Dynamic force application

Unlocking Product Performance with Dynamic Force Application A Game-Changing Laboratory Service

In the competitive world of product development and testing, businesses are constantly seeking innovative ways to improve their products performance, reliability, and lifespan. One crucial laboratory service that has revolutionized the industry is Dynamic Force Application (DFA). This cutting-edge technology enables manufacturers to simulate real-world forces on materials and products, providing invaluable insights into their behavior under various conditions.

As a leading provider of DFA services, Eurolab helps businesses optimize their product design, material selection, and manufacturing processes. In this article, we will delve into the world of Dynamic Force Application, exploring its significance, benefits, and applications in various industries.

What is Dynamic Force Application?

Dynamic Force Application is a laboratory technique that involves applying controlled forces to materials or products under various loading conditions, simulating real-world scenarios such as impacts, vibrations, and compressions. This service enables manufacturers to evaluate their products performance under dynamic loads, ensuring they meet the required standards for safety, durability, and efficiency.

Why is Dynamic Force Application Essential for Businesses?

The importance of DFA in todays industry cannot be overstated. By leveraging this technology, businesses can

Enhance Product Reliability Identify potential weaknesses and areas for improvement, leading to more reliable products that minimize failures and downtime.

Reduce Testing Time and Costs Eliminate the need for expensive and time-consuming physical testing, allowing companies to quickly validate product designs and materials.

Improve Material Selection Select the most suitable materials for a particular application, ensuring optimal performance and minimizing the risk of material failure.

Key Benefits of Dynamic Force Application

Here are some of the most significant advantages of using DFA services

Increased Product Safety By simulating real-world forces, manufacturers can identify potential safety risks and make necessary design changes to prevent accidents.

Improved Material Efficiency Selecting the right materials for a product can significantly reduce production costs, energy consumption, and waste generation.

Enhanced Durability DFA helps manufacturers design products that withstand various environmental conditions, such as extreme temperatures, humidity, and vibrations.

Competitive Advantage Companies that adopt DFA services can differentiate themselves from competitors by offering high-performance, reliable products that meet or exceed industry standards.

Industry Applications of Dynamic Force Application

DFA is a versatile technology with applications across various industries

Aerospace and Defense Evaluate the performance of materials under extreme temperatures, impact loads, and vibrations.

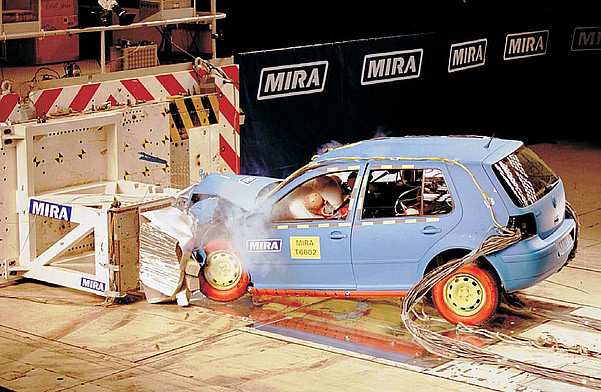

Automotive Test vehicle components for crashworthiness, fatigue resistance, and vibration tolerance.

Energy Storage Assess battery performance under dynamic loads, ensuring safe and efficient energy storage solutions.

Medical Devices Simulate real-world forces on medical implants, prosthetics, and other devices to ensure patient safety.

QA Frequently Asked Questions about Dynamic Force Application

What types of products can be tested using DFA?

Dynamic Force Application is suitable for a wide range of products, including components, materials, and finished goods.

How does DFA differ from traditional physical testing?

DFA simulates real-world forces on products under various loading conditions, whereas traditional physical testing involves applying fixed loads to products in a laboratory setting.

What are the benefits of using DFA over other laboratory services?

DFA offers faster and more cost-effective results than traditional testing methods, with improved material efficiency and product safety.

Can DFA be used for multiple industries or applications?

Yes, DFA is a versatile technology that can be applied to various industries, including aerospace, automotive, energy storage, medical devices, and more.

Conclusion

Dynamic Force Application is an innovative laboratory service that has revolutionized the industry by providing manufacturers with invaluable insights into product performance under dynamic loads. By leveraging Eurolabs DFA services, businesses can enhance their products reliability, safety, and durability while reducing testing time and costs. Whether youre a seasoned manufacturer or a newcomer to the industry, embracing DFA technology is essential for staying ahead of the competition.

Join the ranks of forward-thinking companies that have already benefited from Dynamic Force Application. Contact us today to discover how our expert team can help your business unlock product performance potential with Eurolabs cutting-edge laboratory services.