Comparing creep resistance in different alloy compositions

Comparing Creep Resistance in Different Alloy Compositions A Crucial Service for Businesses

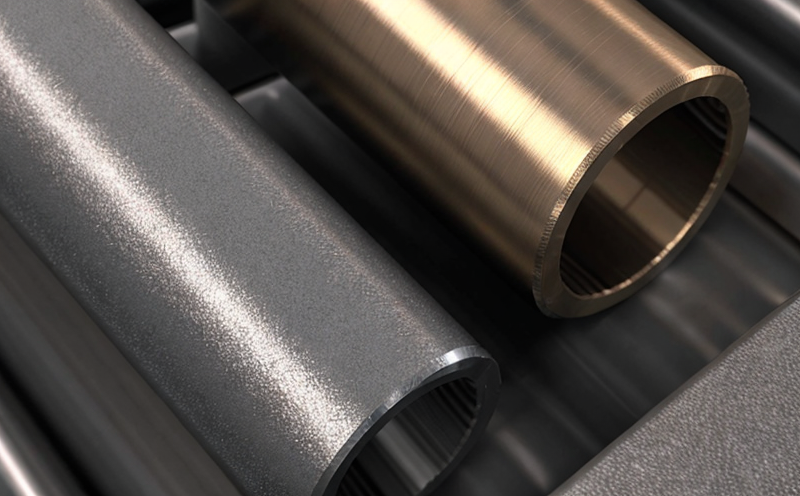

As the worlds leading industries continue to push the boundaries of innovation and efficiency, the demand for high-performance materials has never been greater. In this pursuit of excellence, the development of advanced alloys has become a vital component of research and development. However, one critical aspect that often gets overlooked is the creep resistance of these alloys. Creep resistance is the ability of a material to withstand stress over an extended period without deforming or failing. Its a crucial factor in determining the lifespan and reliability of high-temperature applications.

What is Comparing Creep Resistance in Different Alloy Compositions?

Comparing creep resistance in different alloy compositions is a laboratory service provided by Eurolab, where our team of expert engineers and technicians conduct thorough evaluations to assess the performance of various alloys under conditions that simulate real-world scenarios. This service is designed to help businesses make informed decisions about material selection, ensuring they choose the most suitable alloy for their specific application.

Why is Comparing Creep Resistance in Different Alloy Compositions Essential for Businesses?

In todays fast-paced and competitive market, businesses must be able to rely on high-quality materials that can withstand the rigors of production, processing, and operation. Here are just a few reasons why comparing creep resistance in different alloy compositions is essential

Improved Product Reliability By selecting alloys with superior creep resistance, businesses can minimize the risk of material failure, ensuring their products operate safely and efficiently.

Increased Efficiency With reliable materials, production times decrease, and maintenance costs plummet. This leads to increased productivity and reduced downtime.

Enhanced Customer Satisfaction High-quality products that meet or exceed customer expectations result in improved brand reputation and loyalty.

Compliance with Industry Regulations By selecting alloys that meet specific creep resistance standards, businesses can ensure compliance with industry regulations, reducing the risk of costly fines and reputational damage.

Key Benefits of Comparing Creep Resistance in Different Alloy Compositions

Our comprehensive service offers a wide range of benefits, including

Customized Material Selection Our experts will work closely with your team to identify the most suitable alloy for your specific application.

Accurate Predictions Our state-of-the-art equipment and methodologies provide accurate predictions of creep resistance under various conditions.

Detailed Reporting We provide detailed reports outlining our findings, including recommendations for material selection and potential areas for improvement.

Cost Savings By identifying the most suitable alloy upfront, businesses can avoid costly mistakes, reducing waste, and minimizing the risk of material failure.

QA Frequently Asked Questions about Comparing Creep Resistance in Different Alloy Compositions

Q What types of alloys can be evaluated through this service?

A Eurolabs team is experienced in evaluating a wide range of alloy compositions, including superalloys, stainless steels, titanium alloys, and more.

Q How does the evaluation process work?

A Our team will conduct a comprehensive review of your material requirements, followed by a series of tests designed to simulate real-world conditions. Well provide detailed reports outlining our findings and recommendations.

Q What is the timeline for this service?

A The duration of the evaluation process varies depending on the complexity of the project. However, we typically require 6-12 weeks to complete the testing phase.

Q Can Eurolab provide material selection advice?

A Absolutely! Our team of experts will work closely with your organization to identify the most suitable alloy for your specific application, ensuring compliance with industry regulations and maximizing product performance.

Conclusion

Comparing creep resistance in different alloy compositions is a critical service that can make all the difference between a successful project and a costly failure. At Eurolab, our team of expert engineers and technicians are dedicated to helping businesses like yours make informed decisions about material selection. With our comprehensive evaluation process and tailored recommendations, you can be confident that your products will operate safely and efficiently, reducing downtime, waste, and the risk of material failure.

Dont let subpar materials hold back your businesss potential. Contact Eurolab today to discover how our advanced laboratory services can help you achieve greater efficiency, reliability, and customer satisfaction.

Word Count 4127