Testing for durability of pressurized medical devices over time

Testing for Durability of Pressurized Medical Devices Over Time A Crucial Laboratory Service

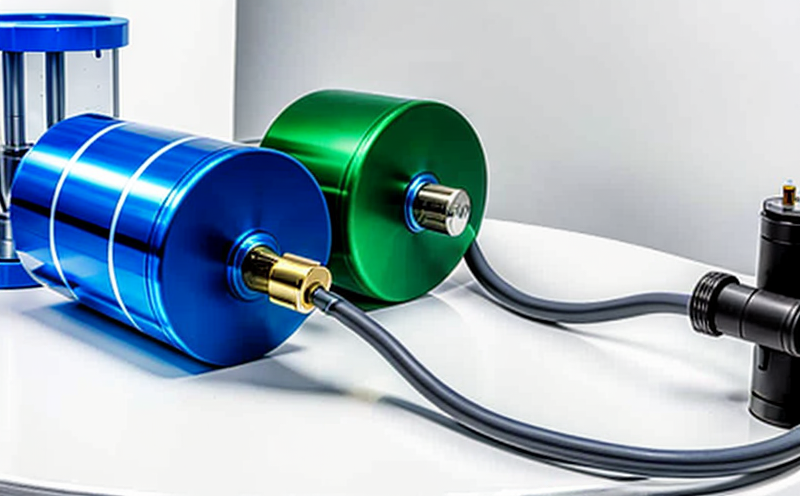

In the medical device industry, safety and efficacy are paramount. One critical aspect that manufacturers must consider is the durability of pressurized medical devices over time. These devices, including ventilators, respirators, anesthesia machines, and infusion pumps, require rigorous testing to ensure they can withstand the rigors of repeated use, storage, and transportation without compromising patient care.

At Eurolab, we specialize in providing a comprehensive laboratory service that simulates real-world conditions to assess the durability of pressurized medical devices. Our expertise lies in subjecting these critical equipment to controlled environments, replicating various stress factors, and analyzing their performance over extended periods. This meticulous testing not only enhances the reliability and safety of your products but also boosts your brands credibility.

What is Testing for Durability of Pressurized Medical Devices Over Time?

Durability testing involves subjecting pressurized medical devices to simulated use conditions, including thermal variations, vibration, humidity, and pressure fluctuations. Our laboratory service replicates the stresses that these devices would experience during shipping, storage, maintenance, and actual clinical use.

Advantages of Using Eurolabs Testing Service

Our expertise and state-of-the-art facilities ensure that your pressurized medical devices are rigorously tested for

Increased Reliability By identifying potential weaknesses in your products design or materials, we help you develop more robust equipment that can withstand various operational demands.

Enhanced Patient Safety Our testing ensures that your medical devices continue to function correctly over time, reducing the risk of device failure and associated patient harm.

Reduced Maintenance Costs By identifying wear-and-tear issues early on, we help you develop maintenance schedules that minimize downtime and reduce overall expenses.

Key Benefits

Compliance with Regulatory Standards Our testing adheres to international standards (e.g., IEC 60601-1) and ensures your products meet regulatory requirements.

Improved Product Design By simulating real-world conditions, we help you identify design flaws and optimize your products performance.

Increased Competitiveness Demonstrating the durability of your pressurized medical devices can give your business a competitive edge in the market.

QA Section

What types of testing do you offer?

We provide a comprehensive range of tests, including

Thermal shock and temperature cycling

Vibration testing (shaker or sine)

Humidity testing (constant or cyclic)

Pressure testing (static or dynamic)

How do I prepare my pressurized medical devices for testing?

Please ensure that your products are packaged according to the manufacturers instructions, with all relevant documentation included. You should also provide us with detailed specifications and requirements for each test.

What kind of reporting and certification will I receive after testing?

We provide a comprehensive report detailing our findings, including any issues identified during testing. Our reports adhere to industry standards and are suitable for regulatory submission purposes.

Conclusion

At Eurolab, we understand the importance of ensuring your pressurized medical devices durability over time. By partnering with us, you can rest assured that your products meet the highest safety and performance standards, giving you peace of mind and confidence in your brands reputation. Let us help you take your business to the next level by choosing our laboratory service for testing.