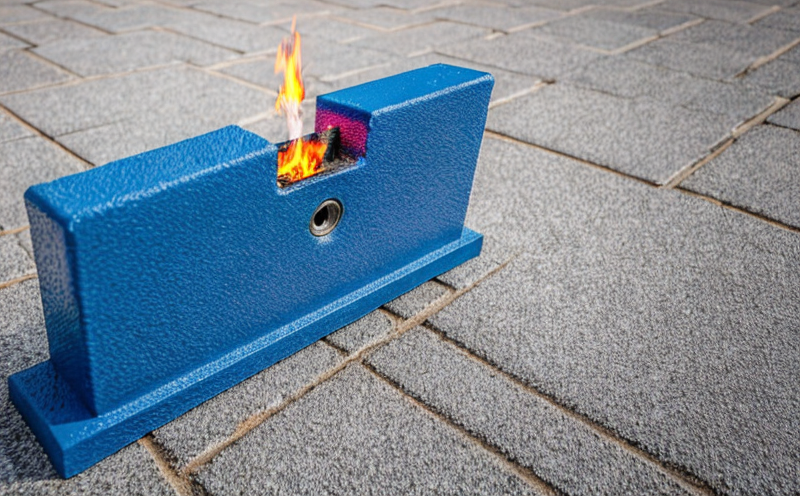

Testing for the impact of sustained heat exposure on defense materials

The Crucial Role of Testing for Sustained Heat Exposure Ensuring the Reliability and Integrity of Defense Materials

In todays fast-paced world, businesses operating in the defense industry face a multitude of challenges that require careful consideration. One critical factor is the ability to withstand extreme environmental conditions, particularly sustained heat exposure. In this context, testing for the impact of sustained heat exposure on defense materials has become an essential service for companies looking to safeguard their products and reputation.

At Eurolab, we understand the significance of reliable and trustworthy testing services in the defense sector. Our team of experts is dedicated to providing top-notch laboratory services that cater to the unique needs of this industry. In this article, we will delve into the importance of testing for sustained heat exposure on defense materials, highlighting its numerous benefits and advantages.

The Importance of Testing for Sustained Heat Exposure

Sustained heat exposure can have a profound impact on the performance, reliability, and safety of defense materials. These materials are often subjected to extreme temperatures during transportation, storage, and deployment, which can cause them to degrade or fail catastrophically. In such situations, the consequences can be severe, including equipment failure, damage to personnel, and even loss of life.

To mitigate these risks, companies must ensure that their defense materials can withstand prolonged exposure to heat without compromising their integrity. This is where testing for sustained heat exposure comes in a critical laboratory service that simulates real-world conditions to assess the performance of materials under extreme temperatures.

Advantages of Using Eurolabs Testing Services

By partnering with Eurolab, businesses operating in the defense industry can reap numerous benefits from our comprehensive testing services. Some of the key advantages include

Improved Material Reliability Our tests simulate real-world conditions to identify potential weaknesses and vulnerabilities in materials, allowing companies to make informed decisions about material selection and design.

Enhanced Safety and Security By assessing the performance of defense materials under sustained heat exposure, our testing services help ensure that equipment functions as intended, reducing the risk of accidents and injuries.

Cost Savings Our thorough testing procedures identify potential issues early on, preventing costly rework, replacements, or repairs down the line.

Compliance with Regulations Eurolabs testing services help businesses meet stringent industry regulations and standards, ensuring compliance with government requirements and minimizing the risk of non-compliance penalties.

Competitive Advantage Companies that invest in comprehensive testing services like ours can differentiate themselves from competitors by demonstrating a commitment to quality, safety, and reliability.

Key Benefits of Eurolabs Testing Services

Here are some key benefits of our testing services

Comprehensive Test Methods Our team employs a range of test methods, including thermal analysis, mechanical testing, and materials characterization, to assess the performance of defense materials under sustained heat exposure.

State-of-the-Art Equipment Eurolabs laboratory is equipped with cutting-edge equipment, ensuring that our tests are conducted with precision and accuracy.

Experienced Team Our experts have extensive knowledge and experience in the field of materials testing, guaranteeing that test results are reliable and actionable.

Customized Testing Programs We work closely with clients to develop tailored testing programs that meet their specific needs and requirements.

QA Frequently Asked Questions

Q1 What is sustained heat exposure?

A1 Sustained heat exposure refers to prolonged exposure to high temperatures, which can cause materials to degrade or fail.

Q2 Why is testing for sustained heat exposure essential in the defense industry?

A2 Testing for sustained heat exposure helps ensure that defense materials can withstand extreme temperatures without compromising their performance, reliability, or safety.

Q3 What types of materials are typically tested for sustained heat exposure?

A3 Our testing services cater to a wide range of materials used in the defense industry, including metals, polymers, ceramics, and composites.

Q4 How do your tests simulate real-world conditions?

A4 We employ a combination of test methods, including thermal analysis, mechanical testing, and materials characterization, to replicate real-world scenarios and assess material performance under sustained heat exposure.

Conclusion

In todays complex defense landscape, companies must prioritize the reliability, integrity, and safety of their products. Testing for sustained heat exposure on defense materials is an essential service that helps businesses mitigate risks, ensure compliance with regulations, and maintain a competitive edge.

At Eurolab, we are committed to providing top-notch laboratory services that cater to the unique needs of the defense industry. Our team of experts will work closely with clients to develop customized testing programs that meet their specific requirements. Dont compromise on material performance choose Eurolab for comprehensive and reliable testing services that ensure the safety and security of your defense materials.

Contact us today to learn more about our testing services and how we can help you protect your business from the risks associated with sustained heat exposure.