Stress Testing for Folding Mechanism Hinges and Joints

The Crucial Role of Stress Testing for Folding Mechanism Hinges and Joints in Ensuring Product Reliability

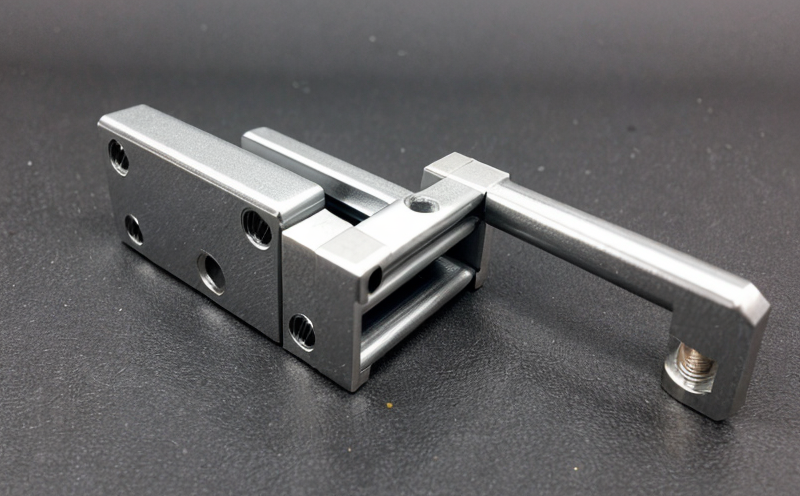

In todays fast-paced manufacturing environment, businesses are constantly seeking ways to optimize their products performance, efficiency, and durability. One critical aspect that often gets overlooked is the testing of folding mechanism hinges and joints. These components are the backbone of many everyday items, from furniture to machinery, but their reliability can be compromised by stress, wear, and tear.

This is where Stress Testing for Folding Mechanism Hinges and Joints comes into play a laboratory service offered by Eurolab that enables businesses to evaluate the strength and durability of these critical components. By investing in this testing process, companies can ensure their products meet the highest standards of quality, safety, and performance.

What is Stress Testing for Folding Mechanism Hinges and Joints?

Stress Testing for Folding Mechanism Hinges and Joints is a comprehensive laboratory service designed to assess the reliability and durability of these critical components. This testing process involves subjecting samples to various levels of stress, strain, and fatigue to evaluate their performance under real-world conditions.

Advantages of Stress Testing for Folding Mechanism Hinges and Joints

Eurolabs Stress Testing for Folding Mechanism Hinges and Joints offers numerous benefits for businesses looking to enhance product reliability. Here are the key advantages

Improved Product Reliability By identifying potential weaknesses in folding mechanism hinges and joints, businesses can design and manufacture more robust products that meet customer expectations.

Enhanced Safety Stress testing ensures that these critical components can withstand various loads and stresses without compromising safety features, reducing the risk of accidents and injuries.

Reduced Maintenance Costs By identifying wear-and-tear issues early on, maintenance costs are minimized, and downtime is reduced.

Increased Customer Satisfaction Products that meet or exceed customer expectations in terms of durability and performance lead to increased satisfaction, loyalty, and repeat business.

Compliance with Industry Standards Stress testing ensures compliance with industry standards and regulations, such as those set by the International Organization for Standardization (ISO).

Cost Savings through Design Optimization By identifying areas where design improvements can be made, businesses can optimize their products performance while reducing costs.

How Does Eurolabs Stress Testing Service Work?

Eurolabs expert team follows a rigorous testing process to evaluate the strength and durability of folding mechanism hinges and joints

Sampling and Preparation Samples are carefully selected, cleaned, and prepared for testing.

Testing Protocols Customized testing protocols are developed based on industry standards and customer requirements.

Stress Testing Samples are subjected to various levels of stress, strain, and fatigue using specialized equipment.

Data Analysis Test results are analyzed using advanced software and techniques to identify areas for improvement.

Key Benefits of Stress Testing

Here are the key benefits of Eurolabs Stress Testing service

Comprehensive Results Detailed test reports provide a thorough understanding of folding mechanism hinges and joints performance under stress.

Customized Solutions Expert analysis helps businesses develop targeted design improvements to enhance product reliability and performance.

Rapid Turnaround Times Eurolab offers expedited testing services to meet tight deadlines without compromising on quality.

QA Section

Q What types of products benefit from Stress Testing for Folding Mechanism Hinges and Joints?

A This service is beneficial for a wide range of products, including furniture, machinery, medical equipment, and more.

Q How does Eurolabs testing process ensure compliance with industry standards?

A Our expert team follows industry-recognized protocols and procedures to ensure that test results are accurate and compliant with relevant regulations.

Q Can Stress Testing for Folding Mechanism Hinges and Joints be performed on-site?

A No, Eurolabs laboratory is equipped with specialized equipment and trained personnel to perform this service. On-site testing is not feasible due to the need for controlled laboratory conditions.

Q What kind of data can businesses expect from Stress Testing reports?

A Test results include detailed analysis of folding mechanism hinges and joints performance under stress, including load capacity, fatigue life, and wear-and-tear issues.

Conclusion

In todays competitive manufacturing environment, investing in Stress Testing for Folding Mechanism Hinges and Joints is a crucial step towards ensuring product reliability and safety. By partnering with Eurolab, businesses can take advantage of our expert services to optimize their products performance while reducing costs and improving customer satisfaction. Dont compromise on the quality and durability of your products choose Eurolab for Stress Testing solutions that deliver real results.