Bond strength after immersion in solvents

The Crucial Factor in Product Durability Bond Strength after Immersion in Solvents

As a business owner in the field of material science and engineering, you understand the importance of product durability and reliability. One crucial factor that plays a significant role in determining the long-term performance of your products is their bond strength after immersion in solvents. Whether its a medical device, an automotive component, or a consumer product, exposure to various solvents can weaken its bond, leading to catastrophic failures.

At Eurolab, we specialize in providing laboratory services that help manufacturers like you ensure the reliability and safety of your products. Our Bond strength after immersion in solvents testing service is designed to simulate real-world conditions and provide you with accurate data on how your product will behave under various environmental stresses. In this article, well delve into the importance of bond strength after immersion in solvents, its advantages, key benefits, and answer frequently asked questions.

Why Bond Strength after Immersion in Solvents Matters

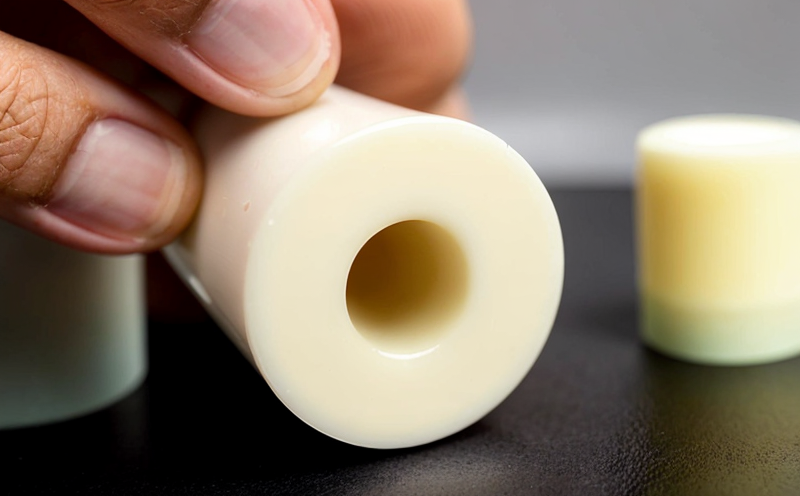

Bond strength refers to the mechanical interlocking between two or more materials, which is essential for maintaining their structural integrity. When a material is exposed to solvents, it can lead to degradation of the bond, compromising its performance and potentially causing catastrophic failures. This is especially true in industries where products are subjected to harsh environmental conditions, such as extreme temperatures, humidity, and exposure to various chemicals.

The consequences of inadequate bond strength after immersion in solvents can be severe

Product failure

Customer dissatisfaction

Damage to brand reputation

Financial losses

To mitigate these risks, manufacturers need accurate data on the bond strength of their products under simulated real-world conditions. This is where Eurolabs Bond strength after immersion in solvents testing service comes into play.

Advantages of Using Bond Strength after Immersion in Solvents

Our Bond strength after immersion in solvents testing service offers numerous advantages over traditional testing methods

Accurate results Our state-of-the-art equipment and experienced technicians ensure accurate data on bond strength, enabling you to make informed decisions about product design and development.

Time-saving With our rapid testing capabilities, you can quickly assess the durability of your products and identify areas for improvement.

Cost-effective By simulating real-world conditions in a laboratory setting, we help you avoid costly re-designs, production delays, or even recalls.

Compliance with regulations Our testing services ensure that your products meet industry standards and regulatory requirements.

Key Benefits of Bond Strength after Immersion in Solvents Testing

Here are the key benefits of our Bond strength after immersion in solvents testing service

Improved product design With accurate data on bond strength, you can refine your product design to enhance its durability and performance.

Enhanced customer satisfaction By ensuring that your products meet or exceed industry standards, youll reduce the risk of product failures and customer dissatisfaction.

Increased market competitiveness Our testing services help you stay ahead of the competition by identifying areas for improvement and implementing effective solutions.

Reduced warranty claims With our Bond strength after immersion in solvents testing service, you can minimize warranty claims and associated costs.

Frequently Asked Questions (FAQs)

Q What is bond strength, and why is it important?

A Bond strength refers to the mechanical interlocking between two or more materials. Its essential for maintaining their structural integrity, especially when exposed to harsh environmental conditions.

Q How does Eurolabs Bond strength after immersion in solvents testing service work?

A Our expert technicians use state-of-the-art equipment to simulate real-world conditions and assess bond strength under various solvent exposures.

Q What types of products can be tested using your Bond strength after immersion in solvents service?

A We test a wide range of products, including medical devices, automotive components, consumer goods, and more.

Q How long does the testing process take?

A Our rapid testing capabilities enable us to provide results quickly, usually within a few days or weeks, depending on the complexity of the test.

Q Are your testing services compliant with industry standards and regulations?

A Yes, our Bond strength after immersion in solvents testing service is designed to meet or exceed industry standards and regulatory requirements.

Conclusion

In conclusion, bond strength after immersion in solvents is a critical factor that determines the long-term performance and reliability of products. At Eurolab, we offer a comprehensive laboratory testing service that simulates real-world conditions to provide accurate data on bond strength. By using our Bond strength after immersion in solvents testing service, manufacturers can improve product design, enhance customer satisfaction, increase market competitiveness, and reduce warranty claims.

Dont let inadequate bond strength compromise your products performance. Trust Eurolabs expertise and state-of-the-art equipment to ensure the reliability and safety of your products. Contact us today to learn more about our Bond strength after immersion in solvents testing service and take the first step towards a safer, more durable product line.