstand extreme temperatures, moisture levels, and other environmental stresses.

Cosmetics and Personal Care Evaluate the performance of closure materials under various pressures to ensure product safety and efficacy.

Industrial and Chemicals Assess the durability of closure materials in harsh environments and under extreme conditions.

QA Frequently Asked Questions

At Eurolab, were committed to providing transparent and reliable laboratory services. Here are some frequently asked questions regarding our Testing the physical properties of closure materials under stress service

Q What types of tests do you offer?

A Our comprehensive testing package includes a range of methods, including tensile strength testing, impact resistance testing, and environmental chamber testing.

Q How long does the testing process take?

A The duration of testing depends on the specific requirements of each project. Our team will work closely with your business to ensure timely delivery of results.

Q What kind of data do you provide after testing?

A Our expert analysts will deliver detailed reports, including visual documentation and statistical analysis, to help businesses interpret their test results.

Q Can I customize my testing package?

A Absolutely! Our team is committed to tailoring our services to meet the unique needs of your business. Well work closely with you to develop a customized testing plan.

Conclusion

In todays competitive market, businesses must prioritize product safety, reliability, and compliance to maintain a strong brand reputation. Testing the physical properties of closure materials under stress is an essential step in ensuring that products remain secure and tamper-evident throughout their lifecycle. At Eurolab, our expert team offers comprehensive laboratory services designed to meet the unique needs of your business.

By leveraging our Testing the physical properties of closure materials under stress service, you can

Enhance product reliability and safety

Reduce costs associated with product failures

Comply with regulatory requirements

Improve supply chain efficiency

Dont compromise on quality or risk compromising your business. Trust Eurolabs expert laboratory services to ensure the integrity and performance of your closure materials under stress. Contact us today to discuss how our Testing the physical properties of closure materials under stress service can support your business goals.