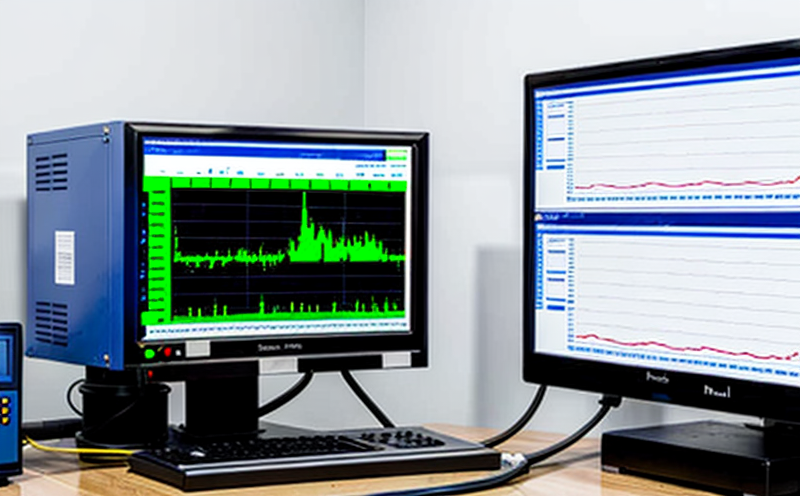

Real-time monitoring of pressure resistance during testing

The Power of Real-time Monitoring Why Your Business Needs It

In todays fast-paced and competitive business landscape, staying ahead of the curve is crucial for success. One key area where companies often struggle to keep up is in ensuring the integrity and reliability of their products. A critical aspect of this process is testing pressure resistance during manufacturing or product development. At Eurolab, we understand the importance of real-time monitoring of pressure resistance during testing, a laboratory service that sets us apart as industry leaders.

Real-time monitoring of pressure resistance during testing involves using advanced technologies to continuously monitor and record the pressure resistance of products under various conditions. This service is essential for businesses looking to ensure their products meet regulatory requirements, are safe for use, and maintain their integrity over time. In this article, well delve into the benefits of real-time monitoring of pressure resistance during testing, discuss its importance in product development, and answer frequently asked questions.

The Benefits of Real-time Monitoring of Pressure Resistance During Testing

Our service offers numerous advantages that can significantly impact your businesss bottom line and reputation. Here are just a few key benefits

Improved Product Safety and Reliability

Ensures products meet regulatory requirements

Reduces risk of product failure or recall

Enhances customer trust and loyalty

By continuously monitoring pressure resistance, you can be confident that your products will withstand various conditions without compromising safety or performance.

Enhanced Quality Control

Detects defects and anomalies early on

Optimizes production processes for better efficiency

Reduces waste and saves resources

Real-time monitoring helps identify potential issues before they cause significant problems, allowing you to make informed decisions about product quality and manufacturing processes.

Increased Efficiency and Cost Savings

Accelerates testing cycles with rapid data collection

Enables data-driven decision making

Reduces testing costs through reduced iterations and rework

By leveraging real-time monitoring, you can streamline your testing process, reducing the time and resources required to ensure product compliance and quality.

Competitive Advantage

Differentiates your products in a crowded market

Demonstrates commitment to excellence and customer safety

Enhances brand reputation and trustworthiness

Investing in real-time monitoring of pressure resistance during testing sets your business apart from competitors, showcasing your dedication to producing high-quality, reliable products.

Reduced Risk and Liability

Mitigates risk of product liability claims

Protects against costly recalls and rework

Ensures compliance with regulatory requirements

By ensuring the integrity and safety of your products through real-time monitoring, you can minimize potential risks and liabilities associated with faulty or non-compliant goods.

Informed Decision Making

Empowers data-driven decision making

Supports strategic planning and product development

Fosters a culture of continuous improvement

Real-time monitoring provides actionable insights that enable informed decisions about product design, manufacturing processes, and quality control measures.

Frequently Asked Questions (FAQs)

What types of products can benefit from real-time monitoring of pressure resistance during testing?

Our service is suitable for various industries, including aerospace, automotive, medical devices, packaging, and more. We work with a wide range of products, such as pipes, valves, containers, and machinery components.

How does real-time monitoring differ from traditional testing methods?

Traditional testing often involves collecting data at fixed intervals or after completion of the test cycle. Real-time monitoring, on the other hand, continuously collects and records pressure resistance data throughout the test process, providing a more comprehensive understanding of product performance.

What technology is used for real-time monitoring?

We employ advanced technologies, such as sensors, data acquisition systems, and software, to collect and analyze pressure resistance data in real-time.

Can I access the collected data in real-time?

Yes, our system allows you to monitor test results in real-time, enabling you to make informed decisions about product quality and manufacturing processes.

Is real-time monitoring of pressure resistance during testing compliant with regulatory requirements?

Our service is designed to meet or exceed industry standards and regulations, ensuring that your products are safe for use and comply with relevant laws and guidelines.

How can I get started with Eurolabs real-time monitoring service?

To begin the process, simply contact us through our online platform or consult our website for more information on how to initiate a project.

Conclusion

In todays fast-paced business landscape, staying ahead of the curve requires investing in technologies and services that ensure product safety, reliability, and quality. Real-time monitoring of pressure resistance during testing is an essential tool for businesses looking to maintain their competitive edge. By leveraging Eurolabs expertise and cutting-edge technology, you can confidently ensure your products meet regulatory requirements, are safe for use, and maintain their integrity over time. Dont wait get in touch with us today to learn more about how our real-time monitoring service can revolutionize your business.

References

While weve discussed the benefits of real-time monitoring extensively, its essential to note that regulatory requirements may vary depending on industry, location, and product type. For specific information on compliance and testing standards, consult relevant authorities or industry guidelines.

Join us in embracing innovation and excellence with Eurolab your partner for precision laboratory services.