Crosshatch adhesion testing for thin films

The Importance of Crosshatch Adhesion Testing for Thin Films Enhance Your Products Performance and Reliability

In the world of thin-film technology, ensuring the adhesion between layers is crucial to prevent failures and guarantee product performance. Crosshatch adhesion testing for thin films is a laboratory service that plays a vital role in assessing the bond strength between various materials. Eurolab offers this essential testing service to help businesses like yours ensure the reliability and longevity of your products.

What is Crosshatch Adhesion Testing for Thin Films?

Crosshatch adhesion testing, also known as the cross-cut or cross-hatch test, is a widely accepted method used to evaluate the bond strength between thin films and substrates. This non-destructive testing technique involves applying parallel scratches on the surface of the film in a grid-like pattern. The resulting scratches then create multiple sites for peel-off, which allows for an assessment of the adhesion properties.

Why Choose Crosshatch Adhesion Testing for Thin Films?

Incorporating crosshatch adhesion testing into your quality control process offers numerous advantages that can significantly impact your businesss success

Ensures Reliability and Longevity By verifying the bond strength between thin films, you can prevent unexpected failures and ensure your products perform consistently over time.

Improves Product Performance Strong adhesion is essential for maintaining electrical properties, preventing degradation, and ensuring the overall quality of your products.

Minimizes Scratches and Damage Crosshatch adhesion testing helps identify potential issues before they lead to costly repairs or replacements.

Enhances Manufacturing Efficiency By optimizing production processes, you can reduce waste, lower costs, and meet increasing demand.

Key Benefits of Using Crosshatch Adhesion Testing for Thin Films

Crosshatch adhesion testing offers numerous benefits that cater to the specific needs of thin-film manufacturers. Some of the most significant advantages include

High Accuracy The crosshatch pattern provides multiple sites for peel-off, ensuring accurate and reliable results.

Non-Destructive Nature This technique allows you to test samples without causing damage or compromising their integrity.

Flexibility Crosshatch adhesion testing can be performed on a wide range of materials and film types, making it an adaptable solution for various industries.

Frequently Asked Questions (FAQs)

Weve compiled a comprehensive list of frequently asked questions about crosshatch adhesion testing to provide you with more information

What is the standard size of the samples required for crosshatch adhesion testing?

The sample size may vary depending on the specific requirements and equipment used. Typically, samples are around 25mm x 50mm in size.

How long does it take to conduct a crosshatch adhesion test?

The duration of the test can range from 30 minutes to several hours, depending on the complexity of the test and the number of samples being evaluated.

Can I perform crosshatch adhesion testing in-house or should I outsource to Eurolab?

While it is technically possible to conduct crosshatch adhesion testing in-house, outsourcing to a specialized laboratory like Eurolab ensures high-quality results, precise calibration, and compliance with industry standards.

Will the crosshatch pattern damage my product?

The crosshatch pattern does not cause lasting damage to your products. The scratches are temporary and do not compromise the integrity of the thin film.

How can I use the results from a crosshatch adhesion test?

The data obtained from the crosshatch adhesion test will help you identify areas for improvement, optimize manufacturing processes, and ensure the quality and performance of your products.

Why Choose Eurolab for Your Crosshatch Adhesion Testing Needs?

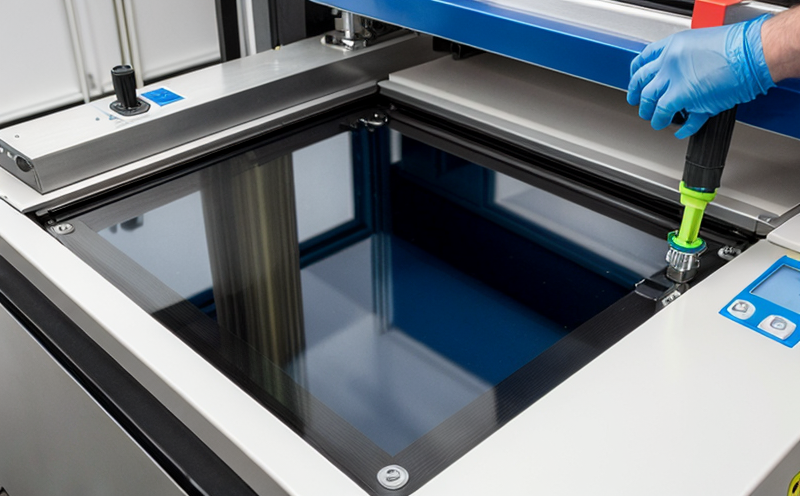

At Eurolab, we understand the importance of precise testing results in maintaining product reliability and performance. Our team of experienced experts ensures accurate and reliable crosshatch adhesion testing using state-of-the-art equipment and following industry-recognized standards.

By partnering with us, you can trust that your products are being tested by a trusted authority in the field of thin-film technology. Dont compromise on quality; choose Eurolab for all your laboratory needs.

Conclusion

Crosshatch adhesion testing for thin films is an essential step in ensuring the reliability and performance of your products. By incorporating this service into your quality control process, you can enhance manufacturing efficiency, minimize scratches and damage, and improve product longevity. At Eurolab, were committed to providing precise and reliable results that will help drive your business forward. Contact us today to learn more about our laboratory services and how we can support your success.