Thermal cycling testing for aerospace adhesives and bonding materials

Unlocking Reliability The Crucial Role of Thermal Cycling Testing for Aerospace Adhesives and Bonding Materials

In the aerospace industry, reliability is paramount. The stakes are high, and even a small failure can have catastrophic consequences. One critical aspect of ensuring the integrity of aerospace adhesives and bonding materials is thermal cycling testing. This rigorous laboratory service, provided by Eurolab, simulates the extreme temperature fluctuations that these materials will encounter during flight, allowing manufacturers to verify their performance under conditions that mimic real-world environments.

Thermal cycling testing for aerospace adhesives and bonding materials is a sophisticated evaluation method that subjectively assesses an adhesives resistance to thermal fatigue. This critical test exposes the material to repeated cycles of heating and cooling, pushing its limits to determine how well it withstands these stressors. By simulating various temperature profiles, manufacturers can identify potential weaknesses and areas for improvement in their formulations.

Why Thermal Cycling Testing Matters

In todays competitive aerospace landscape, meeting regulatory standards is no longer enough. Manufacturers must continually strive for excellence, ensuring that their products not only comply with regulations but also outperform expectations. This is where thermal cycling testing comes into play

Predictive Maintenance By simulating real-world temperature fluctuations, manufacturers can identify potential failure points before they occur in service.

Cost Savings Thermal cycling testing helps prevent costly rework or replacement of materials that may not meet performance requirements.

Improved Performance Manufacturers can refine their adhesive formulations to optimize thermal stability and reliability.

Benefits of Eurolabs Thermal Cycling Testing Service

At Eurolab, our team of experts is dedicated to delivering high-quality laboratory services tailored to the unique needs of aerospace manufacturers. Our comprehensive thermal cycling testing service offers numerous benefits

Customized Test Programs Collaborate with our experienced engineers to design test programs that precisely replicate your products operating conditions.

Accurate Data Analysis Receive detailed reports and data analysis, allowing you to make informed decisions about material performance and improvement strategies.

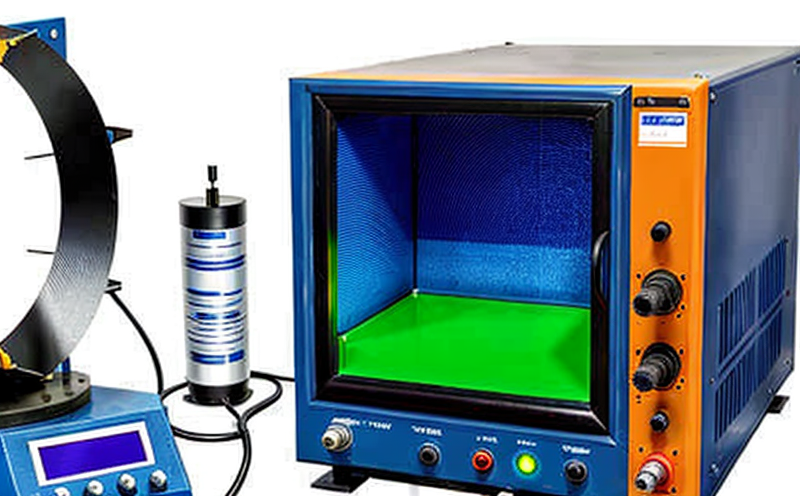

State-of-the-Art Facilities Our laboratory is equipped with cutting-edge equipment and technology to ensure accurate and reliable results.

Why Choose Eurolab for Thermal Cycling Testing?

With years of experience in the aerospace industry, our team has developed a deep understanding of the challenges and complexities involved. We offer

Expertise Our staff includes seasoned engineers and technicians who have worked with numerous high-profile aerospace clients.

Reliability Our laboratory is equipped to handle a wide range of test procedures, ensuring consistency and accuracy in all results.

Confidentiality Your data and intellectual property are safeguarded by our strict confidentiality policies.

Thermal Cycling Testing The Science Behind the Process

Understanding how thermal cycling testing works is essential for manufacturers looking to improve their products. This rigorous evaluation involves

Temperature Control A controlled temperature environment is established, simulating various profiles of heating and cooling.

Cycling Protocols Customized test programs are designed to mimic real-world operating conditions, including exposure to extreme temperatures, humidity, and other environmental factors.

Material Evaluation The adhesive or bonding material is subjected to repeated cycles of thermal stress, allowing for observation of its resistance to thermal fatigue.

Frequently Asked Questions

Q What types of materials can be tested using thermal cycling testing?

A Eurolabs thermal cycling testing service is suitable for a wide range of aerospace adhesives and bonding materials, including but not limited to epoxy-based, polyurethane-based, and acrylic-based systems.

Q Can thermal cycling testing simulate environmental conditions such as humidity or vibration?

A Yes. Our laboratory equipment can accommodate various test protocols that include exposure to specific environmental factors, ensuring a comprehensive assessment of your products performance.

Q How long does a typical thermal cycling test take?

A The duration of the test depends on the specific requirements and temperature profiles used in each case study. In general, our tests can last anywhere from several hours to several days or even weeks.

Conclusion

Thermal cycling testing is an indispensable tool for manufacturers seeking to ensure the reliability and integrity of their aerospace adhesives and bonding materials. At Eurolab, we understand the complexities involved in this rigorous evaluation process and are dedicated to providing expert support throughout every step. By partnering with our team, you can gain valuable insights into your products performance under real-world conditions, driving innovation and excellence in the aerospace industry.

Getting Started

Eurolab is committed to delivering high-quality laboratory services tailored to meet the unique needs of each client. If you are interested in learning more about our thermal cycling testing service or would like to discuss a potential project, please dont hesitate to contact us.