Visual inspection techniques in weld quality testing

The Power of Visual Inspection Ensuring Weld Quality with Eurolabs Expertise

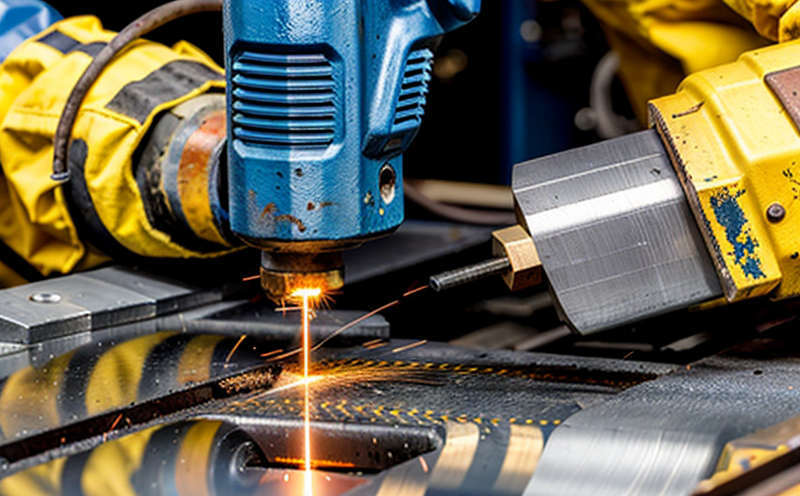

In the world of manufacturing and construction, weld quality is a top priority. A single defect in a weld can compromise the entire structure, putting people and property at risk. Thats why visual inspection techniques in weld quality testing are essential for businesses that demand precision and reliability.

At Eurolab, we understand the importance of thorough weld quality testing. Our laboratory service uses advanced visual inspection techniques to ensure that your welds meet the highest standards. With our expertise, you can trust that your products will be safe, durable, and compliant with regulations.

What is Visual Inspection in Weld Quality Testing?

Visual inspection is a non-destructive testing method that involves examining the weld joint under magnification or illumination. This technique allows our experienced technicians to identify defects, such as lack of fusion, porosity, or cracks, without causing any damage to the material.

Visual inspection is an essential step in weld quality testing because it enables us to detect potential issues before they become major problems. Our state-of-the-art equipment and trained personnel ensure that every weld is scrutinized with utmost care, guaranteeing that your products meet even the most stringent requirements.

Advantages of Visual Inspection Techniques

The benefits of using visual inspection techniques in weld quality testing are numerous

Early Defect Detection Visual inspection allows us to identify defects at an early stage, preventing costly rework or replacements.

Improved Safety By detecting potential issues before they become major problems, we help ensure that your products meet safety standards and regulations.

Enhanced Quality Control Our visual inspection techniques enable us to monitor weld quality consistently, maintaining high standards throughout the manufacturing process.

Reduced Rework Costs Early detection of defects saves time and resources by reducing the need for costly rework or replacements.

Increased Efficiency By identifying potential issues quickly, we help streamline your production schedule, ensuring that projects are completed on time.

Key Benefits in Bullet Points

Compliance with Regulations Our visual inspection techniques ensure that your products meet regulatory requirements, reducing the risk of non-compliance and associated penalties.

Improved Customer Satisfaction With our expertise, you can trust that your products will be safe and reliable, leading to increased customer satisfaction and loyalty.

Reduced Liability By detecting potential issues early, we help minimize liability risks associated with defective welds.

Increased Productivity Our visual inspection techniques enable us to identify areas for improvement, optimizing the manufacturing process and increasing productivity.

Frequently Asked Questions (FAQs)

Q What types of materials can Eurolab inspect?

A We inspect a wide range of materials, including metals, alloys, and composites.

Q How do you ensure accurate results?

A Our experienced technicians use state-of-the-art equipment and follow strict quality control protocols to guarantee accurate results.

Q Can I request specific types of visual inspections?

A Yes, we offer customized services tailored to your specific needs. Please contact us to discuss your requirements.

Q What is the typical turnaround time for visual inspection reports?

A Our standard turnaround time is 24-48 hours, depending on the complexity of the inspection and any additional testing required.

Q Can I rely on Eurolabs expertise for critical welds?

A Absolutely. Our technicians have extensive experience in welding quality control and are well-equipped to handle even the most demanding projects.

Why Choose Eurolab for Visual Inspection Services?

At Eurolab, we pride ourselves on providing comprehensive laboratory services that cater to the specific needs of our clients. With a team of highly trained professionals and state-of-the-art equipment, we offer

Unparalleled Expertise Our technicians are experienced in welding quality control and possess an in-depth understanding of materials science.

Cutting-Edge Technology We invest heavily in the latest inspection equipment to ensure accurate and efficient results.

Comprehensive Services From visual inspection to non-destructive testing, we provide a wide range of laboratory services tailored to your needs.

Dont compromise on weld quality. Trust Eurolabs expertise for all your visual inspection needs. Contact us today to learn more about our comprehensive laboratory services and how we can help ensure that your products meet the highest standards.