Unlocking the Secrets of Your Small Parts Why Eurolabs Small Part Evaluation Service is a Game-Changer for Businesses

In todays fast-paced and highly competitive business landscape, ensuring the quality and reliability of your products is crucial to maintaining customer trust and satisfaction. For companies that manufacture or distribute complex components, small parts evaluation is an essential laboratory service that can make all the difference between success and failure.

At Eurolab, our Small Part Evaluation service is designed to provide businesses with a comprehensive understanding of their small parts performance, safety, and reliability. By analyzing these critical components, we help companies identify potential issues before they become major problems, saving time, money, and resources in the long run.

In this article, well delve into the world of small part evaluation, exploring its benefits, advantages, and importance for businesses. Well also answer frequently asked questions about our service to give you a deeper understanding of what sets Eurolab apart from the competition.

What is Small Part Evaluation?

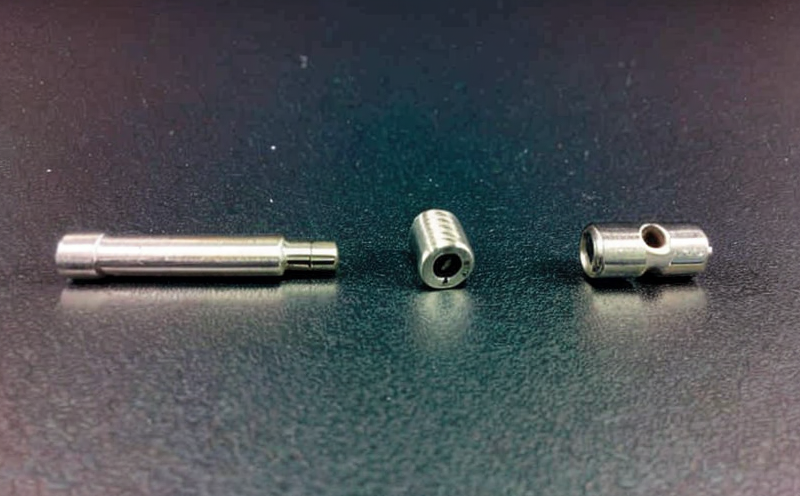

Small part evaluation involves conducting rigorous testing and analysis on intricate components that are crucial to the performance and functionality of larger products. These parts, often measuring mere millimeters or even micrometers in size, play a vital role in ensuring the overall quality and reliability of finished goods.

Our small part evaluation service includes a range of laboratory tests designed to assess various aspects of these tiny components, such as

Material properties (e.g., strength, conductivity)

Dimensional accuracy and precision

Surface finish and roughness

Chemical composition and contamination

Mechanical performance (e.g., fatigue, wear resistance)

Why is Small Part Evaluation Essential for Businesses?

In todays demanding market, businesses must prioritize quality control to maintain a competitive edge. Here are just some of the compelling reasons why small part evaluation is essential for companies

Reduced Product Returns and Liability By identifying potential issues early on, you can minimize product returns, customer complaints, and liability claims.

Improved Supply Chain Management Our service helps you verify the quality of incoming raw materials or components from suppliers, ensuring a smoother supply chain process.

Increased Efficiency and Reduced Costs Small part evaluation enables you to optimize your manufacturing processes by identifying areas for improvement and reducing waste.

Enhanced Product Performance and Reliability By understanding how small parts interact with other components, you can develop more reliable products that meet customer expectations.

Key Benefits of Eurolabs Small Part Evaluation Service

Here are the key benefits of choosing our Small Part Evaluation service

Customized Testing Solutions Our experienced team works closely with clients to design tailored testing programs that address specific concerns and requirements.

State-of-the-Art Laboratory Facilities We maintain modern, well-equipped laboratory facilities equipped with advanced instrumentation and technology to ensure accurate and reliable results.

Expert Analysis and Reporting Our skilled analysts provide detailed reports and recommendations for improving product quality, reducing costs, and minimizing risk.

