UV degradation in adhesives for electronics

The Hidden Threat to Electronics Understanding UV Degradation in Adhesives

As the demand for electronic devices continues to soar, manufacturers are under increasing pressure to deliver products that meet the highest standards of performance and durability. However, one often-overlooked threat to these devices is UV degradation in adhesives a process that can compromise the integrity of electronics and lead to costly failures.

At Eurolab, we specialize in laboratory services that help businesses like yours mitigate this risk. By understanding the causes and consequences of UV degradation in adhesives for electronics, youll be better equipped to protect your products and reputation.

What is UV Degradation in Adhesives?

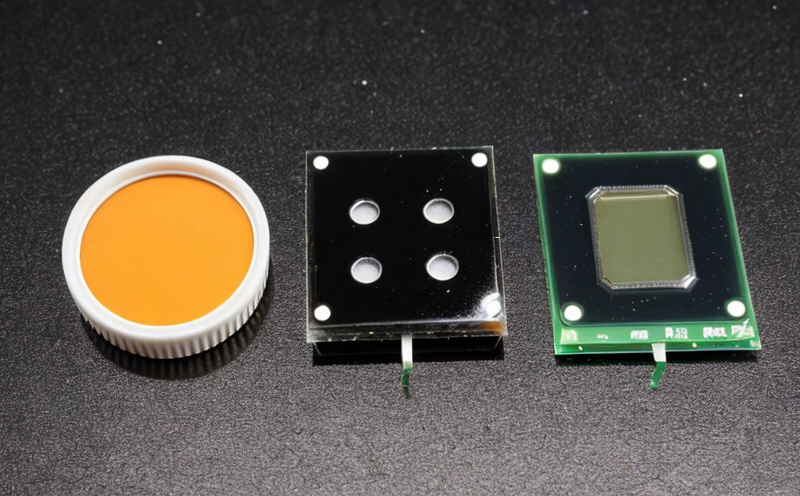

UV degradation occurs when ultraviolet (UV) radiation breaks down the molecular structure of adhesive materials, leading to a loss of their optical, thermal, or electrical properties. This can cause adhesives to become brittle, discolored, or even crack, compromising the bond between components and ultimately affecting the performance and lifespan of electronic devices.

The Importance of Testing for UV Degradation

Given its potential to impact product reliability and safety, its essential that manufacturers take steps to identify and mitigate UV degradation in adhesives. Eurolabs laboratory services provide a critical solution by helping you

Detect potential issues early Our expert technicians use advanced equipment to simulate real-world UV exposure conditions, allowing us to identify any potential problems before they become major concerns.

Optimize adhesive formulation By analyzing the effects of UV radiation on your adhesives, we can help you develop more resilient formulations that withstand the rigors of environmental exposure.

Ensure regulatory compliance Our testing services enable you to meet or exceed industry standards for electronic device reliability and performance.

The Benefits of Using Eurolabs UV Degradation in Adhesives Service

Here are just a few key advantages of working with Eurolab

Improved Product Reliability By identifying and addressing potential issues related to UV degradation, you can reduce the risk of product failure and ensure that your electronics meet or exceed customer expectations.

Enhanced Safety Performance Our testing services help you develop adhesives that can withstand environmental stresses, reducing the likelihood of safety-related issues and minimizing liability.

Reduced Warranty Claims and Returns By identifying potential problems early on, we enable manufacturers to implement corrective measures, thereby reducing warranty claims and returns.

Compliance with Industry Standards Our laboratory services ensure that your products meet or exceed industry standards for electronic device reliability and performance.

QA Frequently Asked Questions About UV Degradation in Adhesives

Here are some answers to common questions about UV degradation in adhesives

Q What causes UV degradation in adhesives?

A Ultraviolet (UV) radiation breaks down the molecular structure of adhesive materials, leading to a loss of their optical, thermal, or electrical properties.

Q How does Eurolab test for UV degradation?

A Our expert technicians use advanced equipment to simulate real-world UV exposure conditions, allowing us to identify any potential problems before they become major concerns.

Q What are the consequences of neglecting UV degradation in adhesives?

A Ignoring UV degradation can lead to product failure, safety-related issues, and costly warranty claims or returns.

Q Can Eurolab help me develop more resilient adhesive formulations?

A Yes! By analyzing the effects of UV radiation on your adhesives, we can help you develop more durable and reliable formulations that withstand environmental exposure.

Conclusion

UV degradation in adhesives is a critical issue that can have far-reaching consequences for electronic device manufacturers. By partnering with Eurolabs laboratory services, you can ensure that your products meet or exceed industry standards for reliability, safety, and performance.

Dont let UV degradation compromise your reputation or bottom line. Trust the experts at Eurolab to help you develop more resilient adhesives and protect your electronics from environmental stressors.

Get in Touch with Eurolab

At Eurolab, were committed to delivering high-quality laboratory services that meet the unique needs of each client. Whether youre a seasoned manufacturer or just starting out, our expert technicians are here to help you navigate the complex world of UV degradation in adhesives.

Let us help you safeguard your products and reputation with confidence. Contact Eurolab today to learn more about how we can support your business needs.