Assessing the pressure resistance of medical device seals and closures

Assessing the Pressure Resistance of Medical Device Seals and Closures A Crucial Laboratory Service for Businesses

In the highly regulated medical device industry, ensuring the safety and efficacy of products is paramount. One critical aspect of product development and testing is assessing the pressure resistance of medical device seals and closures. This laboratory service, offered by Eurolab, helps businesses validate their products performance under various conditions, reducing the risk of product failure and minimizing regulatory hurdles.

What is Assessing the Pressure Resistance of Medical Device Seals and Closures?

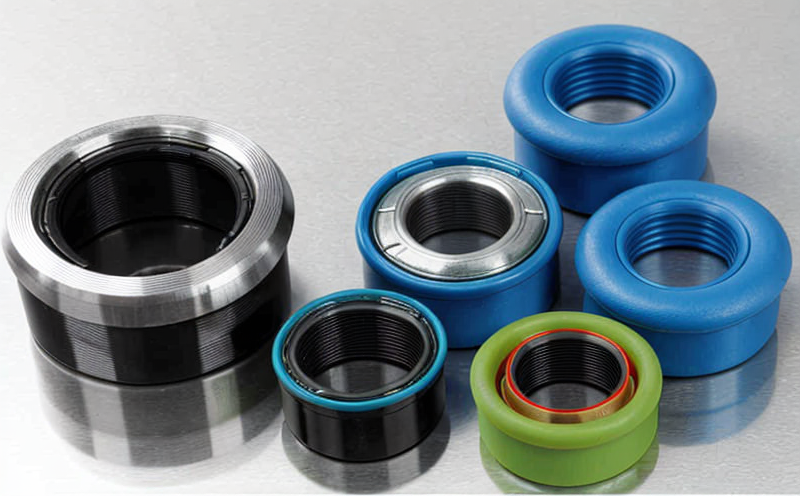

Assessing the pressure resistance of medical device seals and closures involves subjecting samples to controlled pressures to evaluate their ability to maintain a tight seal and withstand external forces. This process simulates real-world conditions, such as those encountered during transportation, storage, or use in healthcare settings.

In medical devices, seals and closures play a vital role in ensuring the sterility and integrity of the product. Failure to meet pressure resistance requirements can compromise device performance, lead to patient harm, or even result in costly product recalls.

Why is Assessing the Pressure Resistance of Medical Device Seals and Closures Essential for Businesses?

Eurolabs laboratory service offers numerous advantages that benefit businesses in the medical device industry

Ensures Compliance with Regulations Regulatory bodies, such as the FDA (US) and ISO (International Organization), mandate testing to ensure devices meet specific requirements. Our services help companies comply with these regulations, reducing the risk of non-compliance and associated penalties.

Minimizes Product Failure By evaluating pressure resistance, businesses can identify potential issues early on, preventing costly product recalls and reputational damage.

Enhances Product Safety Medical devices must be designed to maintain a tight seal and withstand external forces. Our laboratory service ensures that products meet safety standards, reducing the risk of patient harm or injury.

Optimizes Design and Development By understanding how seals and closures perform under pressure, businesses can refine their product design, improving overall performance and user experience.

Key Benefits of Eurolabs Laboratory Service

Eurolabs Assessing the Pressure Resistance of Medical Device Seals and Closures laboratory service offers numerous benefits

Comprehensive Testing Our expert team conducts a range of tests to evaluate pressure resistance under various conditions, including temperature extremes.

State-of-the-Art Equipment We utilize cutting-edge equipment to simulate real-world pressures and temperatures, ensuring accurate results.

Rapid Turnaround Times Eurolabs experienced staff ensures prompt testing and reporting, minimizing delays in product development and launch.

Expert Interpretation of Results Our team provides detailed analysis and recommendations for improving product design and performance.

QA Frequently Asked Questions About Assessing the Pressure Resistance of Medical Device Seals and Closures

Q What types of medical devices require pressure resistance testing?

A Any device with seals or closures, such as syringes, IV sets, catheters, and implantable devices.

Q Why is temperature also a factor in pressure resistance testing?

A Temperature affects the materials performance and properties. Testing under various temperatures ensures products meet requirements across different usage scenarios.

Q Can Eurolab accommodate large-volume testing for production lots?

A Yes, our laboratory service is designed to handle high-volume testing for production batches, ensuring efficient processing and timely results.

Q Are the test results validated by regulatory bodies?

A Eurolabs testing protocols adhere to industry standards and guidelines. Results can be used to support regulatory submissions, demonstrating compliance with applicable regulations.

By utilizing Eurolabs Assessing the Pressure Resistance of Medical Device Seals and Closures laboratory service, businesses in the medical device industry can ensure their products meet safety and efficacy requirements, reducing the risk of product failure, regulatory hurdles, and reputational damage.