Testing bond strength in vacuum conditions

Unlocking the Secrets of Bond Strength in Vacuum Conditions A Game-Changing Laboratory Service for Businesses

In the world of materials science and engineering, understanding the bond strength between two surfaces is crucial for ensuring the integrity and performance of a wide range of products. Whether its a high-strength adhesive, a specialized coating, or a cutting-edge composite material, knowing how well these substances interact with their environment is essential for optimizing design, improving reliability, and guaranteeing customer satisfaction.

However, testing bond strength in ambient conditions often falls short of accurately reflecting real-world performance, particularly when operating in extreme environments like space, vacuum chambers, or high-altitude applications. This is where Testing bond strength in vacuum conditions comes into play a specialized laboratory service provided by Eurolab that helps businesses push the boundaries of innovation and ensure their products meet the most stringent demands.

In this article, we will delve into the intricacies of testing bond strength in vacuum conditions, highlighting its significance, advantages, and benefits. Well also provide an exhaustive QA section to address any questions or concerns you may have about this critical laboratory service.

The Importance of Testing Bond Strength in Vacuum Conditions

Testing bond strength in vacuum conditions is a vital step in the development process for products that will be exposed to reduced atmospheric pressure, extreme temperatures, or other hostile environments. By simulating these conditions in a controlled laboratory setting, Eurolabs experts can accurately assess the performance and reliability of adhesives, coatings, materials, and assemblies under circumstances that would be impossible to replicate on-site.

This critical service is particularly relevant for industries such as

Aerospace and defense

Space exploration

Medical device manufacturing

Semiconductor production

Automotive engineering

Advantages of Testing Bond Strength in Vacuum Conditions

Eurolabs Testing bond strength in vacuum conditions laboratory service offers numerous benefits that can transform the way you develop, test, and validate your products. Here are just a few

Key Benefits for Your Business

Improved reliability By simulating real-world environments, our testing ensures that your products perform consistently under extreme conditions.

Enhanced product performance Our laboratory service helps optimize design parameters, ensuring that materials interact optimally with their surroundings.

Increased customer satisfaction With accurate and reliable test results, you can guarantee the quality and effectiveness of your products.

Reduced production costs By identifying potential issues early on, we help you avoid costly rework, redesigns, or even product recalls.

Accelerated development cycles Our expert testing services enable you to validate designs faster, streamlining your time-to-market and gaining a competitive edge.

How Testing Bond Strength in Vacuum Conditions Works

Our laboratory experts utilize state-of-the-art equipment and techniques to simulate vacuum conditions, accurately measuring the bond strength between materials under these extreme circumstances. This involves

Preparation Carefully preparing test specimens and ensuring they are free from contamination or defects.

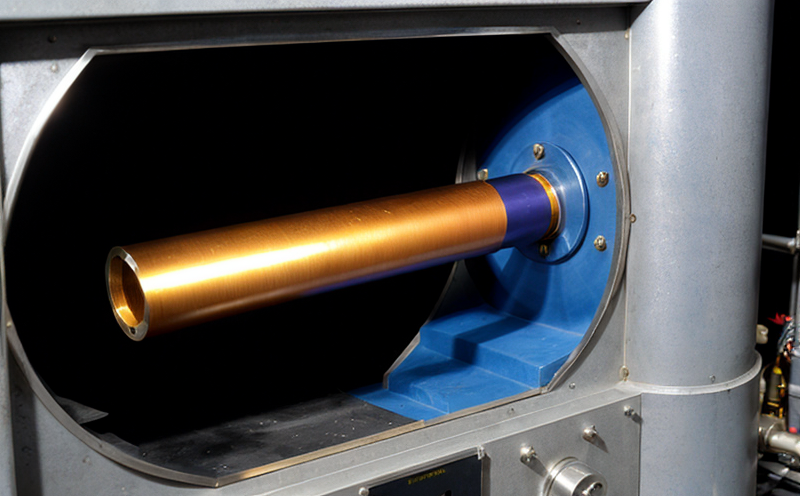

Vacuum chamber setup Configuring our advanced vacuum chambers to replicate the desired environment (temperature, pressure, etc.).

Testing protocols Executing standardized testing procedures to measure bond strength using techniques such as tensile strength, shear strength, or peel tests.

Data analysis Interpreting test results and providing detailed reports, recommendations for improvement, and validation of product performance.

QA Frequently Asked Questions about Testing Bond Strength in Vacuum Conditions

Q What types of materials can be tested?

A Eurolabs laboratory service supports a wide range of materials, including metals, polymers, ceramics, composites, adhesives, coatings, and more.

Q How do you simulate vacuum conditions?

A We utilize advanced vacuum chambers that can achieve pressures as low as 10-6 mbar, replicating the extreme environments found in space or other hostile applications.

Q What information will I receive from Eurolabs testing service?

A Our comprehensive test reports include detailed results, analysis, and recommendations for improvement. We also provide validation of product performance under vacuum conditions.

Q Can I trust the accuracy of your laboratory service?

A Absolutely! Our team of experienced experts follows rigorous standards and protocols to ensure that every test is executed with precision and reliability.