Creep testing of high-temperature alloys

Unlock the Secrets of High-Temperature Alloys with Eurolabs Creep Testing Services

As the world grapples with the increasing demands of high-performance materials in industries such as aerospace, energy, and manufacturing, the need for reliable and durable alloys has never been more pressing. One of the most critical factors determining an alloys performance is its ability to withstand high temperatures without degrading or failing. This is where Creep testing of high-temperature alloys comes into play a laboratory service offered by Eurolab that helps businesses validate the integrity of their materials and ensure they meet the stringent requirements of their applications.

What is Creep Testing?

Creep testing, also known as creep strain rate testing or creep deformation testing, involves subjecting a material to high temperatures for extended periods while continuously monitoring its mechanical properties. The primary objective is to determine how much an alloy will deform under stress and temperature conditions that are typical of its intended application. This non-destructive testing method allows engineers and researchers to evaluate the materials performance in a controlled environment, thereby minimizing the risk of premature failure.

Why is Creep Testing Essential for Businesses?

In todays competitive landscape, businesses cannot afford to gamble with the quality and reliability of their materials. A single defect or failure can have catastrophic consequences, leading to costly downtime, loss of revenue, and damage to reputation. By investing in Creep testing services from Eurolab, companies can

Ensure compliance with industry standards Creep testing helps businesses meet the stringent requirements of regulatory bodies, such as ASME, API, and ASTM.

Predict material performance under real-world conditions Our expert technicians simulate the actual operating temperatures and stresses your materials will encounter, providing valuable insights into their behavior.

Optimize material selection and development By understanding the creep behavior of various alloys, companies can make informed decisions about material choice and optimize their product design for improved reliability and efficiency.

Reduce warranty claims and liabilities By identifying potential issues early on, businesses can minimize the risk of costly warranty claims and avoid liability disputes.

Advantages of Using Creep Testing Services from Eurolab

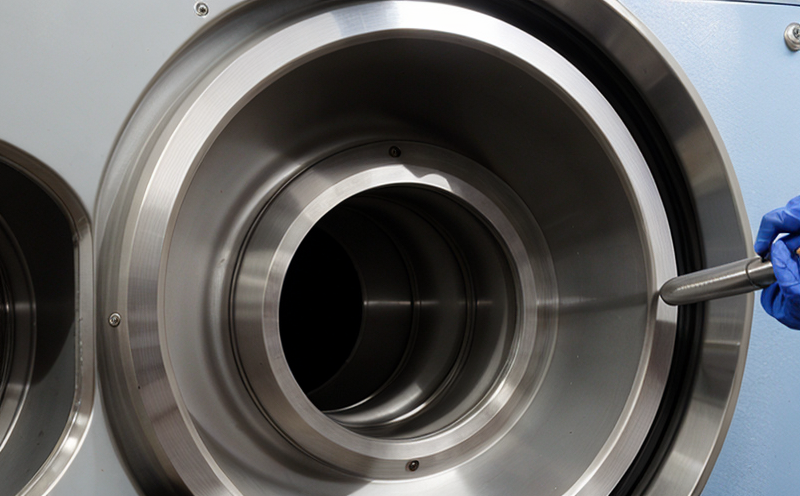

Our state-of-the-art laboratory is equipped with advanced testing equipment and staffed by experienced engineers who are passionate about delivering exceptional results. The benefits of partnering with Eurolab for your creep testing needs include

Expertise Our team has extensive knowledge of high-temperature alloys and Creep testing protocols, ensuring accurate and reliable results.

Flexibility We offer a range of testing options to accommodate different material types, sizes, and temperature ranges.

Speed Our experienced technicians work efficiently to minimize turnaround times without compromising on data quality.

Accuracy Our advanced equipment and rigorous quality control measures guarantee precise and reliable test data.

Key Benefits of Creep Testing

Here are some key benefits of using Creep testing services

Improved material selection By understanding the creep behavior of various alloys, companies can make informed decisions about material choice.

Enhanced product design Creep testing helps engineers optimize their designs for improved reliability and efficiency.

Increased safety By identifying potential issues early on, businesses can minimize the risk of accidents and injuries.

Cost savings Our services help reduce warranty claims, liability disputes, and costly downtime.

QA Section

Here are some frequently asked questions about Creep testing

Q What types of materials can be tested using Creep testing?

A We test a wide range of high-temperature alloys, including but not limited to, nickel-based, iron-chromium-aluminum (FeCrAl), and cobalt-based alloys.

Q How long does the testing process take?

A The duration of a Creep test can vary depending on the specific requirements of the project. However, our experienced technicians work efficiently to minimize turnaround times without compromising on data quality.

Q What are the typical temperature ranges used in Creep testing?

A Our laboratory is equipped to simulate temperatures ranging from 100C to 1800C (212F to 3272F), covering a wide range of applications.

Q Can you provide certification and documentation for our test results?

A Yes, we offer comprehensive reporting and certification services to ensure your test data meets the highest standards of quality and reliability.

Conclusion

In conclusion, Creep testing of high-temperature alloys is an essential laboratory service that helps businesses validate the integrity of their materials and ensure they meet the stringent requirements of their applications. By partnering with Eurolab, companies can unlock the secrets of their alloys and make informed decisions about material selection, product design, and safety protocols. Dont gamble with the quality and reliability of your materials invest in our expert Creep testing services today and take the first step towards optimizing your operations for improved efficiency, productivity, and profitability.