Compliance with Industry Standards We help clients meet regulatory requirements by testing to relevant industry standards (e.g., ISO 14649, ASTM E1755).

Flexible Sampling Options Our flexible sampling policies enable you to send small quantities of parts for analysis without incurring excessive costs.

How Does Small Part Evaluation Work?

Our small part evaluation process typically involves the following steps

Sample Preparation and Submission Clients prepare samples according to our guidelines or provide us with existing samples.

Initial Assessment and Test Planning Our team reviews sample data, identifies potential testing requirements, and develops a customized test plan.

Testing and Analysis We conduct laboratory tests on the small parts, using advanced equipment and techniques as needed.

Reporting and Recommendations Analytical results are documented in comprehensive reports, providing actionable insights for process improvements.

Frequently Asked Questions (FAQs)

Here are answers to some of our most frequently asked questions about Small Part Evaluation

Q What types of small parts can be evaluated?

A We analyze a wide range of small parts, including components made from metals, plastics, ceramics, and composites.

Q Can I send in any type of sample for analysis?

A Yes! Our flexible sampling policies enable us to accept various sample formats (e.g., as-received, cleaned, or treated).

Q How long does the testing process take?

A The duration depends on the number of samples, testing requirements, and complexity of analyses. Typically, results are available within 2-4 weeks.

Q Can I get assistance with sampling and preparation?

A Absolutely! Our team can guide you through the sample preparation process to ensure your samples meet our submission guidelines.

Why Choose Eurolab for Small Part Evaluation?

At Eurolab, we pride ourselves on providing top-notch laboratory services that meet the highest standards of quality and reliability. Heres why businesses trust us with their small part evaluation needs

Unparalleled Expertise Our experienced team includes professionals with in-depth knowledge of materials science, mechanical engineering, and laboratory testing.

State-of-the-Art Facilities Our laboratories are equipped with advanced instrumentation and technology to ensure accurate results and minimize analysis time.

Personalized Service We offer customized testing solutions tailored to each clients specific needs and requirements.

By partnering with Eurolab for Small Part Evaluation, you can

Enhance product quality and reliability

Reduce costs and liabilities associated with defective products

Improve supply chain management and efficiency

Gain a competitive edge in the market

Dont let small part evaluation hold your business back. Contact us today to learn more about how Eurolabs Small Part Evaluation service can revolutionize your quality control processes!

-

Evaluating the safety of small parts in consumer products to prevent choking hazards for children

-

Testing for the potential risk of small parts becoming detached from products during use

-

Simulating conditions where small parts may become dislodged or separated from consumer goods

-

Assessing the size and design of small components in products to ensure they are safe for all users

-

Testing the durability of small parts under stress or wear conditions to prevent breakage or loss

-

Evaluating the attachment mechanisms of small parts, such as buttons, caps, or fasteners, to prevent detachment

-

Testing for compliance with safety standards related to small parts in children's toys, clothing, and household goods

-

Simulating real-world handling of products to assess if small parts pose risks of ingestion or injury

-

Verifying that small parts meet safety criteria for toys and products intended for infants and toddlers

-

Assessing the likelihood of small parts becoming loose or hazardous during transportation or shipping

-

Testing for the mechanical integrity of small parts to ensure they withstand regular use without breaking

-

Evaluating the design and placement of small parts to prevent potential safety issues in products

-

Simulating exposure to environmental factors like moisture, heat, or pressure to test small part durability

-

Testing for sharpness or pointed edges in small parts that could lead to injury

-

Assessing the potential for small parts to cause malfunction or failure in electronic devices or appliances

-

Testing for small parts that may become hazards in items like household tools, office supplies, and toys

-

Verifying the safety of products that include removable or detachable small parts

-

Ensuring that small parts are securely fastened and do not pose a risk of detachment during product life

-

Testing small parts in products designed for medical or personal care to ensure safety and reliability

-

Simulating accidental impacts to assess the potential for small parts to dislodge and cause harm

-

Evaluating the consumer education needed to mitigate risks from small parts in products intended for children