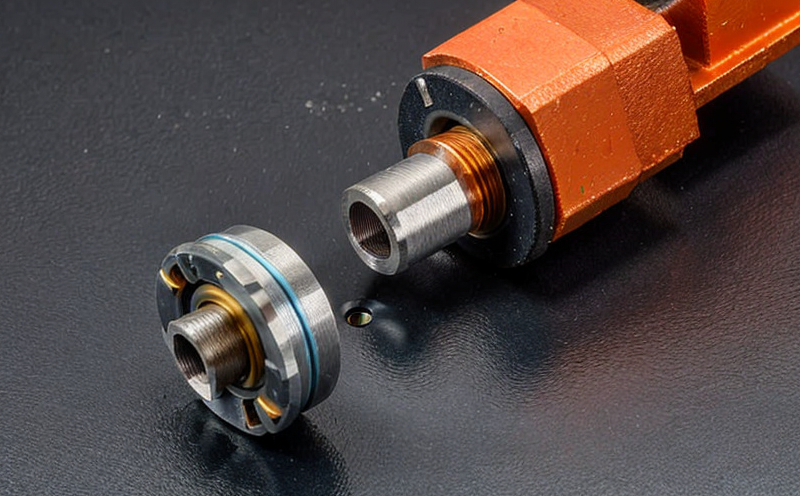

Testing the durability of small parts under stress or wear conditions to prevent breakage or loss

Title The Crucial Role of Testing Durability Preventing Breakage and Loss with Eurolabs Expert Services

Introduction

In todays fast-paced business world, the success of a company largely depends on its ability to innovate, adapt, and ensure product reliability. One critical aspect that often gets overlooked is testing the durability of small parts under stress or wear conditions. This seemingly minor aspect can have significant implications for businesses across various industries, from manufacturing to automotive. Breakage or loss of critical components can lead to costly production downtime, damage to reputation, and even safety hazards. Thats where Eurolab comes in a leading laboratory service provider specializing in testing the durability of small parts under stress or wear conditions.

Why Testing Durability Matters

The importance of testing durability cannot be overstated. With increasingly complex products and components, businesses face growing pressure to ensure their products can withstand various environmental factors, usage patterns, and operational conditions. Testing durability is not merely a preventive measure; its an essential investment in quality assurance, product design, and customer satisfaction.

Key Advantages of Testing Durability with Eurolab

At Eurolab, we recognize the importance of providing businesses with cutting-edge testing services that cater to their unique needs. Our laboratory offers a range of benefits when it comes to testing the durability of small parts under stress or wear conditions

Benefits for Product Design and Development

Improved product design By simulating real-world conditions in our lab, you can optimize your products performance and reliability.

Enhanced customer satisfaction Products that last longer reduce returns and enhance the overall user experience.

Reduced production costs Identifying potential issues early on saves time and resources.

Benefits for Quality Assurance

Compliance with industry standards Our tests ensure you meet regulatory requirements, protecting your business from reputational damage.

Minimized risk of product recalls By identifying defects or weaknesses before mass production, you can prevent costly recalls.

Increased confidence in product quality With Eurolabs expert testing services, you can be certain that your products meet the highest standards.

Benefits for Business Operations

Reduced downtime and loss Early detection of potential issues minimizes the risk of production stoppages.

Enhanced operational efficiency Our tests help you streamline processes by identifying areas for improvement.

Cost savings through predictive maintenance By understanding your products lifespan, you can plan maintenance more effectively.

Benefits for Research and Development

Accelerated innovation Our state-of-the-art facilities enable faster testing cycles, allowing you to bring new products to market sooner.

Data-driven decision-making With comprehensive test results, you can make informed decisions on product development.

Competitive edge through cutting-edge technology Collaborate with our team of experts to stay ahead in your field.

QA Section

Q What types of materials and components can be tested?

A Our laboratory services cater to a wide range of materials and components, including metals, plastics, ceramics, and composites. We also test various product types, such as mechanical parts, electrical components, and automotive systems.

Q How do I prepare my samples for testing?

A Simply provide us with your samples in the desired condition, along with any relevant documentation or specifications. Our team will handle all necessary preparation and testing procedures.

Q What types of tests can be performed at Eurolab?

A We offer a comprehensive range of tests to simulate various environmental conditions, including temperature, humidity, vibration, corrosion, and wear. Our state-of-the-art equipment enables us to conduct both static and dynamic tests.

Q How long does the testing process take?

A The duration of our tests varies depending on the specific requirements of your project. However, we strive to complete most projects within a few weeks or months, ensuring minimal disruption to your operations.

Q Can I customize my testing protocol?

A Absolutely! Our team works closely with you to create a tailored testing plan that meets your unique needs and goals. We understand the importance of precision in product development and will collaborate with you every step of the way.

Conclusion

In todays competitive business landscape, staying ahead requires a commitment to quality and reliability. By partnering with Eurolab for testing the durability of small parts under stress or wear conditions, you can ensure that your products meet the highest standards. Our team of experts is dedicated to providing cutting-edge laboratory services that cater to your specific needs, from product design and development to quality assurance and research. Dont let breakage or loss compromise your businesss success choose Eurolab for peace of mind in a world where precision matters.

-

Evaluating the safety of small parts in consumer products to prevent choking hazards for children

-

Testing for the potential risk of small parts becoming detached from products during use

-

Simulating conditions where small parts may become dislodged or separated from consumer goods

-

Assessing the size and design of small components in products to ensure they are safe for all users

-

Evaluating the attachment mechanisms of small parts, such as buttons, caps, or fasteners, to prevent detachment

-

Testing for compliance with safety standards related to small parts in children's toys, clothing, and household goods

-

Simulating real-world handling of products to assess if small parts pose risks of ingestion or injury

-

Verifying that small parts meet safety criteria for toys and products intended for infants and toddlers

-

Assessing the likelihood of small parts becoming loose or hazardous during transportation or shipping

-

Testing for the mechanical integrity of small parts to ensure they withstand regular use without breaking

-

Evaluating the design and placement of small parts to prevent potential safety issues in products

-

Simulating exposure to environmental factors like moisture, heat, or pressure to test small part durability

-

Testing for sharpness or pointed edges in small parts that could lead to injury

-

Assessing the potential for small parts to cause malfunction or failure in electronic devices or appliances

-

Testing for small parts that may become hazards in items like household tools, office supplies, and toys

-

Verifying the safety of products that include removable or detachable small parts

-

Ensuring that small parts are securely fastened and do not pose a risk of detachment during product life

-

Testing small parts in products designed for medical or personal care to ensure safety and reliability

-

Simulating accidental impacts to assess the potential for small parts to dislodge and cause harm

-

Evaluating the consumer education needed to mitigate risks from small parts in products intended for children