Adhesion strength testing for industrial coatings

Adhesion Strength Testing for Industrial Coatings Ensuring Your Assets Last Longer

In the world of industrial coatings, a seemingly small issue can have significant consequences. One such problem is poor adhesion between the coating and the substrate its applied to. When this occurs, it can lead to premature failure, decreased product lifespan, and costly repairs or replacements.

At Eurolab, we understand the importance of ensuring the integrity of your industrial coatings. Our Adhesion Strength Testing service provides a critical evaluation of the bond between your coating and its substrate. This laboratory testing helps businesses identify potential issues before they become major problems, reducing downtime, and saving you money in the long run.

The Importance of Adhesion Strength Testing for Industrial Coatings

Adhesion strength testing is not just an optional step; its a necessary part of ensuring the reliability and durability of your coatings. Here are some key reasons why

Safety Poor adhesion can lead to coating failure, causing damage or harm to people, equipment, and the environment.

Product Performance Inadequate bonding can compromise the functionality and effectiveness of your industrial coatings.

Cost Savings Identifying issues early on prevents costly repairs, replacements, and potential legal liabilities.

Compliance Regulatory bodies often require adhesion testing for coatings used in specific industries or applications.

Key Benefits of Adhesion Strength Testing for Industrial Coatings

Our Adhesion Strength Testing service offers numerous benefits to businesses

Early Issue Detection Identify potential problems before they cause damage or downtime.

Reduced Maintenance Costs Prevent costly repairs and replacements by addressing issues early on.

Increased Product Lifespan Ensure your coatings perform as intended, reducing the need for premature replacements.

Enhanced Safety Minimize the risk of coating failure and associated hazards.

Compliance with Regulations Meet industry-specific requirements and avoid potential legal liabilities.

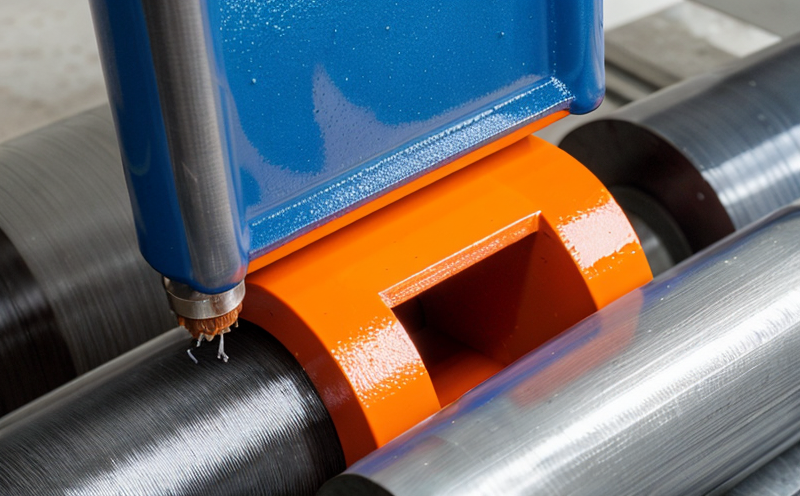

Our Adhesion Strength Testing Process

At Eurolab, we use state-of-the-art equipment and techniques to provide accurate and reliable adhesion strength testing results. Our process involves

Sample Preparation Carefully prepare the samples to be tested, ensuring they are representative of your industrial coatings.

Adhesion Testing Utilize industry-standard methods, such as ASTM D4541 or ISO 4624, to evaluate the bond between the coating and substrate.

Data Analysis Provide detailed reports highlighting adhesion strength values, along with recommendations for improvement.

Frequently Asked Questions

Weve compiled a list of common questions about Adhesion Strength Testing to help you better understand our service

Q What types of coatings can be tested?

A We test various industrial coatings, including paints, primers, sealants, and linings.

Q What is the minimum sample size required for testing?

A Our standard sample size is 25mm x 25mm; however, we can accommodate smaller samples with prior arrangement.

Q How long does it take to receive test results?

A Results are typically available within 3-5 business days, depending on the scope of testing and workload.

Conclusion

Adhesion strength testing for industrial coatings is a critical step in ensuring your assets last longer. By identifying potential issues early on, you can prevent costly repairs, replacements, and potential legal liabilities. At Eurolab, our expert team provides accurate and reliable results using state-of-the-art equipment and techniques. Contact us today to schedule your Adhesion Strength Testing service and protect your business from the risks associated with poor coating adhesion.

Learn More

To discover more about our Adhesion Strength Testing service or to discuss your specific testing needs, visit our website at www.eurolab.com(http//www.eurolab.com).