Crack initiation detection

Crack Initiation Detection Unleash the Power of Predictive Maintenance with Eurolab

In todays fast-paced industrial landscape, equipment reliability is crucial for businesses to stay competitive and minimize downtime. However, even with rigorous maintenance schedules, machinery can still develop cracks, leading to catastrophic failures and significant economic losses. Crack initiation detection is a vital laboratory service that helps predict potential material failures, ensuring the longevity of your assets and safeguarding your bottom line.

At Eurolab, we specialize in providing high-precision crack initiation detection services to industries worldwide. Our cutting-edge technology and expert analysts enable us to identify micro-cracks before they become major issues, saving you time, money, and resources.

The Importance of Crack Initiation Detection

Crack initiation is a critical phenomenon that can occur in any material subjected to stress or fatigue. Its a subtle process where small cracks form on the surface or within the material, often without visible signs. If left unchecked, these micro-cracks can rapidly propagate, leading to catastrophic failures and equipment downtime.

In industries such as aerospace, energy, and manufacturing, crack initiation can have severe consequences, including

Reduced product lifespan

Increased maintenance costs

Equipment damage or replacement

Loss of productivity and revenue

Benefits of Crack Initiation Detection with Eurolab

Our expert laboratory services offer numerous benefits to businesses looking to minimize risks associated with material failures. Here are some key advantages of using crack initiation detection

Predictive Maintenance Identify potential material failures before they occur, allowing you to schedule maintenance or repairs proactively.

Increased Equipment Life Extend the lifespan of your assets by detecting and addressing micro-cracks early on, reducing the need for premature replacements.

Cost Savings Minimize downtime, maintenance costs, and replacement expenses associated with equipment failure.

Improved Safety Reduce the risk of accidents and injuries caused by material failures, ensuring a safer working environment.

Enhanced Product Quality Ensure that your products meet or exceed industry standards by detecting and addressing potential material issues early on.

Crack Initiation Detection Process

Our crack initiation detection process involves the following steps

Sampling We collect samples from your equipment or materials, which are then transported to our state-of-the-art laboratory.

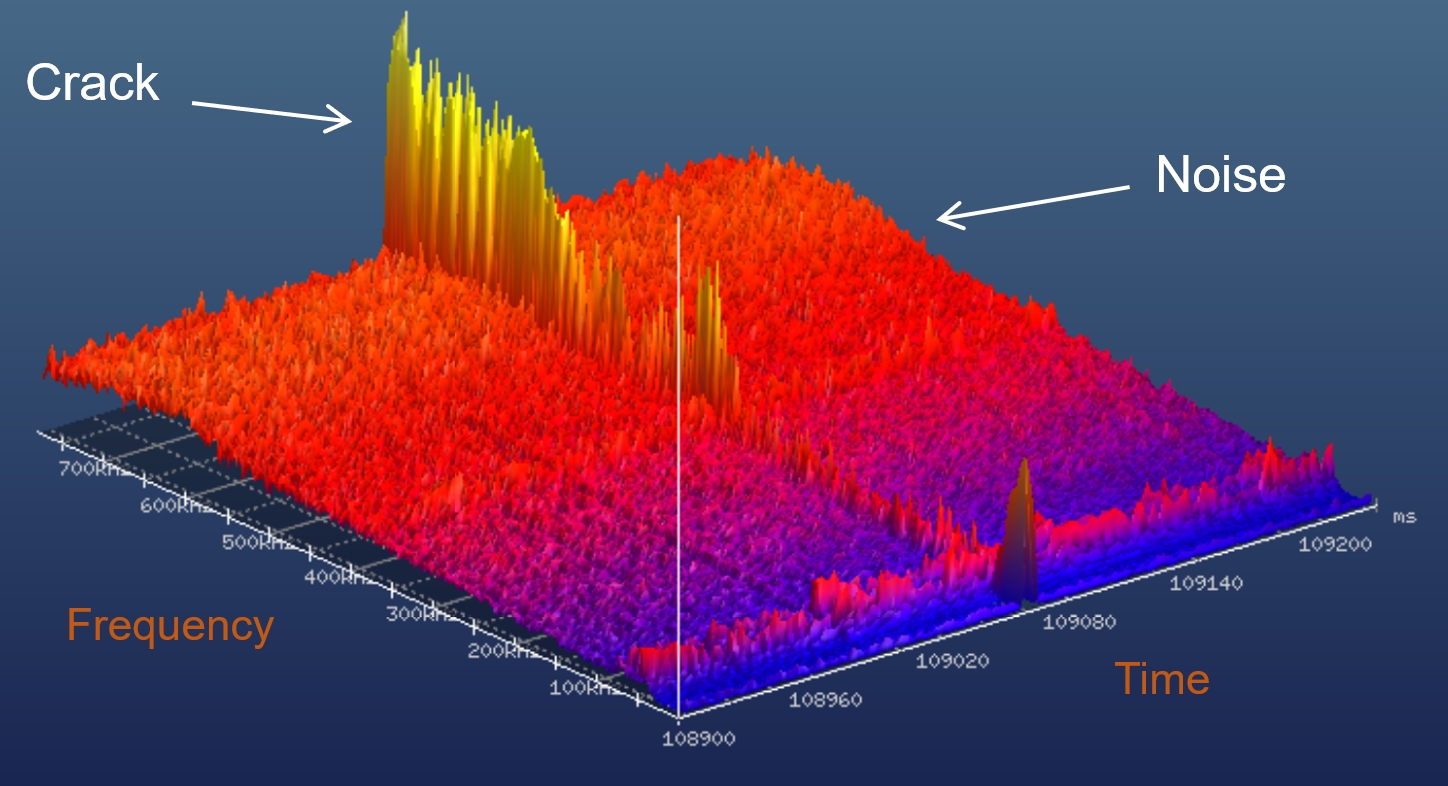

Non-Destructive Testing (NDT) Our expert analysts use advanced NDT techniques, such as ultrasonic testing and radiography, to detect micro-cracks on the surface and within the material.

Material Analysis We analyze the samples material composition and structure to identify potential weaknesses or defects that may contribute to crack initiation.

Crack Initiation Detection Using advanced software and algorithms, we detect and quantify the presence of micro-cracks, identifying their location, size, and orientation.

QA Frequently Asked Questions

Weve compiled a list of frequently asked questions to help you better understand our crack initiation detection services

Q What types of materials can be tested for crack initiation?

A We can test various materials, including metals, alloys, ceramics, and polymers.

Q How do I collect samples for testing?

A Please follow our guidelines for collecting representative samples from your equipment or materials. If youre unsure, contact us for assistance.

Q What is the turnaround time for crack initiation detection results?

A Our laboratory team works efficiently to provide results within a few days of receiving the sample.

Q Can I request customized testing services?

A Yes, we offer tailored testing packages to meet your specific needs and requirements.

Conclusion

Crack initiation detection is an essential service that helps businesses predict potential material failures and minimize downtime. At Eurolab, our expert analysts use cutting-edge technology to detect micro-cracks before they become major issues. By leveraging the power of predictive maintenance with crack initiation detection, you can ensure the longevity of your assets, safeguard your bottom line, and maintain a competitive edge in your industry.

Dont wait until its too late contact us today to learn more about our crack initiation detection services and how we can help you mitigate material failure risks.