Assessing the tensile properties of pharmaceutical packaging to ensure it meets regulatory standards

The Crucial Role of Assessing Tensile Properties in Pharmaceutical Packaging Ensuring Compliance with Regulatory Standards

In the pharmaceutical industry, packaging is more than just a container for products; its a critical component that plays a vital role in maintaining product integrity and ensuring patient safety. With increasing regulations and stringent quality control measures, assessing the tensile properties of pharmaceutical packaging has become an essential service for businesses to guarantee compliance with regulatory standards.

As a leading laboratory services provider, Eurolab specializes in evaluating the tensile properties of pharmaceutical packaging to ensure it meets or exceeds industry expectations. Our state-of-the-art testing facilities and expert team are equipped to handle a wide range of packaging materials and configurations, providing clients with accurate and reliable results that facilitate informed decision-making.

Why is Assessing Tensile Properties Essential for Pharmaceutical Packaging?

Pharmaceutical packaging undergoes rigorous testing to ensure it can withstand various environmental factors, including temperature fluctuations, humidity, and mechanical stress. The tensile properties of packaging materials determine their ability to resist deformation, cracking, or failure under these conditions. A flawed packaging design or material can compromise the integrity of the product, leading to contamination, leakage, or even device failure.

The consequences of inadequate packaging testing can be severe

Product recalls Failure to meet regulatory standards can lead to costly product recalls and damage to a companys reputation.

Regulatory fines Non-compliance with industry regulations can result in hefty fines and penalties.

Patient safety risks Subpar packaging can compromise the efficacy of medicinal products, putting patients lives at risk.

The Benefits of Using Eurolabs Assessing Tensile Properties Service

Eurolabs expert team and advanced testing facilities offer numerous advantages when it comes to assessing the tensile properties of pharmaceutical packaging. Some key benefits include

Compliance with regulatory standards Our services ensure that your packaging meets or exceeds industry expectations, minimizing the risk of non-compliance and associated fines.

Product safety and efficacy By evaluating the tensile properties of your packaging, we help you identify potential issues before they compromise product integrity.

Cost savings Identifying and addressing packaging flaws early on can prevent costly recalls and product revisions.

Increased efficiency Our streamlined testing process allows for faster turnaround times, enabling you to bring products to market more quickly.

Key Benefits of Eurolabs Assessing Tensile Properties Service

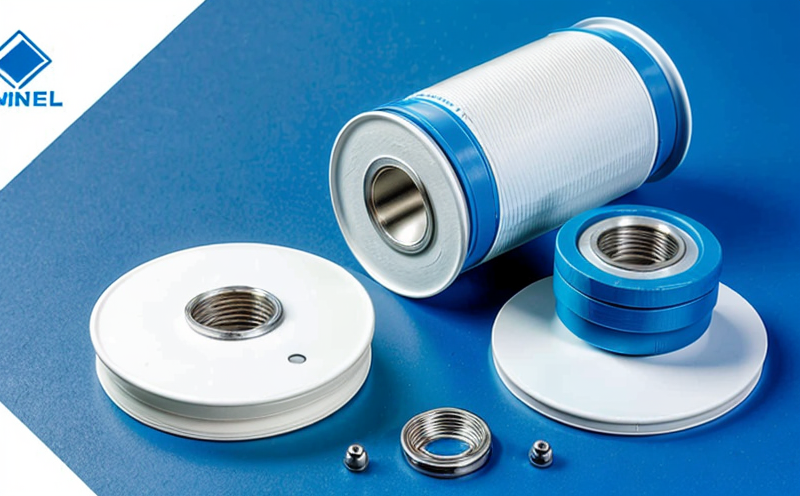

Comprehensive testing capabilities We evaluate the tensile properties of various packaging materials and configurations, including films, bottles, syringes, and blister packs.

Expert interpretation of results Our team provides detailed reports and recommendations to help you optimize your packaging design and material selection.

Accurate and reliable results Our state-of-the-art testing equipment ensures precise measurements and minimizes the risk of human error.

Rapid turnaround times We prioritize expedited testing and reporting, ensuring that you receive timely results to inform product development and launch decisions.

QA Frequently Asked Questions About Assessing Tensile Properties

Q What types of packaging materials can be tested?

A We evaluate a wide range of materials, including plastics, metals, films, and papers.

Q How do I prepare my samples for testing?

A Our team will provide detailed instructions on preparing your samples to ensure accurate and reliable results.

Q Can you test packaging configurations other than single units?

A Yes, we can evaluate packaging configurations such as multi-packs, bundles, or even entire shipping containers.

Q How long does the testing process typically take?

A Our streamlined testing process ensures rapid turnaround times, with most tests completed within 1-3 working days.

Q Can I schedule custom testing programs to meet my specific needs?

A Yes, our team is happy to work with you to develop a customized testing program tailored to your business requirements.

Conclusion

In the competitive pharmaceutical industry, its essential to prioritize packaging integrity and compliance with regulatory standards. Eurolabs assessing tensile properties service provides clients with accurate and reliable results, ensuring that their products meet or exceed industry expectations. By leveraging our expertise and state-of-the-art testing facilities, businesses can mitigate risks associated with non-compliance, product safety, and efficacy.

Dont compromise on packaging quality trust Eurolab to ensure your products are safe for patients and compliant with regulatory standards. Contact us today to learn more about our assessing tensile properties service and take the first step towards a safer, more efficient product development process.