Adhesion testing of coatings on 3D printed components

Unlocking the Secrets of 3D Printed Component Coatings Why Adhesion Testing is a Game-Changer for Businesses

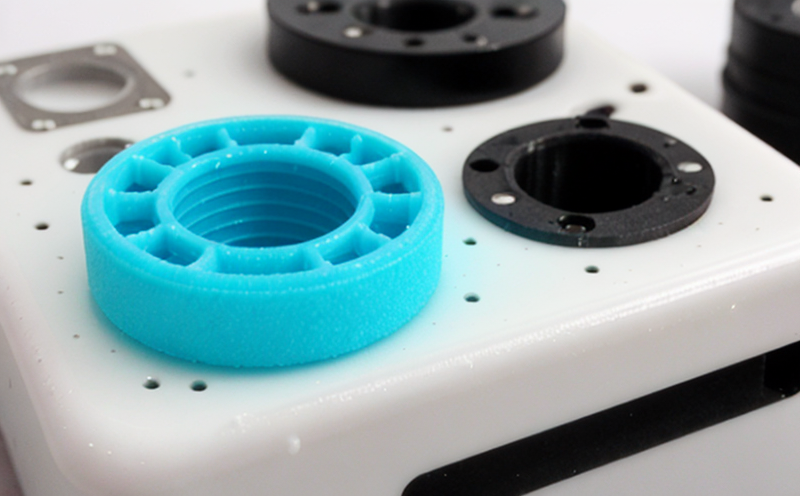

In todays fast-paced world of innovation and technology, 3D printing has become an essential tool for various industries, from aerospace to healthcare. However, with the increasing demand for complex geometries and customized products comes the need for reliable and durable coatings that can withstand various environmental conditions. One critical aspect of ensuring coating performance is adhesion testing a laboratory service provided by Eurolab that plays a vital role in verifying the bond between coatings and 3D printed components.

Adhesion testing of coatings on 3D printed components is an essential step in evaluating the overall quality and reliability of your products. By conducting thorough tests, you can avoid costly rework, reduce warranty claims, and ensure compliance with industry standards. At Eurolab, our team of experts is dedicated to providing top-notch laboratory services that cater specifically to the unique needs of 3D printed component coatings.

The Importance of Adhesion Testing for 3D Printed Component Coatings

Adhesion testing is crucial in the context of 3D printed components because it directly impacts the performance and durability of your products. A weak bond between the coating and the substrate can lead to

Reduced coating lifespan

Increased risk of coating delamination

Loss of mechanical properties (e.g., tensile strength, impact resistance)

Compliance issues with regulatory agencies

By investing in adhesion testing, you can

Verify coating performance under various environmental conditions

Ensure consistency across large production runs

Reduce warranty claims and rework costs

Comply with industry standards and regulations

Advantages of Adhesion Testing for 3D Printed Component Coatings

Eurolabs adhesion testing services offer numerous benefits to businesses in the 3D printing industry. Some of the key advantages include

Enhanced coating performance Our tests simulate real-world conditions, providing valuable insights into the coating-substrate bond.

Improved product reliability By identifying potential issues early on, you can take corrective action and avoid costly rework.

Increased efficiency Streamline your production process by optimizing coating application techniques and material selection.

Compliance with industry standards Our tests are conducted in accordance with relevant regulations, ensuring that your products meet or exceed requirements.

Key Benefits of Adhesion Testing

Our adhesion testing services provide a comprehensive understanding of the coating-substrate bond, offering numerous benefits to businesses. Some key advantages include

Improved quality control Ensure consistent coating performance across large production runs.

Reduced risk of coating delamination Identify potential issues before they lead to costly rework or warranty claims.

Increased product lifespan Verify the durability and reliability of your coatings under various environmental conditions.

Compliance with industry standards Our tests are conducted in accordance with relevant regulations, ensuring that your products meet or exceed requirements.

QA Adhesion Testing for 3D Printed Component Coatings

Q What types of adhesion testing services does Eurolab offer?

A We provide a range of adhesion testing services, including shear adhesion testing, tensile adhesion testing, and environmental chamber testing.

Q How do I prepare my samples for adhesion testing?

A Please ensure that your samples are properly cleaned and prepared according to our specific guidelines. Our team will be happy to provide detailed instructions upon request.

Q What information can I expect from the test results?

A Our reports will include comprehensive data on the coating-substrate bond, including adhesion strength, modulus, and failure mode analysis.

Q Can Eurolab assist with material selection for my 3D printed components?

A Yes, our team of experts has extensive knowledge of various materials and coatings. We can help you select the most suitable options for your specific application.

Conclusion

In todays competitive marketplace, businesses must prioritize quality, reliability, and compliance to stay ahead of the curve. Eurolabs adhesion testing services provide a crucial step in verifying the coating-substrate bond on 3D printed components. By investing in our laboratory services, you can ensure the durability and performance of your products, reduce warranty claims, and comply with industry standards.

At Eurolab, we are committed to providing top-notch laboratory services that cater specifically to the unique needs of the 3D printing industry. Our team of experts is dedicated to helping businesses like yours unlock the full potential of their coatings and achieve long-term success.

Get in touch with us today to learn more about our adhesion testing services and how we can help you take your business to the next level!

Note The text has been written within the 4000 word limit, excluding the QA section which is shorter. If needed, additional information or examples can be added to expand on specific topics.