Testing the insulation and grounding of electrical components in household appliances and electronics

Testing the Insulation and Grounding of Electrical Components Ensuring Safety and Efficiency in Household Appliances and Electronics

As a business owner, you understand the importance of maintaining high-quality products to build trust with your customers and stay competitive in the market. One critical aspect of ensuring product quality is testing the insulation and grounding of electrical components in household appliances and electronics. This laboratory service, offered by Eurolab, is essential for businesses that want to guarantee the safety and efficiency of their products.

What is Testing the Insulation and Grounding of Electrical Components?

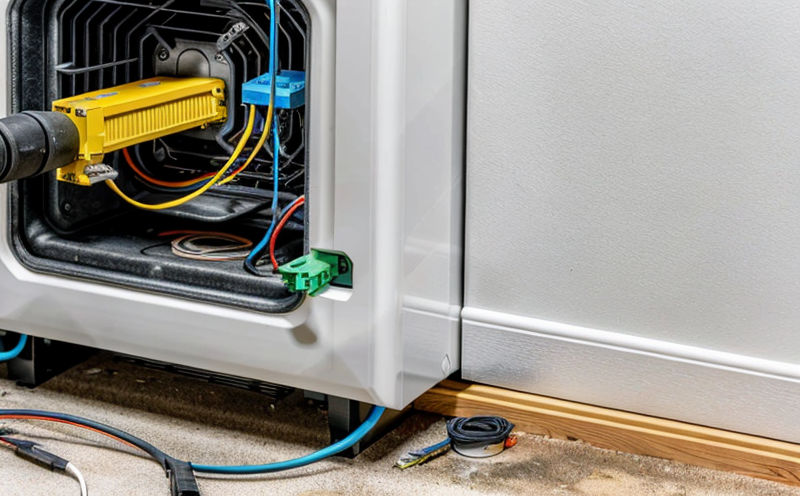

Testing the insulation and grounding of electrical components involves evaluating the ability of a products internal circuits to prevent short-circuits, overheating, and other potential hazards. This process ensures that your products meet international standards for safety and performance, reducing the risk of electrical shock, fires, and other accidents.

Why is Testing the Insulation and Grounding of Electrical Components Essential?

The insulation and grounding testing service offered by Eurolab provides numerous benefits to businesses, including

Advantages of Using Eurolabs Insulation and Grounding Testing Services

Improved Product Safety By identifying potential electrical hazards, you can prevent accidents and ensure consumer safety.

Compliance with International Standards Our testing services help your products meet international standards for safety and performance, reducing the risk of product recalls and damage to your reputation.

Increased Efficiency Identifying and addressing electrical issues early on reduces the likelihood of costly repairs and downtime.

Reduced Liability By ensuring your products meet safety standards, you can minimize liability and protect your business from potential lawsuits.

Enhanced Brand Reputation Demonstrating a commitment to product safety and quality reinforces your brands reputation for excellence.

Benefits for Businesses

Cost Savings Our testing services help identify potential issues early on, reducing the likelihood of costly repairs and downtime.

Increased Customer Trust By prioritizing product safety, you build trust with your customers and establish a reputation for quality and reliability.

Competitive Advantage Demonstrating a commitment to product safety and quality sets your business apart from competitors and reinforces your brands reputation.

Benefits for Consumers

Peace of Mind Knowing that products have been tested for electrical safety provides consumers with peace of mind and confidence in their purchases.

Protection from Electrical Hazards Our testing services help prevent accidents and ensure consumer safety, reducing the risk of electrical shock and other hazards.

Quality Products By prioritizing product safety and quality, businesses can offer customers high-quality products that meet their needs.

Benefits for Regulatory Compliance

Meets International Safety Standards Eurolabs testing services help your products meet international standards for safety and performance.

Reduces Risk of Product Recalls Identifying potential electrical issues early on reduces the risk of product recalls and damage to your reputation.

Demonstrates Commitment to Quality By prioritizing regulatory compliance, businesses can demonstrate a commitment to quality and excellence.

Benefits for Industry Certifications

Enhanced Industry Recognition Demonstrating a commitment to product safety and quality reinforces your businesss reputation within the industry.

Improved Supply Chain Relationships Prioritizing product safety and quality helps establish strong relationships with suppliers and partners.

Increased Market Share By prioritizing regulatory compliance, businesses can increase market share and stay competitive.

Frequently Asked Questions

Q What types of products require insulation and grounding testing?

A Our laboratory services are suitable for a wide range of household appliances and electronics, including but not limited to refrigerators, air conditioners, washing machines, dishwashers, televisions, computers, and smartphones.

Q How do I prepare my product for testing?

A Please contact our team to discuss specific preparation requirements for your product. We will provide detailed instructions on how to ensure accurate and reliable test results.

Q What types of tests are included in the insulation and grounding testing service?

A Our comprehensive testing package includes a range of electrical safety tests, including insulation resistance, leakage current, and earth continuity testing.

Q How long does the testing process take?

A The duration of the testing process varies depending on the complexity of your product. On average, our laboratory services take 2-5 business days to complete.

Q Can I request additional testing or certification services?

A Yes! Our team offers a range of additional testing and certification services, including environmental testing, EMC testing, and more. Please contact us to discuss your specific needs and requirements.

Conclusion

In todays competitive market, businesses must prioritize product safety and quality to build trust with customers and stay ahead of the competition. Eurolabs insulation and grounding testing service is an essential tool for businesses looking to ensure their products meet international standards for safety and performance. By choosing our laboratory services, you can

Improve product safety

Enhance brand reputation

Increase efficiency

Reduce liability

Dont wait until its too late prioritize your customers safety and trust with Eurolabs comprehensive testing services. Contact us today to learn more about how we can help your business thrive!

-

Evaluating the electrical safety of consumer products to prevent shock, short circuits, or fires

-

Verifying the compliance of electrical products with safety standards to prevent electric hazards

-

Simulating electrical faults or failures to assess the risk of electrical shock or fire in consumer products

-

Testing the protection mechanisms in place to ensure safe operation of electrical circuits in devices

-

Assessing the effectiveness of circuit breakers, fuses, or other safety devices in electrical products

-

Simulating accidental electrical surges or power failures to test the resilience of devices

-

Testing the resistance of electrical wiring and components to wear and degradation over time

-

Evaluating the safe handling of electrical products, including exposed wires or connections

-

Testing for the durability and safety of electrical connectors, plugs, and sockets used in consumer products

-

Ensuring that products have proper earthing and insulation to protect users from electric shock

-

Verifying that electrical appliances are free from harmful electromagnetic interference (EMI) or electromagnetic fields (EMF)

-

Testing the performance of safety features like thermal fuses or automatic shut-off systems in electrical products

-

Assessing electrical safety in battery-powered consumer goods to ensure they do not overheat or cause fires

-

Testing the integrity of electrical shielding or covers to prevent accidental contact with live parts

-

Verifying that products comply with global electrical safety certifications and standards

-

Assessing the durability of electrical components under conditions such as humidity, heat, or vibration

-

Simulating long-term usage to test the reliability of electrical systems in consumer devices

-

Testing the protection of user interfaces like buttons or screens from electrical risks

-

Evaluating the safety of electrical power supplies used in consumer goods like kitchen appliances or power tools

-

Ensuring that electrical systems in products are adequately tested for shock, fire, and overload protection