Weld quality testing for aerospace components

The Crucial Role of Weld Quality Testing in Aerospace Component Manufacturing Ensuring Safety and Reliability with Eurolabs Expertise

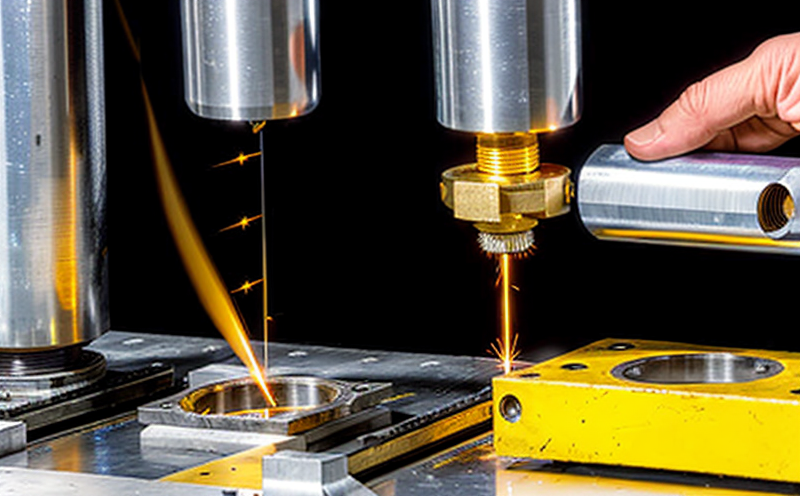

In the aerospace industry, where safety is paramount and reliability is a non-negotiable requirement, manufacturers must adhere to the highest standards of quality control. One critical aspect of this process is weld quality testing for aerospace components. This specialized laboratory service ensures that welding processes meet or exceed stringent specifications, guaranteeing the integrity and reliability of complex structures and systems.

At Eurolab, we understand the gravity of this responsibility and have developed a comprehensive Weld Quality Testing program tailored to the unique needs of aerospace component manufacturers. Our state-of-the-art facilities and team of experienced experts provide unparalleled support in ensuring the highest level of quality control for every weld process.

The Importance of Weld Quality Testing for Aerospace Components

Welding is a critical manufacturing process in the production of aerospace components, as it allows for the joining of dissimilar materials with precision and accuracy. However, welding can also be a potential source of defects, such as porosity, cracking, or inadequate penetration. If not detected early on, these defects can compromise the structural integrity and safety of an aircraft.

To mitigate this risk, aerospace manufacturers rely heavily on weld quality testing to ensure that their products meet or exceed industry standards. This includes

Federal Aviation Administration (FAA) regulations for commercial and general aviation aircraft

International Civil Aviation Organization (ICAO) requirements for international air travel

Industry-specific guidelines, such as those established by the Society of Automotive Engineers (SAE) and the American Society for Testing and Materials (ASTM)

Advantages of Weld Quality Testing with Eurolab

Our comprehensive Weld Quality Testing program offers numerous benefits to aerospace component manufacturers, including

Enhanced Safety By identifying potential defects early on, we enable manufacturers to take corrective action, ensuring that their products meet or exceed safety standards.

Improved Reliability Our testing procedures ensure that welds are structurally sound and reliable, minimizing the risk of in-service failures.

Compliance with Regulations We help manufacturers stay compliant with industry-specific guidelines and regulations, reducing the risk of costly rework or recalls.

Increased Efficiency By identifying defects early on, we enable manufacturers to streamline their production process, reducing downtime and increasing overall productivity.

Cost Savings Early detection of defects can prevent costly repairs, replacements, or redesigns down the line.

How Our Weld Quality Testing Services Can Help You

Our expert team at Eurolab offers a wide range of services designed to meet the unique needs of aerospace component manufacturers. These include

Mechanical Testing We conduct thorough mechanical testing to ensure that welds meet or exceed industry standards for strength, durability, and toughness.

Non-Destructive Testing (NDT) Our NDT services use advanced techniques such as radiography, ultrasonic inspection, and visual inspection to detect potential defects without damaging the material.

Metallurgical Analysis We provide comprehensive metallurgical analysis to identify any issues with weld metal composition, structure, or properties.

Specialized Testing Our team is equipped to perform specialized testing procedures tailored to specific aerospace applications.

Frequently Asked Questions (FAQs)

What types of aerospace components do you test?

At Eurolab, we specialize in testing a wide range of aerospace components, including aircraft structures, engine components, and satellite parts.

How long does the testing process typically take?

Our testing procedures are designed to be efficient and flexible, with turnaround times ranging from a few days to several weeks, depending on the complexity of the test.

What types of defects can you detect through weld quality testing?

We can detect a variety of defects, including porosity, cracking, inadequate penetration, and metallurgical issues.

How do I prepare my components for testing?

Please follow our standard preparation guidelines, which include cleaning and packaging the components according to industry-specific standards.

Can you provide certified reports and certifications?

Yes, we issue comprehensive, certified reports that meet or exceed regulatory requirements.

Why Choose Eurolab for Your Weld Quality Testing Needs

At Eurolab, were committed to delivering exceptional service, quality, and expertise to our clients in the aerospace industry. Our team is dedicated to helping you

Meet or Exceed Industry Standards We ensure that your products meet or exceed regulatory requirements.

Maintain High Productivity By identifying potential defects early on, we enable manufacturers to streamline their production process.

Ensure Safety and Reliability Our comprehensive testing procedures guarantee the structural integrity of your aerospace components.

When it comes to weld quality testing for aerospace components, trust only the experts. Choose Eurolab for peace of mind, knowing that your products are held to the highest standards of safety and reliability. Contact us today to learn more about our services and how we can support your business needs.