Evaluating the performance of sealants and adhesives used in packaging materials under tensile stress

Evaluating the Performance of Sealants and Adhesives Used in Packaging Materials Under Tensile Stress Why It Matters for Businesses

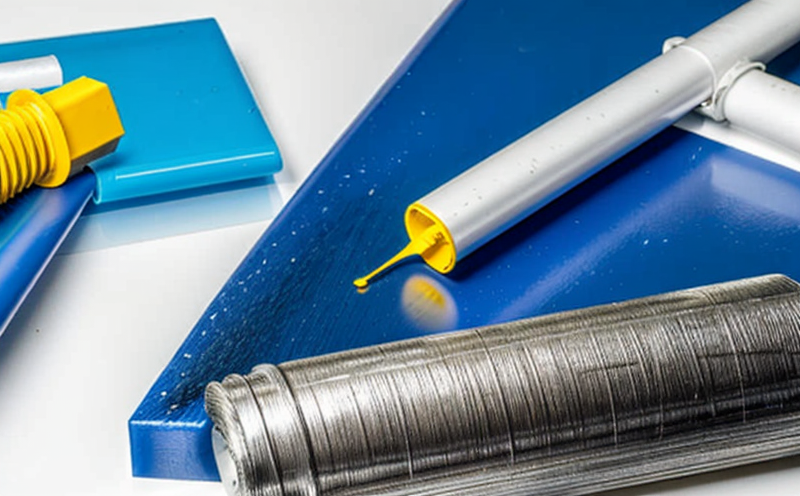

In todays fast-paced packaging industry, the performance of sealants and adhesives used in various applications is a crucial aspect that cannot be overlooked. As products are subjected to diverse environmental conditions, it is essential to assess their ability to withstand tensile stress without compromising on safety, functionality, or aesthetics. This is where Evaluating the Performance of Sealants and Adhesives Used in Packaging Materials Under Tensile Stress comes into play a laboratory service offered by Eurolab that helps businesses ensure their products meet regulatory requirements and consumer expectations.

The Importance of Evaluating Sealant and Adhesive Performance

Packaging materials are exposed to various types of stress, including tensile stress, which can cause them to fail or compromise on product integrity. The consequences of such failures can be severe, leading to damage to reputation, loss of revenue, and even harm to consumers. By evaluating the performance of sealants and adhesives under tensile stress, businesses can

Ensure Compliance with Regulatory Requirements Manufacturers must comply with regulations set by government agencies, industry standards, or international guidelines. Our laboratory service helps ensure that packaging materials meet these requirements.

Maintain Product Integrity Sealant and adhesive performance directly impacts the integrity of packaged products. By evaluating their tensile stress resistance, businesses can guarantee product safety and quality.

Reduce Risk of Product Failure Tensile stress testing identifies potential weaknesses in packaging materials, allowing businesses to make informed decisions about material selection, design modifications, or process improvements.

Improve Brand Reputation Companies that prioritize product quality and safety demonstrate their commitment to customer satisfaction, leading to increased brand loyalty and reputation.

Benefits of Evaluating Sealant and Adhesive Performance Under Tensile Stress

Eurolabs laboratory service provides a comprehensive evaluation of sealants and adhesives under tensile stress, offering numerous benefits to businesses

Accurate Material Selection Our testing helps identify the most suitable materials for specific packaging applications, reducing material waste and minimizing product failures.

Design Optimization By understanding how different sealants and adhesives perform under tensile stress, designers can optimize packaging designs to minimize weaknesses and improve overall performance.

Process Efficiency With a clear understanding of material limitations, businesses can streamline production processes, reduce costs, and enhance quality control.

Regulatory Confidence Our testing provides the data needed to confidently assert compliance with regulatory requirements, reducing the risk of non-compliance and associated penalties.

How Eurolabs Laboratory Service Works

Our Evaluating the Performance of Sealants and Adhesives Used in Packaging Materials Under Tensile Stress service involves a series of rigorous tests designed to simulate real-world conditions. Our expert technicians use state-of-the-art equipment to

Prepare samples according to industry standards or customer specifications.

Apply tensile stress to sealant or adhesive interfaces using advanced machinery.

Monitor and record sample behavior under controlled environmental conditions.

Analyze data to determine material performance, including adhesion strength, elasticity, and failure modes.

QA Frequently Asked Questions

What types of packaging materials can be tested?

Our laboratory service evaluates sealants and adhesives used in various packaging applications, including but not limited to labels, tapes, caps, lids, cartons, pouches, and films.

How long does the testing process take?

The duration of our laboratory service varies depending on test complexity and sample preparation time, typically ranging from 1-5 working days.

What kind of data can I expect to receive from Eurolabs laboratory service?

Our comprehensive reports include detailed analysis of material performance under tensile stress, including adhesion strength, elasticity, failure modes, and recommendations for improvement.

Is the testing process customizable?

Yes, our laboratory service is tailored to meet specific customer requirements, including test methodologies, sample preparation, and data interpretation.

Conclusion

Evaluating the Performance of Sealants and Adhesives Used in Packaging Materials Under Tensile Stress is a critical aspect of product development and packaging optimization. Eurolabs laboratory service offers businesses a reliable means of ensuring their products meet regulatory requirements, maintain product integrity, reduce risk of product failure, and improve brand reputation. By partnering with Eurolab, companies can

Ensure compliance with regulatory requirements

Maintain product integrity

Reduce risk of product failure

Improve brand reputation

Dont let packaging material failures compromise your businesss success. Contact Eurolab today to learn more about our Evaluating the Performance of Sealants and Adhesives Used in Packaging Materials Under Tensile Stress laboratory service and take the first step towards ensuring the quality and safety of your products.