Unraveling the Mysteries of Creep Testing Unlocking Material Secrets for a Safer and More Efficient World

In todays fast-paced industrial landscape, materials play a crucial role in shaping our world. From the intricate components of high-speed trains to the robust frameworks of offshore oil platforms, the reliability and durability of materials are paramount to ensuring public safety, minimizing downtime, and maximizing efficiency. However, even the most seemingly robust materials can exhibit unexpected behavior under prolonged stress, leading to catastrophic failures that have devastating consequences.

This is where Creep Testing comes into play a sophisticated laboratory service provided by Eurolab that enables businesses to predict and mitigate material degradation, thereby safeguarding their operations and stakeholders. In this article, we will delve into the world of Creep Testing, exploring its fundamental principles, advantages, applications, and benefits. By the end of this comprehensive guide, youll understand why investing in Creep Testing is a no-brainer for any organization seeking to guarantee the integrity of their materials.

What is Creep Testing?

Creep Testing is an experimental technique used to evaluate the long-term deformation behavior of materials under constant stress or load. By applying controlled amounts of pressure and heat, engineers can monitor how materials respond over extended periods, typically ranging from several days to months or even years. This process provides invaluable insights into a materials potential for creep a phenomenon characterized by gradual, irreversible deformation that can lead to failure.

Why is Creep Testing essential?

In todays world, where products and structures are becoming increasingly complex, the risk of creep-related failures is on the rise. Whether its a power plant turbine, an aerospace component, or an offshore drilling rig, any system prone to high stresses and temperatures requires meticulous testing to ensure its integrity. By employing Creep Testing, businesses can

Prevent catastrophic failures Uncover potential material weaknesses before they become major concerns, thereby minimizing the risk of accidents and costly downtime.

Optimize material selection Identify the most suitable materials for specific applications based on their creep behavior under various conditions.

Enhance product lifespan Determine the long-term durability of products and structures to extend their service life and reduce maintenance costs.

Key Benefits of Creep Testing

Improved Safety By predicting potential failures, businesses can safeguard human lives, prevent environmental disasters, and protect equipment and assets from damage.

Increased Efficiency With reliable material data, engineers can design more efficient systems, reducing energy consumption and minimizing waste.

Cost Savings Avoiding costly repairs, replacements, and downtime ensures significant savings for companies across various industries.

Enhanced Innovation Creep Testing enables researchers to push the boundaries of materials science, driving innovation in fields like aerospace, energy, and construction.

Compliance with Regulations Eurolabs expert services ensure that your products meet stringent industry standards and regulatory requirements.

How does Creep Testing work?

The Creep Testing process involves carefully controlled conditions, including

Temperature Materials are subjected to precise temperature profiles, simulating real-world operating conditions.

Stress Applied loads range from tens of megapascals to hundreds of gigapascals, mimicking the stresses experienced by products in service.

Time Long-duration testing provides critical insights into material behavior over extended periods.

QA Section

Q What types of materials are suitable for Creep Testing?

A Eurolab specializes in testing various materials, including metals (alloys and pure), polymers, ceramics, composites, and advanced nanomaterials.

Q How do I prepare my samples for testing?

A Our experienced team will guide you through the preparation process to ensure your samples are properly cleaned, machined, and packaged for safe transportation.

Q What kind of data can I expect from a Creep Testing program?

A Eurolab provides comprehensive reports detailing creep strain, stress relaxation, and other relevant metrics. This data is invaluable for material selection, design optimization, and predictive modeling.

Q Can Creep Testing be conducted on site or at your laboratory?

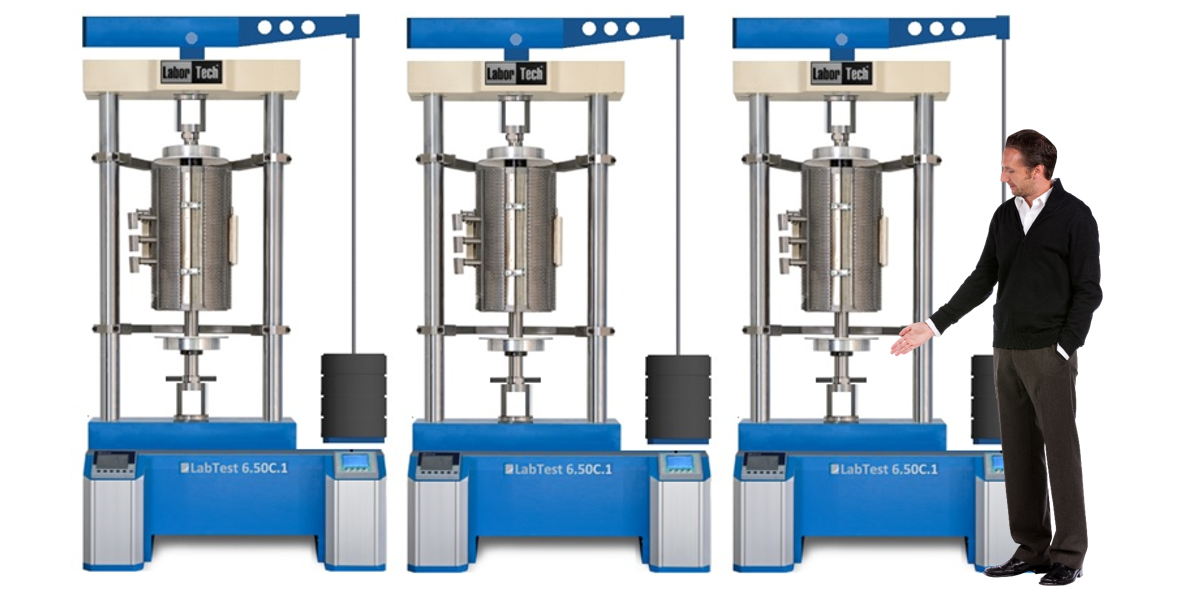

A While some tests can be performed in-house, many require specialized equipment and controlled environments found only in our state-of-the-art laboratories.

Q Are the results of Creep Testing confidential?

A Absolutely. Eurolab is committed to maintaining confidentiality for all clients, ensuring that sensitive data remains protected throughout the testing process.

By investing in Creep Testing services from Eurolab, your organization can gain a competitive edge through

Predictive maintenance Proactively scheduling repairs and replacements based on material performance.

Material selection optimization Choosing the best materials for specific applications to reduce costs and enhance efficiency.

Risk reduction Minimizing the likelihood of catastrophic failures by identifying potential issues early.

Join the ranks of forward-thinking companies that prioritize their customers safety and success. Contact Eurolab today to learn more about our Creep Testing services and discover how we can help your business thrive in a world where material integrity matters most.