Testing the durability of aerospace seals and gaskets under thermal cycling conditions

Unlocking the Secrets of Aerospace Seals and Gaskets Why Testing Durability Under Thermal Cycling Conditions is Crucial

In the world of aerospace engineering, the reliability of seals and gaskets can be a matter of life and death. The slightest compromise in their performance can have devastating consequences, from system failure to catastrophic accidents. Thats why testing the durability of aerospace seals and gaskets under thermal cycling conditions is an indispensable service for businesses involved in the design, development, and production of aerospace components.

At Eurolab, we specialize in providing a comprehensive laboratory service that ensures the integrity and reliability of your critical aerospace components. Our team of expert technicians and scientists employ state-of-the-art equipment to simulate real-world operating conditions, including thermal cycling tests. By doing so, we help you avoid costly downtime, reduce the risk of accidents, and ultimately save lives.

What is Thermal Cycling Testing?

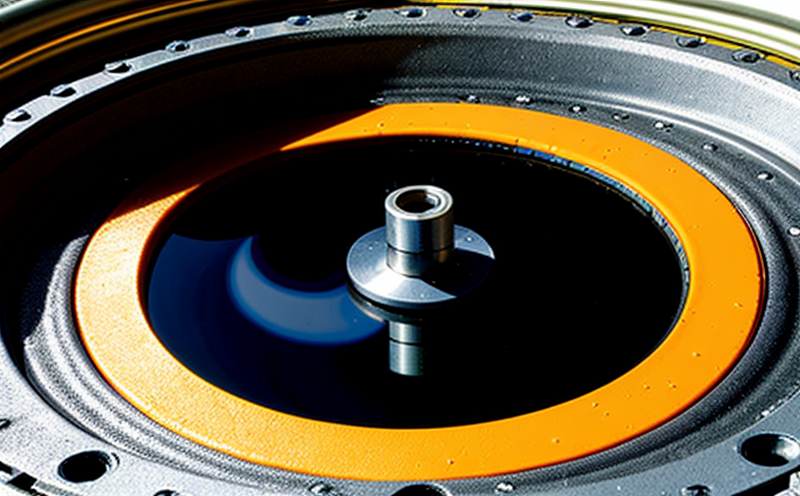

Thermal cycling testing involves subjecting materials or components to repeated cycles of extreme temperatures, typically from -50C to 150C or higher. This process simulates the thermal stresses that aerospace seals and gaskets experience during normal operation, as well as during extreme conditions such as launch or re-entry. By testing under these conditions, we can evaluate the durability and performance of your materials in a controlled environment.

Why is Thermal Cycling Testing Essential for Aerospace Seals and Gaskets?

The importance of thermal cycling testing cannot be overstated. Here are just some of the key benefits

Improved Reliability Thermal cycling testing helps identify potential weaknesses or failures that may occur under extreme temperature conditions.

Reduced Risk By simulating real-world operating conditions, we can ensure your aerospace seals and gaskets meet the highest standards of reliability and performance.

Cost Savings Identifying and addressing issues before they become a problem saves time, money, and resources in the long run.

Enhanced Safety By ensuring the integrity of your critical components, we help reduce the risk of accidents and minimize potential damage.

Key Benefits of Eurolabs Thermal Cycling Testing Services

At Eurolab, our thermal cycling testing services are designed to provide you with a comprehensive understanding of your aerospace seals and gaskets performance under various conditions. Here are some key benefits

Advanced Equipment Our state-of-the-art equipment allows us to simulate complex thermal stress scenarios, providing accurate and reliable results.

Expert Analysis Our team of experienced technicians and scientists will analyze your test data to identify areas for improvement and provide actionable recommendations.

Customized Testing Programs We work closely with you to develop customized testing programs tailored to your specific needs and requirements.

Rapid Turnaround Times Our efficient testing protocols ensure fast turnaround times, allowing you to quickly incorporate the results into your design or production process.

QA Frequently Asked Questions About Thermal Cycling Testing

Q What types of materials can be tested using thermal cycling testing?

A We test a wide range of materials, including elastomers (e.g., O-rings, gaskets), metals, and other aerospace-specific materials.

Q How do you simulate thermal cycling conditions in the laboratory?

A Our state-of-the-art equipment allows us to control temperature, pressure, and other environmental factors to accurately replicate real-world operating conditions.

Q What types of tests can be performed using thermal cycling testing?

A We offer a range of test protocols, including static seal tests, dynamic seal tests, and material characterization tests.

Q Can I witness the testing process or review the results in detail?

A Yes, we offer on-site observation and detailed reporting to ensure you have complete visibility into your materials performance under thermal cycling conditions.

Conclusion

In the high-stakes world of aerospace engineering, the reliability of seals and gaskets can be a matter of life and death. By testing the durability of aerospace seals and gaskets under thermal cycling conditions, Eurolab provides you with the peace of mind that comes with knowing your critical components meet the highest standards of performance and safety.

Dont risk your businesss reputation or safety record on substandard materials. Trust Eurolab to provide you with expert analysis, advanced equipment, and customized testing programs tailored to your specific needs. Contact us today to learn more about our thermal cycling testing services and discover how we can help you unlock the secrets of aerospace seals and gaskets.

Get a Quote for Our Thermal Cycling Testing Services

Take the first step towards ensuring the reliability and performance of your critical aerospace components. Fill out our online quote form, and one of our experts will be in touch to discuss your specific testing needs and requirements.