Simulating stress conditions to evaluate the elongation properties of packaging films

Simulating Stress Conditions to Evaluate Elongation Properties of Packaging Films A Crucial Service for Businesses

In todays fast-paced and highly competitive market, packaging plays a vital role in the success of businesses across various industries. From food and beverage to pharmaceuticals and cosmetics, the packaging industry has witnessed significant advancements in recent years, driven by consumer demands for eco-friendly, sustainable, and high-quality products. However, with increased scrutiny on packaging, manufacturers are now required to meet stringent standards, ensuring that their products not only protect their contents but also comply with regulations.

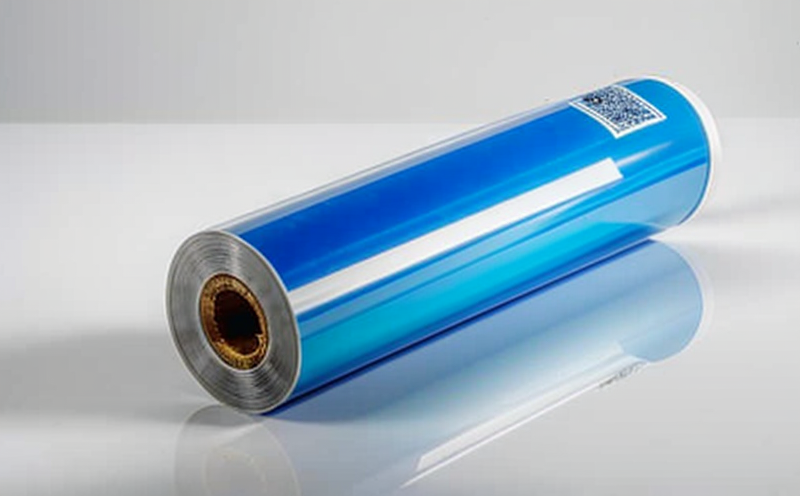

One critical aspect of packaging is its elongation properties, which refer to its ability to stretch or deform without breaking. Simulating stress conditions to evaluate the elongation properties of packaging films has become an essential laboratory service for businesses seeking to guarantee the integrity and quality of their products. In this article, we will delve into the world of simulated stress testing and explore how Eurolabs cutting-edge technology can help businesses like yours meet the ever-growing demands of the market.

What is Simulating Stress Conditions?

Simulating stress conditions involves subjecting packaging films to a controlled environment that mimics real-world scenarios, such as temperature fluctuations, humidity changes, or impact forces. This laboratory service evaluates the elongation properties of packaging materials under various stress conditions, enabling manufacturers to predict their performance in real-life situations.

Why is Simulating Stress Conditions Essential for Businesses?

In todays fast-paced market, businesses must ensure that their products meet stringent standards and regulations. Failure to do so can result in product recalls, damage to brand reputation, and financial losses. By simulating stress conditions, Eurolab helps businesses like yours

Ensure compliance with industry regulations Our laboratory service ensures that your packaging films comply with relevant regulations, such as those set by the FDA or EU guidelines.

Predict real-world performance Our simulated stress testing evaluates the elongation properties of your packaging materials under various conditions, enabling you to predict their behavior in real-life situations.

Reduce product recalls and warranty claims By identifying potential weaknesses in your packaging films, we help you avoid costly product recalls and warranty claims.

Improve brand reputation With Eurolabs expertise, you can guarantee the quality of your products, enhancing your brand reputation and customer trust.

Key Benefits of Simulating Stress Conditions

Here are some key benefits of using Eurolabs simulated stress testing service

Cost savings By identifying potential issues early on, our laboratory service helps you avoid costly product recalls and warranty claims.

Increased efficiency Our expertise ensures that your packaging films meet regulatory requirements, reducing the need for re-testing or re-manufacturing.

Enhanced product performance By evaluating elongation properties under simulated stress conditions, we help you develop high-performance packaging materials.

Compliance with industry regulations Our laboratory service ensures that your products comply with relevant regulations, minimizing the risk of non-compliance.

How Does Eurolabs Simulated Stress Testing Service Work?

Our state-of-the-art laboratory is equipped with cutting-edge technology to simulate various stress conditions, including temperature fluctuations, humidity changes, and impact forces. Heres a step-by-step overview of our simulated stress testing process

Material selection We receive your packaging films for testing.

Pre-testing preparation Our team prepares the samples according to the specified test protocols.

Simulation setup We set up the simulation equipment to mimic real-world scenarios, including temperature and humidity changes or impact forces.

Testing The packaged materials are subjected to simulated stress conditions, and their elongation properties are evaluated.

Data analysis Our expert team analyzes the data collected during testing, providing a comprehensive report on the performance of your packaging films.

QA Your Questions Answered

Weve compiled some frequently asked questions about our simulated stress testing service

What types of packaging materials can be tested?

We test various types of packaging materials, including flexible and rigid plastics, aluminum foils, and paper-based materials.

What are the benefits of simulating stress conditions over traditional testing methods?

Simulated stress testing allows for more accurate predictions of real-world performance, reducing the risk of product recalls and warranty claims.

Can I request customized testing protocols?

Yes, we offer customized testing protocols to meet your specific requirements and industry regulations.

Conclusion

In conclusion, simulating stress conditions to evaluate elongation properties of packaging films is a crucial laboratory service for businesses seeking to ensure the quality and integrity of their products. By partnering with Eurolab, you can

Ensure compliance with industry regulations

Predict real-world performance

Reduce product recalls and warranty claims

Improve brand reputation

Dont let regulatory non-compliance or subpar packaging materials put your business at risk. Contact us today to learn more about our simulated stress testing service and how we can help you guarantee the quality of your products.

Eurolab Your Partner in Quality Assurance

At Eurolab, were committed to helping businesses like yours meet the ever-growing demands of the market. With state-of-the-art technology and expert expertise, we provide tailored laboratory services that ensure compliance with industry regulations, predict real-world performance, and enhance product quality.

Trust us to help you navigate the complexities of packaging testing and ensure that your products meet the highest standards of quality and integrity. Contact us today to discuss your needs and let our experts guide you through the process of simulating stress conditions to evaluate elongation properties of packaging films.