Testing for the risk of internal damage or short circuits from vibrations

The Hidden Dangers of Vibrations Why Testing for Internal Damage is Crucial for Your Business

In todays fast-paced industrial landscape, machinery and equipment are subjected to various forms of stress, including vibrations. While these may seem harmless, they can lead to internal damage or short circuits, resulting in costly downtime, damaged products, and even injuries. Thats where Eurolab comes in a leading laboratory service provider that specializes in testing for the risk of internal damage or short circuits from vibrations.

In this article, well delve into the importance of vibration testing, its benefits, and why its an essential service for businesses across various industries. Well also address common questions and concerns you may have about this critical laboratory service.

What is Testing for Internal Damage or Short Circuits from Vibrations?

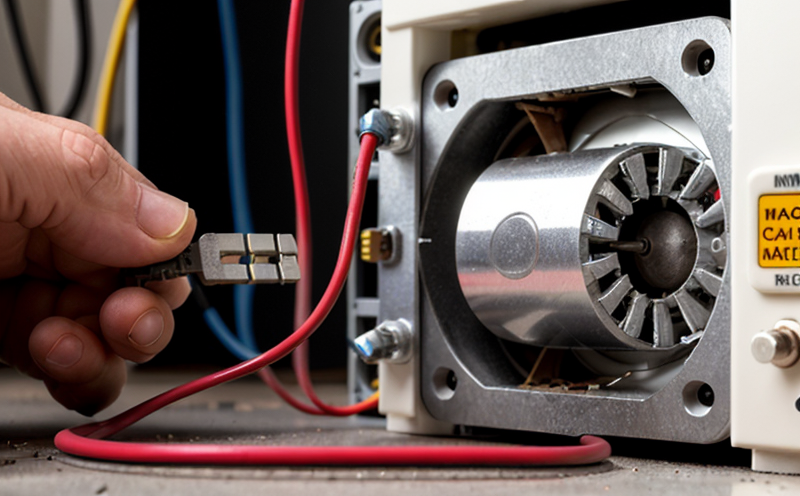

Testing for internal damage or short circuits from vibrations involves analyzing the effects of mechanical stress on a products internal components. This non-destructive testing method helps identify potential vulnerabilities, allowing manufacturers to take preventive measures and ensure their products meet safety standards. At Eurolab, our team of experts uses advanced equipment and techniques to simulate real-world vibration scenarios, providing an accurate assessment of a products resilience.

The Advantages of Using Testing for Internal Damage or Short Circuits from Vibrations

Eurolabs vibration testing services offer numerous benefits that can have a significant impact on your business. Here are some key advantages

Prevents Equipment Failure Regular vibration testing helps identify potential issues before they cause equipment failure, minimizing downtime and reducing maintenance costs.

Enhances Product Safety By detecting internal damage or short circuits, you can ensure your products meet regulatory requirements and avoid costly recalls.

Improves Quality Control Vibration testing enables manufacturers to refine their production processes, leading to higher-quality products that meet customer expectations.

Reduces Energy Consumption Optimized equipment performance through vibration testing can lead to energy savings, reducing environmental impact and lowering operational costs.

Compliance with Industry Standards Our laboratory services ensure your products comply with industry-specific regulations, such as those set by the International Organization for Standardization (ISO).

Cost Savings Identifying and addressing internal damage or short circuits early on saves you money in the long run by avoiding costly repairs, replacements, and potential lawsuits.

Increased Customer Satisfaction By delivering high-quality products that meet safety standards, youll enhance customer satisfaction and build brand loyalty.

How Does Eurolabs Vibration Testing Service Work?

Our team uses a combination of advanced equipment and techniques to simulate real-world vibration scenarios. The process typically involves

Product Analysis We examine your products design and materials to understand its potential vulnerabilities.

Vibration Simulation Our laboratory equipment simulates various vibration scenarios, including sinusoidal, random, and shock loads.

Data Collection Advanced sensors and software collect data on the products response to vibrations, including internal damage or short circuits.

Report Generation We provide a detailed report outlining our findings, recommendations for improvement, and any necessary corrective actions.

QA Common Questions about Vibration Testing

Q What types of products benefit from vibration testing?

A Any product subject to mechanical stress can benefit from vibration testing, including machinery, equipment, vehicles, aerospace components, and more.

Q How often should I conduct vibration testing on my products?

A Regular vibration testing is essential for products that are prone to vibrations or have experienced previous failures. We recommend testing your products at various stages of production and maintenance.

Q What types of equipment do you use for vibration testing?

A Our laboratory is equipped with state-of-the-art equipment, including electrodynamic shakers, hydraulic shakers, and advanced sensors, ensuring accurate and reliable results.

Q Can I trust Eurolabs test results?

A Absolutely. Our team of experts uses internationally recognized standards and protocols to ensure the accuracy and reliability of our test results. We also provide comprehensive reports and recommendations for improvement.

Conclusion

In todays competitive industrial landscape, companies can no longer afford to overlook the risks associated with vibrations. Eurolabs vibration testing services provide a proactive approach to ensuring product safety, quality control, and compliance with industry standards. By partnering with us, youll not only prevent costly equipment failures but also enhance customer satisfaction, reduce energy consumption, and lower operational costs.

Dont let hidden dangers compromise your business. Contact Eurolab today to schedule a vibration testing service and take the first step towards a safer, more efficient, and more profitable operation.