Testing the effect of rapid temperature changes on defense components

The Crucial Role of Testing the Effect of Rapid Temperature Changes on Defense Components Unlocking the Secrets of Performance and Reliability

In todays fast-paced defense industry, where innovation and technological advancements are pushing the boundaries of performance and reliability, it is essential for businesses to stay ahead of the curve. One critical aspect that often goes unnoticed yet plays a pivotal role in ensuring the effectiveness and longevity of defense components is testing their resilience against rapid temperature changes.

At Eurolab, we specialize in providing laboratory services that cater to the specific needs of the defense industry, including testing the effect of rapid temperature changes on defense components. This specialized service is more than just a necessity; its an opportunity for businesses to safeguard their investments by identifying potential vulnerabilities and implementing targeted improvements.

In this comprehensive article, we will delve into the world of thermal testing and explore its significance in maintaining peak performance and reliability within defense components. By understanding the benefits, we hope to inspire companies like yours to prioritize thermal testing as a vital component of their quality assurance protocols.

What is Testing the Effect of Rapid Temperature Changes on Defense Components?

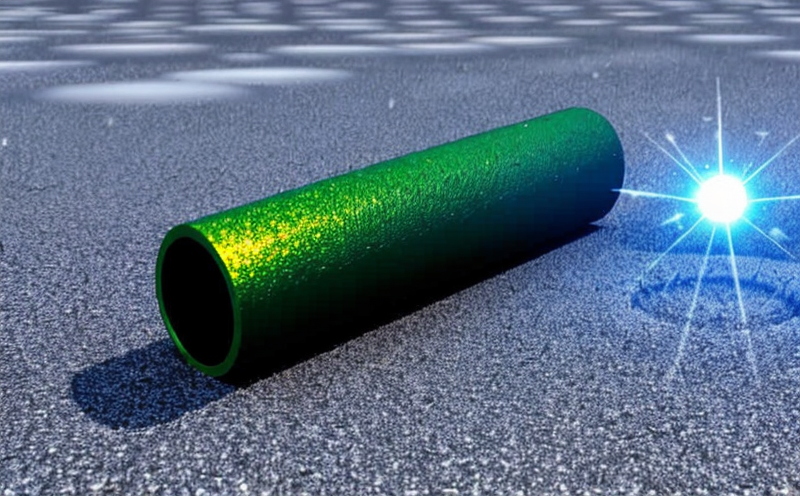

Thermal testing, or specifically testing the effect of rapid temperature changes on defense components, involves simulating extreme environmental conditions to evaluate a materials response. This includes exposing the component to temperatures ranging from cryogenic levels (near absolute zero) to high-temperature extremes, often in a matter of seconds.

The primary goal is to analyze how well the defense component withstands these drastic fluctuations, assessing its structural integrity and performance. By understanding its behavior under such conditions, manufacturers can pinpoint potential weaknesses, optimize material properties, and enhance overall reliability.

Why Testing the Effect of Rapid Temperature Changes on Defense Components Matters

Incorporating thermal testing into your quality control process offers numerous benefits that directly contribute to enhanced performance, longevity, and safety. Some key advantages include

Improved Reliability By identifying areas susceptible to temperature-related degradation or failure, you can make informed design decisions and adjustments, ensuring your components are better equipped to withstand the rigors of deployment.

Enhanced Performance Thermal testing reveals how different materials react under extreme conditions, enabling manufacturers to fine-tune their products for optimal performance in a wide range of environments.

Compliance with Regulations Many defense contracts specify thermal testing requirements. By incorporating this service into your testing regimen, you not only comply with regulatory demands but also demonstrate a commitment to quality and reliability.

Cost Savings While the initial investment in thermal testing may seem daunting, it is significantly more cost-effective than dealing with component failures or recalls, both of which can have serious financial implications.

Some key benefits are summarized below

Improved performance under extreme conditions

Enhanced structural integrity and durability

Compliance with industry standards and regulations

Reduced risk of component failure and associated costs

QA Understanding Testing the Effect of Rapid Temperature Changes on Defense Components

Q What types of components benefit from thermal testing?

A Any defense-related component, including but not limited to electronics, mechanical parts, and materials used in military hardware.

Q How are rapid temperature changes simulated in a laboratory setting?

A Eurolab employs specialized equipment capable of rapid cooling or heating, allowing for precise control over the thermal conditions applied to components during testing.

Q What kind of data can I expect from thermal testing?

A Youll receive comprehensive reports detailing how your component reacts under various temperature conditions, including structural integrity assessments and suggestions for material improvements.

Q Can you provide an example of a successful application of this service?

A Yes. A prominent defense contractor partnered with Eurolab to test their advanced missile guidance system components against rapid temperature changes. Our findings led to critical design adjustments that significantly improved the systems reliability and performance.

Conclusion

In the dynamic world of defense technology, the importance of testing the effect of rapid temperature changes on defense components cannot be overstated. By incorporating this crucial service into your quality control protocols, manufacturers can not only ensure compliance with regulatory requirements but also unlock unparalleled levels of performance and reliability in their products.

At Eurolab, our team of experts is dedicated to providing comprehensive laboratory services tailored to the unique needs of the defense industry. If youre seeking a trusted partner to help navigate the complex world of thermal testing, we invite you to explore the possibilities with us.

Remember, in an industry where performance and reliability are paramount, investing in thermal testing can mean the difference between success and failure. Dont wait until its too late contact Eurolab today to discover how our laboratory services can fortify your defense components against the unpredictable forces of rapid temperature changes.