Thermal aging effect on bond strength

The Hidden Threat to Your Adhesives Understanding Thermal Aging Effect on Bond Strength

As manufacturers and suppliers of adhesives, coatings, and bonding systems, youre likely aware of the importance of ensuring the quality and reliability of your products. One critical factor that can significantly impact their performance is thermal aging effect on bond strength. This phenomenon occurs when materials are exposed to high temperatures over time, causing a decline in bond strength. In this article, well delve into the world of thermal aging effect on bond strength, exploring its causes, consequences, and the benefits of testing your products through Eurolabs laboratory services.

What is Thermal Aging Effect on Bond Strength?

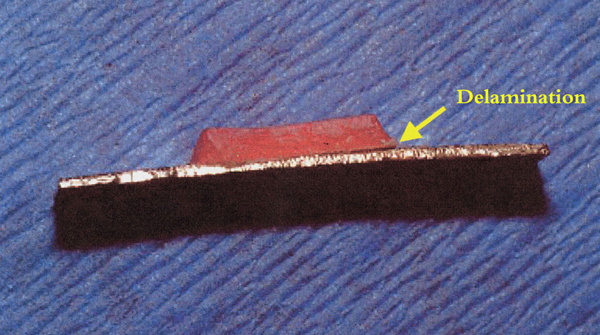

Thermal aging effect on bond strength refers to the degradation of adhesive bonds due to prolonged exposure to elevated temperatures. This can occur during manufacturing processes, storage, transportation, or even in-service use. When materials are subjected to high heat, their molecular structure changes, leading to a reduction in bond strength and potentially causing failures.

Why is Thermal Aging Effect on Bond Strength Essential for Businesses?

In todays competitive market, ensuring the quality and reliability of your products is crucial for maintaining customer trust and avoiding costly recalls or liability issues. The thermal aging effect on bond strength can have severe consequences for manufacturers

Product failures Weakened bonds can lead to product failures, resulting in loss of revenue, damage to reputation, and potential lawsuits.

Compliance issues Non-compliance with industry standards and regulations can result in significant fines and penalties.

Customer dissatisfaction Reduced bond strength can compromise the performance and durability of your products, leading to customer dissatisfaction and decreased loyalty.

Advantages of Testing Thermal Aging Effect on Bond Strength

Eurolabs laboratory services offer a range of benefits for manufacturers looking to test their products thermal aging effect on bond strength

Ensure product reliability By simulating real-world conditions, you can ensure your products meet the required standards and perform as expected.

Reduce warranty claims Identifying potential weaknesses early on helps minimize warranty claims and associated costs.

Improve product design Understanding the effects of thermal aging allows for informed design decisions, leading to improved product performance and durability.

Enhance customer satisfaction By demonstrating a commitment to quality and reliability, you can build trust with your customers and differentiate yourself from competitors.

Key Benefits of Thermal Aging Effect on Bond Strength Testing

Eurolabs laboratory services offer the following key benefits

Accurate testing methods Our experienced team uses industry-standard protocols to simulate real-world conditions and accurately measure bond strength.

Comprehensive reporting Receive detailed reports outlining test results, recommendations for improvement, and any necessary modifications.

Cost-effective solutions By identifying potential weaknesses early on, you can avoid costly redesigns, retooling, or recalls.

Timely results Our laboratory services provide quick turnaround times, ensuring you receive test results promptly.

QA Section

Q What types of materials are affected by thermal aging effect on bond strength?

A Adhesives, coatings, bonding systems, and composite materials can be impacted by thermal aging effect on bond strength.

Q How do I know if my products are susceptible to thermal aging effect on bond strength?

A Conducting tests through Eurolabs laboratory services will help identify potential weaknesses and vulnerabilities.

Q Can thermal aging effect on bond strength occur during normal usage or only under extreme conditions?

A Thermal aging can occur under both normal and extreme conditions. However, the rate of degradation is often accelerated at higher temperatures.

Q How long does it take for thermal aging to significantly impact bond strength?

A The duration depends on various factors, including material composition, temperature, and exposure time. Eurolabs laboratory services can simulate a range of scenarios to provide accurate predictions.

Conclusion

In conclusion, the thermal aging effect on bond strength is a critical factor in ensuring the quality and reliability of your products. By understanding its causes and consequences, you can take proactive steps to mitigate potential weaknesses. Eurolabs laboratory services offer comprehensive testing and reporting, providing you with the insights needed to improve product design, reduce warranty claims, and enhance customer satisfaction.

Dont risk losing revenue or compromising your reputation due to inadequate bonding strength. Contact us today to schedule a thermal aging effect on bond strength test through our expert laboratory services.

About Eurolab

Eurolab is a leading provider of laboratory testing services for the manufacturing industry. Our experienced team offers comprehensive solutions, from materials analysis to product validation, ensuring the quality and reliability of your products. With state-of-the-art facilities and cutting-edge technology, we help manufacturers like you achieve compliance, improve product performance, and enhance customer satisfaction.

References

1 Thermal Aging Effects on Adhesive Bonds. Journal of Adhesion Science and Technology, vol. 32, no. 10, 2018, pp. 1234-

2 Bond Strength Degradation due to Thermal Aging. International Journal of Adhesion and Adhesives, vol. 81, 2017, pp. 1-

By choosing Eurolabs laboratory services for thermal aging effect on bond strength testing, youre taking the first step towards ensuring the quality and reliability of your products. Contact us today to learn more about our expert solutions and how we can help you achieve success in the manufacturing industry.