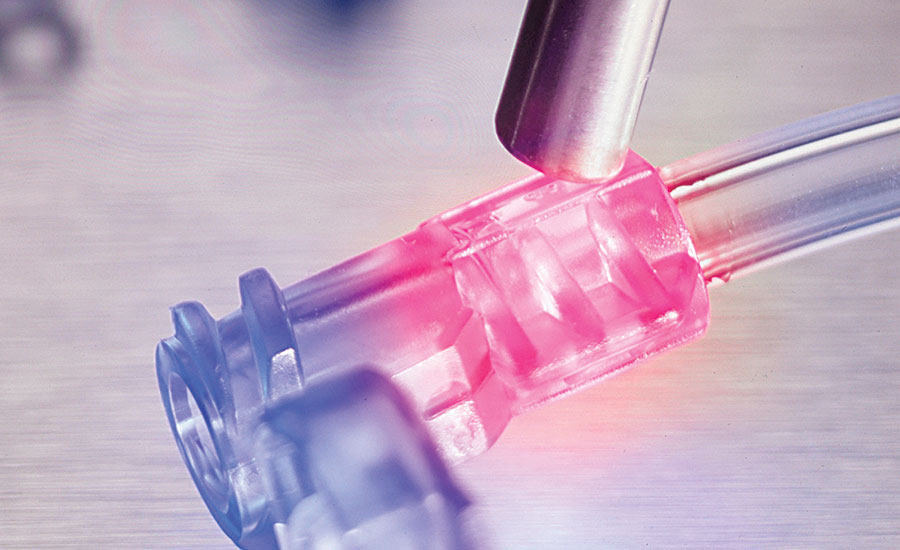

Testing for UV stability in medical adhesives

The Crucial Role of UV Stability Testing in Medical Adhesives Ensuring Long-Term Reliability and Safety

In the field of medical adhesives, manufacturers face a multitude of challenges to ensure their products meet the stringent requirements for patient safety and efficacy. One critical aspect that often goes unnoticed is the testing for UV stability, which plays a vital role in guaranteeing the long-term reliability and performance of these materials. As the demand for medical adhesives continues to rise, it has become increasingly essential for companies to incorporate UV stability testing into their quality control protocols.

At Eurolab, we specialize in providing comprehensive laboratory services, including rigorous testing for UV stability in medical adhesives. Our state-of-the-art facilities and expert personnel ensure that our clients receive accurate, reliable results that meet the highest industry standards.

Why is Testing for UV Stability Essential?

Medical adhesives are subjected to various environmental conditions, including exposure to ultraviolet (UV) radiation. This can cause a range of negative effects on the materials properties, such as

Loss of adhesive strength

Degradation of mechanical properties

Alterations in color or optical clarity

Changes in chemical composition

These changes can compromise the safety and efficacy of the medical adhesive, leading to suboptimal performance or even patient harm. By testing for UV stability, manufacturers can identify potential issues early on and take corrective measures to ensure their products meet regulatory requirements.

Advantages of Using Testing for UV Stability in Medical Adhesives

Incorporating UV stability testing into your quality control protocols offers numerous benefits, including

Ensures Long-Term Reliability and Performance

UV stability testing helps manufacturers identify potential issues that may arise during the products lifespan, ensuring that medical adhesives maintain their intended properties over time.

Reduces the risk of product failure or recall

Minimizes costs associated with rework or waste

Enhances Patient Safety and Efficacy

By guaranteeing the UV stability of medical adhesives, manufacturers can ensure that their products are safe for use and effective in promoting healing or treating conditions.

Complies with regulatory requirements

Builds trust with customers and stakeholders

Supports Regulatory Compliance

UV stability testing helps manufacturers meet industry standards and regulations, such as ISO 10993-52009(E) and IEC 60825-

Minimizes the risk of non-compliance

Demonstrates a commitment to quality and safety

Reduces Costs and Improves Efficiency

By identifying potential issues early on, manufacturers can reduce costs associated with rework or waste and improve their overall efficiency.

Optimizes production processes

Enhances supply chain management

QA Frequently Asked Questions about Testing for UV Stability in Medical Adhesives

What is UV stability testing?

UV stability testing involves exposing medical adhesives to controlled levels of ultraviolet radiation to evaluate their ability to maintain their intended properties.

Why is UV stability testing important for medical adhesives?

UV stability testing helps manufacturers identify potential issues that may arise during the products lifespan, ensuring that medical adhesives maintain their intended properties over time.

What are the benefits of using UV stability testing in medical adhesives?

The benefits of using UV stability testing in medical adhesives include enhanced patient safety and efficacy, regulatory compliance, reduced costs, and improved efficiency.

How can I ensure that my medical adhesives meet industry standards and regulations?

By incorporating UV stability testing into your quality control protocols, you can ensure that your medical adhesives meet industry standards and regulations.

Conclusion

Testing for UV stability in medical adhesives is a critical aspect of ensuring long-term reliability and safety. At Eurolab, we provide comprehensive laboratory services to help manufacturers identify potential issues early on and take corrective measures to ensure their products meet regulatory requirements. By incorporating UV stability testing into your quality control protocols, you can enhance patient safety and efficacy, reduce costs, and improve efficiency.

We invite you to learn more about our laboratory services and how we can support your business needs. Our team of experts is dedicated to providing accurate, reliable results that meet the highest industry standards. Together, lets ensure the long-term reliability and performance of medical adhesives.