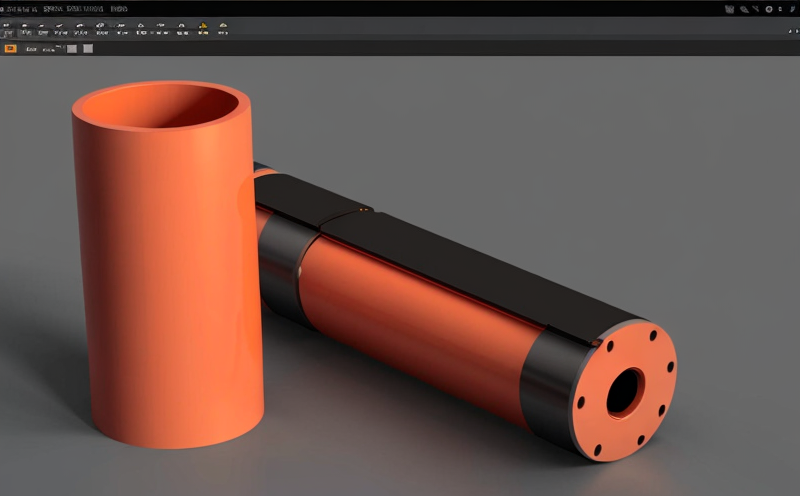

Thermal expansion joint simulation

Unlocking the Secrets of Thermal Expansion Joints Why Eurolabs Simulation Services are a Game-Changer for Your Business

Thermal expansion joints play a crucial role in ensuring the structural integrity and longevity of industrial equipment, bridges, buildings, and pipelines. These critical components allow for the natural movement and contraction of materials due to temperature changes, preventing damage and catastrophic failures. However, predicting the behavior of thermal expansion joints under various conditions can be a daunting task.

This is where Eurolabs Thermal Expansion Joint Simulation services come into play. By leveraging advanced computational models and laboratory testing expertise, we provide you with accurate predictions and insights that ensure your equipment operates safely and efficiently. In this article, we will delve into the world of thermal expansion joint simulation, highlighting its importance, benefits, and how our services can revolutionize your business.

What is Thermal Expansion Joint Simulation?

Thermal expansion joint simulation is a laboratory service that replicates the behavior of thermal expansion joints under various conditions, such as temperature fluctuations, material properties, and load-bearing capacities. This involves creating computational models using software like ANSYS, ABAQUS, or NASTRAN, which are then validated through experimental testing.

Our experts at Eurolab utilize a combination of simulation tools and laboratory equipment to create realistic scenarios that mimic real-world conditions. This allows for the analysis of various factors, including

Material properties (e.g., thermal expansion coefficients, Youngs modulus)

Temperature ranges and gradients

Load-bearing capacities and stresses

Joint configurations and geometries

The Advantages of Thermal Expansion Joint Simulation

Our Thermal Expansion Joint Simulation services offer numerous benefits that can significantly impact your business. Some of the key advantages include

Accurate Predictions and Reduced Risk

By simulating thermal expansion joints, we provide you with accurate predictions of their behavior under various conditions. This enables you to make informed decisions about equipment design, installation, and maintenance, reducing the risk of damage or failure.

Accurately predict thermal expansion joint performance

Identify potential issues before they occur

Reduce downtime and maintenance costs

Cost Savings

Simulating thermal expansion joints allows you to optimize their design and configuration, minimizing material usage and reducing the need for costly repairs or replacements.

Optimize equipment design and configuration

Minimize material usage and waste

Reduce repair and replacement costs

Improved Safety

Thermal Expansion Joint Simulation helps ensure that your equipment operates within safe parameters, preventing accidents and injuries caused by thermal expansion joint failure.

Ensure equipment operates safely and efficiently

Prevent accidents and injuries caused by thermal expansion joint failure

Comply with regulatory requirements

Enhanced Reliability and Performance

By accurately predicting thermal expansion joint behavior, we enable you to design equipment that performs optimally, reducing downtime and improving overall efficiency.

Design equipment for optimal performance

Reduce downtime and maintenance costs

Improve overall reliability and efficiency

How Eurolabs Thermal Expansion Joint Simulation Services Can Benefit Your Business

At Eurolab, our team of experts is dedicated to providing you with the most accurate and reliable thermal expansion joint simulation services. Our comprehensive approach involves

Collaborative Consultation We work closely with your team to understand your specific needs and requirements.

Advanced Computational Modeling Our experienced engineers create complex computational models using industry-leading software.

Laboratory Testing and Validation We conduct thorough laboratory testing to validate the accuracy of our simulations.

Detailed Reporting and Analysis You receive a comprehensive report outlining the results, findings, and recommendations.

Frequently Asked Questions (FAQs)

Q What are the benefits of thermal expansion joint simulation?

A Our services offer accurate predictions, cost savings, improved safety, and enhanced reliability and performance.

Q How does Eurolabs Thermal Expansion Joint Simulation service differ from other laboratory services?

A Our comprehensive approach combines advanced computational modeling with thorough laboratory testing to ensure accuracy and reliability.

Q What software tools do you use for thermal expansion joint simulation?

A We utilize industry-leading software like ANSYS, ABAQUS, or NASTRAN for creating complex computational models.

Q Can I rely on the results of Eurolabs Thermal Expansion Joint Simulation service?

A Absolutely. Our services are backed by a team of experienced engineers and rigorous laboratory testing to ensure accuracy and reliability.

Conclusion

Thermal expansion joint simulation is an essential tool for ensuring the safety, efficiency, and longevity of your equipment. By leveraging Eurolabs expertise in this area, you can reduce risk, save costs, and improve overall performance. Our comprehensive services combine advanced computational modeling with thorough laboratory testing to provide accurate predictions and insights that will revolutionize your business.

Dont wait until its too late contact us today to learn more about our Thermal Expansion Joint Simulation services and how they can benefit your organization.