Vibration testing for batteries used in military and aerospace environments

Vibration Testing for Batteries in Military and Aerospace Environments Ensuring Reliability and Performance

In the fast-paced world of military and aerospace operations, reliability and performance are paramount. The demands placed on batteries used in these environments are extreme, with exposure to intense vibrations, temperatures, and other harsh conditions that can quickly render even the most robust batteries ineffective.

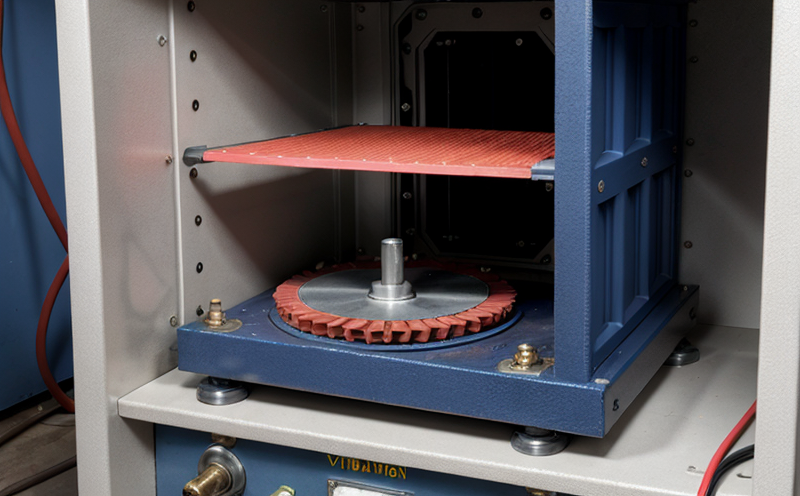

Vibration testing for batteries used in military and aerospace environments is a critical laboratory service that ensures these essential components meet the rigorous standards required by the industry. At Eurolab, our team of experts provides comprehensive vibration testing services designed to simulate the toughest environmental conditions, guaranteeing that batteries perform flawlessly even under the most extreme circumstances.

The Importance of Vibration Testing for Military and Aerospace Batteries

In military and aerospace applications, batteries are often subjected to intense vibrations caused by launch, flight, or other operational stresses. These vibrations can lead to premature battery failure, resulting in catastrophic consequences, including equipment malfunction, loss of mission critical functions, and even accidents.

To mitigate these risks, manufacturers must ensure that their batteries meet the stringent standards required by military and aerospace organizations. Vibration testing is a crucial step in this process, providing valuable insights into a batterys performance under simulated environmental conditions.

Advantages of Using Vibration Testing for Military and Aerospace Batteries

Our vibration testing services offer numerous benefits to businesses operating in the military and aerospace sectors, including

Improved Reliability By simulating extreme vibrations, our tests identify potential weaknesses in battery design or construction, enabling manufacturers to address these issues before they result in field failures.

Enhanced Performance Vibration testing ensures that batteries operate within specified parameters even under intense environmental conditions, guaranteeing reliable performance and minimizing the risk of equipment malfunction.

Reduced Costs Identifying and addressing vibration-related issues early on saves manufacturers time and resources, reducing costs associated with product redesign, re-testing, and warranty claims.

Increased Efficiency Our vibration testing services help optimize battery design and construction, enabling manufacturers to create more efficient and effective products that meet the demanding requirements of military and aerospace applications.

Compliance with Regulations By partnering with Eurolab for vibration testing, manufacturers can ensure compliance with relevant industry standards and regulations, mitigating the risk of non-compliance and related consequences.

Key Benefits of Vibration Testing

Our comprehensive vibration testing services include

Simulation of Extreme Environments Our state-of-the-art equipment simulates a range of environmental conditions, including high-temperature and high-vibration scenarios.

Multi-Axis Vibration Testing We provide multi-axis vibration testing to simulate the complex vibrations experienced by batteries in real-world applications.

Battery Performance Analysis Our expert analysts assess battery performance under various vibration conditions, providing detailed insights into their reliability and efficiency.

Customized Test Protocols We work closely with manufacturers to develop customized test protocols that meet specific industry requirements.

Frequently Asked Questions

At Eurolab, we understand that our customers may have questions about our vibration testing services. Below are some frequently asked questions and answers

Q What types of batteries do you offer vibration testing for?

A We provide vibration testing for a range of battery types, including lithium-ion, nickel-cadmium, and lead-acid.

Q How does your vibration testing process work?

A Our process involves simulating extreme environmental conditions using state-of-the-art equipment. We then analyze the results to identify potential weaknesses in battery design or construction.

Q What industries do you serve with vibration testing services?

A We provide vibration testing services for a range of industries, including military and aerospace.

Q Can I customize your test protocols to meet specific industry requirements?

A Yes. Our expert analysts work closely with manufacturers to develop customized test protocols that meet specific industry requirements.

Conclusion

In the high-stakes world of military and aerospace operations, reliability and performance are paramount. Vibration testing for batteries used in these environments is a critical laboratory service that ensures these essential components meet the rigorous standards required by the industry.

At Eurolab, our team of experts provides comprehensive vibration testing services designed to simulate the toughest environmental conditions, guaranteeing that batteries perform flawlessly even under the most extreme circumstances. By partnering with us for vibration testing, manufacturers can ensure improved reliability, enhanced performance, reduced costs, and increased efficiency all while ensuring compliance with relevant industry standards and regulations.

Dont risk equipment malfunction or loss of mission critical functions due to poorly performing batteries. Trust Eurolabs expertise in vibration testing services to give you the confidence that your military and aerospace batteries meet the highest standards of reliability and performance. Contact us today to learn more about our comprehensive vibration testing services!