Thermomechanical analysis protocol

Unlocking Material Properties Why Thermomechanical Analysis Protocol is a Game-Changer for Businesses

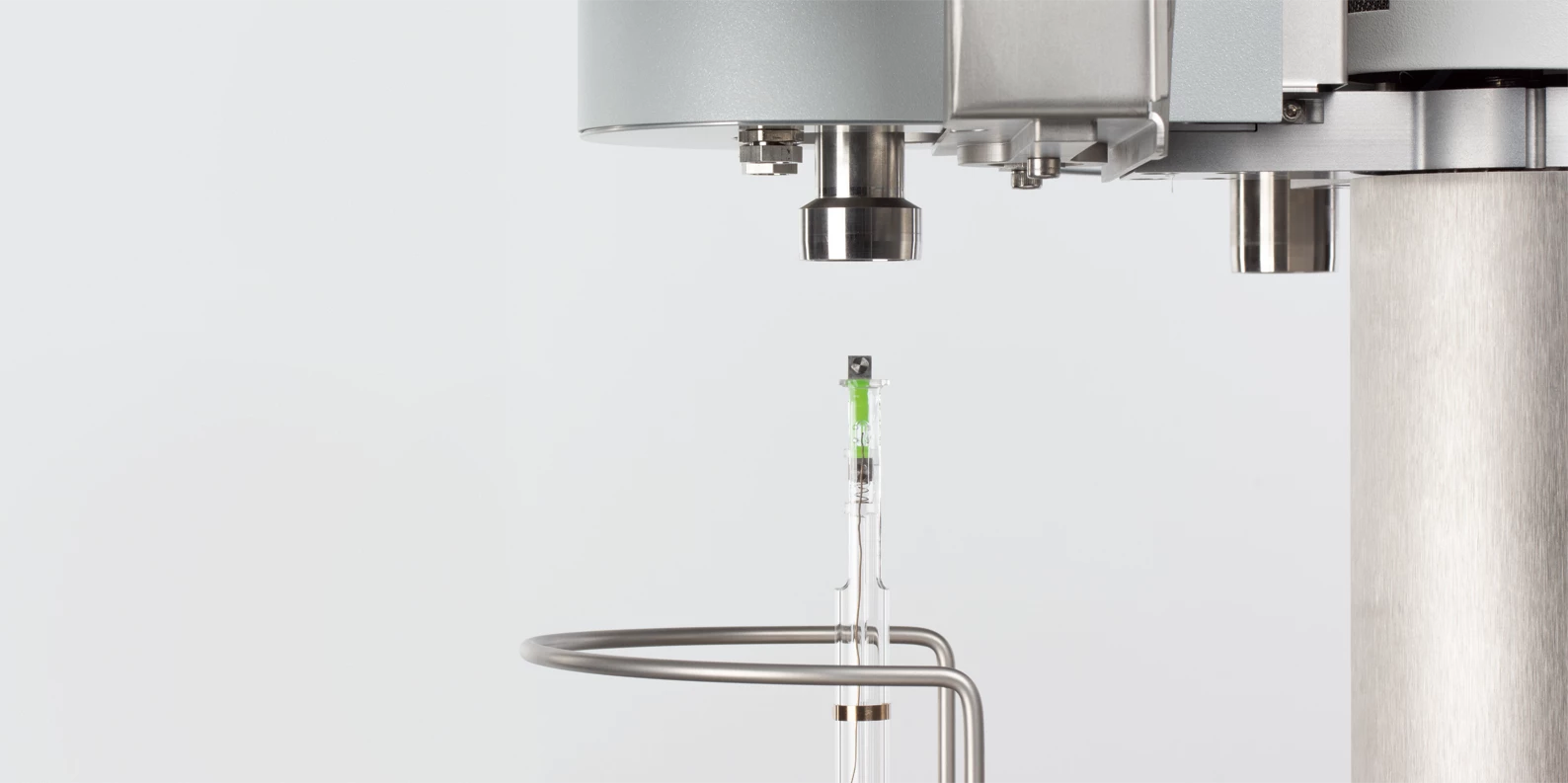

In the world of materials science and engineering, understanding the behavior of materials under various thermal and mechanical conditions is crucial for developing innovative products, improving manufacturing processes, and ensuring product reliability. This is where thermomechanical analysis protocol comes in a sophisticated laboratory service that provides unparalleled insights into material properties.

