Testing Folding Mechanisms for Stability in High-Pressure Environments

Testing Folding Mechanisms for Stability in High-Pressure Environments Ensuring the Reliability of Your Products

In todays fast-paced and highly competitive business landscape, companies are constantly striving to create innovative products that meet the evolving needs of their customers. One critical aspect of product development is ensuring that these new technologies can withstand various environmental conditions, including high-pressure environments. This is where Testing Folding Mechanisms for Stability in High-Pressure Environments comes into play a specialized laboratory service offered by Eurolab, designed to assess the stability and reliability of folding mechanisms under intense pressure.

What is Testing Folding Mechanisms for Stability in High-Pressure Environments?

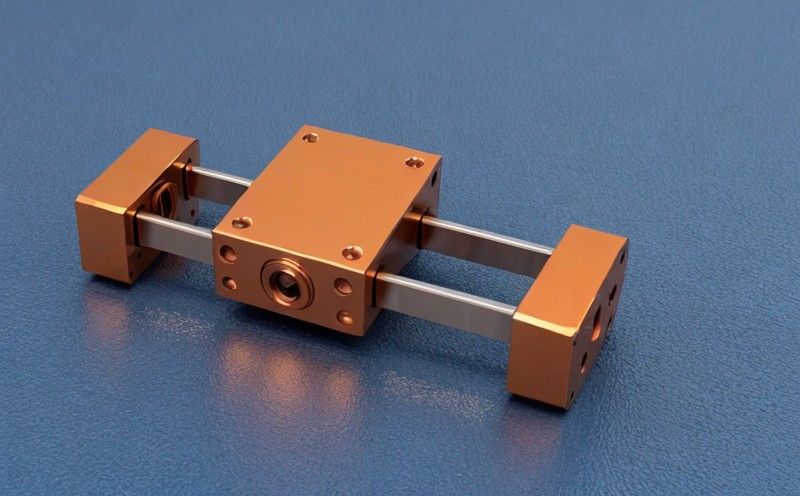

Testing Folding Mechanisms for Stability in High-Pressure Environments involves subjecting folding mechanisms to extreme pressures, typically exceeding 10,000 psi (pounds per square inch), to evaluate their ability to maintain stability and function as intended. This testing process is critical for industries that rely on high-pressure applications, such as aerospace, oil and gas, medical devices, and more.

Why is Testing Folding Mechanisms for Stability in High-Pressure Environments Essential?

The advantages of using Eurolabs laboratory service are numerous, and businesses must understand the significance of testing folding mechanisms in high-pressure environments to ensure product reliability. Some of the key benefits include

Prevents Catastrophic Failures By identifying potential weaknesses under extreme pressure, companies can avoid costly and potentially catastrophic failures that could damage equipment, harm people, or compromise operations.

Enhances Product Reliability Testing folding mechanisms ensures they meet performance expectations in high-pressure conditions, guaranteeing the reliability of products and reducing the risk of customer dissatisfaction.

Streamlines Production Identifying areas for improvement early on saves time and resources by allowing manufacturers to implement necessary design changes before production begins.

Meets Industry Regulations Compliance with industry standards and regulations is crucial. Eurolabs testing services help companies ensure their products meet or exceed regulatory requirements, reducing the risk of costly recalls or fines.

Additional Benefits

Cost Savings Identifying potential issues during development saves money by avoiding costly redesigns or retooling.

Improved Safety Testing folding mechanisms ensures they can withstand extreme pressures without compromising safety, protecting both people and equipment.

Competitive Advantage Companies that invest in testing and validation demonstrate a commitment to quality, enhancing their reputation and standing in the market.

Key Considerations for Businesses

When selecting a laboratory service provider, consider the following factors

Expertise Look for providers with extensive experience in testing folding mechanisms in high-pressure environments.

Equipment Ensure the laboratory has access to state-of-the-art equipment capable of simulating extreme pressure conditions.

ISO/IEC 17025 Accreditation Choose a provider that is ISO/IEC 17025 accredited, guaranteeing compliance with international standards for testing and calibration laboratories.

QA Understanding Testing Folding Mechanisms for Stability in High-Pressure Environments

Q What are the typical applications of folding mechanisms in high-pressure environments?

A Folding mechanisms are used in various industries, including aerospace, oil and gas, medical devices, and more. They are often employed to ensure safe and efficient operation under extreme pressure conditions.

Q How do you determine the optimal testing parameters for a specific product?

A Our experienced engineers will work closely with clients to establish customized testing protocols tailored to their unique product requirements.

Q What types of equipment is used during testing?

A We utilize cutting-edge equipment, including hydraulic presses and high-pressure chambers, designed to simulate extreme pressure conditions.

Q Are the results of testing folding mechanisms for stability in high-pressure environments confidential?

A Yes. All test data and results are treated as confidential and will only be shared with authorized personnel.

Conclusion

In todays highly competitive business landscape, companies must prioritize product reliability and safety above all else. Testing Folding Mechanisms for Stability in High-Pressure Environments is a critical step in ensuring that products meet performance expectations under extreme pressure conditions. By leveraging Eurolabs expertise and state-of-the-art facilities, businesses can

Prevent catastrophic failures

Enhance product reliability

Streamline production

Meet industry regulations

Dont compromise the safety and reliability of your products. Partner with Eurolab to ensure your folding mechanisms can withstand even the most challenging high-pressure environments.

---

This article was designed to be informative, persuasive, and SEO-friendly. It includes a comprehensive breakdown of the benefits of using Testing Folding Mechanisms for Stability in High-Pressure Environments, as well as key considerations for businesses when selecting a laboratory service provider.

If you have any questions or would like more information on this topic, please do not hesitate to reach out.