Testing the resistance of electrical wiring and components to wear and degradation over time

The Importance of Testing Electrical Wiring and Components Ensuring Long-Term Reliability and Efficiency

In todays fast-paced industrial landscape, businesses are constantly seeking ways to optimize their operations, reduce costs, and minimize downtime. One crucial aspect that often gets overlooked is the testing of electrical wiring and components for wear and degradation over time. At Eurolab, we understand the significance of this laboratory service in ensuring the long-term reliability and efficiency of electrical systems. In this article, well delve into the importance of testing the resistance of electrical wiring and components to wear and degradation over time, highlighting its advantages and answering frequently asked questions.

What is Testing the Resistance of Electrical Wiring and Components?

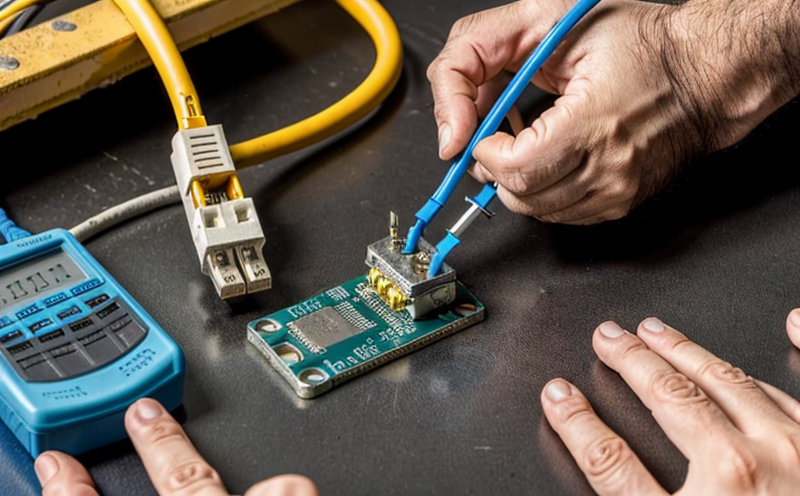

Testing the resistance of electrical wiring and components involves subjecting them to a series of rigorous tests to determine their ability to withstand the stresses and strains of everyday use. This laboratory service evaluates the physical, chemical, and electrical properties of materials used in electrical systems, including cables, wires, connectors, and switches. By simulating various operating conditions, such as temperature fluctuations, humidity, and mechanical stress, we can assess a components susceptibility to wear, degradation, and failure.

Why is Testing the Resistance of Electrical Wiring and Components Essential for Businesses?

In todays highly competitive market, businesses cannot afford to compromise on reliability or efficiency. Electrical systems are critical components of industrial operations, and their failure can lead to costly downtime, production losses, and even safety hazards. Regular testing of electrical wiring and components helps identify potential issues before they arise, ensuring the smooth operation of equipment and minimizing maintenance costs.

Advantages of Using Testing the Resistance of Electrical Wiring and Components

Our laboratory service offers numerous benefits for businesses seeking to optimize their electrical systems

Predictive Maintenance By identifying potential weaknesses, you can schedule maintenance and repairs in advance, reducing downtime and increasing overall efficiency.

Cost Savings Regular testing helps prevent costly failures, reducing maintenance costs and minimizing the need for expensive replacements.

Improved Safety By detecting safety hazards before they occur, you can ensure a safer working environment for your employees and reduce liability risks.

Enhanced Product Quality Testing electrical components ensures that only high-quality materials are used in production, maintaining your brands reputation for excellence.

Compliance with Regulations Our testing services help you meet regulatory requirements, avoiding fines and reputational damage associated with non-compliance.

Key Benefits of Eurolabs Laboratory Service

At Eurolab, we offer a comprehensive range of laboratory services tailored to the specific needs of your business. Our team of expert technicians uses state-of-the-art equipment to provide accurate and reliable results

Customized Testing Programs We work with you to develop customized testing programs that meet your unique requirements and industry standards.

Rapid Turnaround Times Our efficient testing protocols ensure prompt delivery of results, allowing you to schedule maintenance and repairs quickly.

Accurate Results Our team uses advanced testing techniques to provide accurate and reliable results, giving you confidence in the integrity of your electrical systems.

Frequently Asked Questions

Q What types of electrical components can be tested?

A We test a wide range of electrical components, including cables, wires, connectors, switches, circuit breakers, and more.

Q How do I schedule testing for my electrical components?

A Contact us to discuss your specific needs and develop a customized testing program tailored to your business requirements.

Q What is the typical turnaround time for test results?

A Our rapid testing protocols ensure prompt delivery of results, typically within 24-48 hours.

Q Are the results provided in a report format?

A Yes, we provide detailed reports summarizing the test results, including any recommendations for maintenance or repairs.

Q Can I trust the accuracy and reliability of the test results?

A Absolutely. Our team uses state-of-the-art equipment and follows industry-standard testing protocols to ensure accurate and reliable results.

Conclusion

In conclusion, testing the resistance of electrical wiring and components is a crucial aspect of maintaining long-term reliability and efficiency in industrial operations. At Eurolab, we offer a comprehensive range of laboratory services tailored to your specific needs, ensuring that you meet regulatory requirements while minimizing downtime and costs. By partnering with us, you can ensure the integrity of your electrical systems, predict potential issues before they arise, and maintain a reputation for excellence.

Additional Resources

For more information on our laboratory services or to discuss your testing needs, please visit our website at insert URL.

-

Evaluating the electrical safety of consumer products to prevent shock, short circuits, or fires

-

Testing the insulation and grounding of electrical components in household appliances and electronics

-

Verifying the compliance of electrical products with safety standards to prevent electric hazards

-

Simulating electrical faults or failures to assess the risk of electrical shock or fire in consumer products

-

Testing the protection mechanisms in place to ensure safe operation of electrical circuits in devices

-

Assessing the effectiveness of circuit breakers, fuses, or other safety devices in electrical products

-

Simulating accidental electrical surges or power failures to test the resilience of devices

-

Evaluating the safe handling of electrical products, including exposed wires or connections

-

Testing for the durability and safety of electrical connectors, plugs, and sockets used in consumer products

-

Ensuring that products have proper earthing and insulation to protect users from electric shock

-

Verifying that electrical appliances are free from harmful electromagnetic interference (EMI) or electromagnetic fields (EMF)

-

Testing the performance of safety features like thermal fuses or automatic shut-off systems in electrical products

-

Assessing electrical safety in battery-powered consumer goods to ensure they do not overheat or cause fires

-

Testing the integrity of electrical shielding or covers to prevent accidental contact with live parts

-

Verifying that products comply with global electrical safety certifications and standards

-

Assessing the durability of electrical components under conditions such as humidity, heat, or vibration

-

Simulating long-term usage to test the reliability of electrical systems in consumer devices

-

Testing the protection of user interfaces like buttons or screens from electrical risks

-

Evaluating the safety of electrical power supplies used in consumer goods like kitchen appliances or power tools

-

Ensuring that electrical systems in products are adequately tested for shock, fire, and overload protection