As a leading provider of scientific services, Eurolabs Thermomechanical Analysis Protocol is designed to help businesses overcome the complexities associated with testing materials under varying thermal and mechanical conditions. By leveraging cutting-edge technology and expert knowledge, our team ensures accurate and reliable results that can be seamlessly integrated into your product development cycle.

In this article, well delve into the world of thermomechanical analysis protocol, exploring its significance, benefits, and applications in various industries. Whether youre a seasoned researcher or an industry newcomer, this comprehensive guide will equip you with the knowledge needed to harness the power of thermomechanical analysis and take your business to the next level.

What is Thermomechanical Analysis Protocol?

Thermomechanical analysis protocol involves subjecting materials to controlled thermal and mechanical conditions to study their response under various scenarios. This technique allows for a comprehensive understanding of material properties, including

Thermal expansion and contraction

Mechanical strength and stiffness

Fatigue behavior

Creep resistance

By analyzing the materials behavior under different temperature regimes, Eurolabs thermomechanical analysis protocol provides valuable insights into its suitability for various applications.

Advantages of Thermomechanical Analysis Protocol

The benefits of thermomechanical analysis protocol are numerous and can be summarized as follows

Improved Material Selection Accurate prediction of material behavior under specific conditions enables informed decision-making during the selection process.

Enhanced Product Reliability Understanding material limitations helps prevent failures, ensuring product reliability and reducing warranty claims.

Optimized Manufacturing Processes Thermomechanical analysis protocol provides insights into optimal processing conditions, streamlining manufacturing processes and minimizing waste.

Increased Innovation By understanding material properties and behavior, researchers can develop innovative products that meet specific performance requirements.

Reduced Development Time With a deeper understanding of material behavior, development cycles are accelerated, allowing businesses to get their products to market faster.

Here are some key benefits in bullet points

Cost Savings Avoiding unnecessary testing and retesting by selecting materials with suitable properties can lead to significant cost savings.

Increased Product Lifespan Understanding material limitations ensures that products are designed for optimal performance, extending lifespan and reducing maintenance costs.

Compliance with Regulations Thermomechanical analysis protocol helps businesses meet regulatory requirements by ensuring that products conform to industry standards.

Improved Quality Control By understanding material behavior, manufacturers can implement effective quality control measures, reducing defects and improving overall product quality.

Applications of Thermomechanical Analysis Protocol

The applications of thermomechanical analysis protocol are diverse and widespread across various industries, including

Aerospace Testing materials for high-temperature applications, such as jet engine components.

Automotive Evaluating material behavior under extreme temperatures and mechanical loads.

Energy Assessing the suitability of materials for energy storage and conversion applications.

Medical Devices Understanding material properties for biomedical implants and devices.

Frequently Asked Questions

Weve compiled a list of frequently asked questions to provide you with additional insights into thermomechanical analysis protocol

Q What are the main differences between thermomechanical analysis and other testing methods?

A Thermomechanical analysis is unique in its ability to study material behavior under controlled thermal and mechanical conditions, providing a comprehensive understanding of material properties.

Q How does Eurolabs thermomechanical analysis protocol differ from others in the industry?

A Our team employs cutting-edge technology and expert knowledge to ensure accurate and reliable results, setting us apart from competitors.

Q What types of materials can be tested using thermomechanical analysis protocol?

A A wide range of materials, including metals, polymers, ceramics, and composites, can be analyzed using our thermomechanical analysis protocol.

Q How long does the testing process typically take?

A The duration of testing depends on the specific requirements of each project. Our team works closely with clients to ensure that results are delivered in a timely manner.

Q Can you provide any case studies or examples of successful projects?

A Yes, wed be happy to share success stories and testimonials from satisfied clients who have benefited from our thermomechanical analysis protocol services.

Conclusion

Thermomechanical analysis protocol is an essential tool for businesses seeking to improve material selection, product reliability, manufacturing processes, and innovation. By leveraging Eurolabs expertise and cutting-edge technology, you can unlock the full potential of your materials and take your business to new heights.

Whether youre a researcher, engineer, or entrepreneur, our thermomechanical analysis protocol services are designed to provide actionable insights that drive product development, improvement, and success. Contact us today to learn more about how Eurolabs Thermomechanical Analysis Protocol can transform your business.