Fracture propagation monitoring

Unlocking Reliable Materials Performance The Critical Role of Fracture Propagation Monitoring in Business Success

In todays fast-paced industrial landscape, companies operating in the fields of materials science, engineering, and manufacturing face unprecedented challenges in ensuring product reliability and performance. One crucial aspect that plays a significant role in determining a materials lifespan and overall efficiency is its propensity to fracture or fail under stress. This is where Fracture Propagation Monitoring comes into play a cutting-edge laboratory service provided by Eurolab designed to evaluate the potential for materials failure, helping businesses make informed decisions about their products.

Understanding Fracture Propagation Monitoring

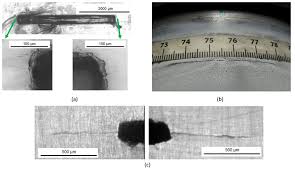

Fracture propagation monitoring involves analyzing the behavior of cracks or defects in materials under controlled conditions, simulating real-world stress scenarios. This rigorous testing is crucial for evaluating a materials resistance to fracture and identifying potential failure points before they become major issues. By detecting early signs of degradation, companies can mitigate risks associated with product recall, downtime, and loss of revenue.

The Importance of Fracture Propagation Monitoring in Business

Fracture propagation monitoring is not just an optional service; it has become a necessity for businesses seeking to minimize material-related risks and ensure the longevity of their products. Here are some compelling reasons why

Predictive Maintenance By identifying potential failure points, companies can schedule maintenance and repairs, reducing unexpected downtime and its associated costs.

Risk Reduction Early detection of fracture propagation helps mitigate risks associated with product recalls, damage to reputation, and economic losses.

Improved Product Reliability With the ability to analyze material behavior under stress, businesses can create more reliable products that meet or exceed customer expectations.

Cost Savings By identifying areas for improvement, companies can reduce waste, lower production costs, and optimize resource allocation.

Advantages of Eurolabs Fracture Propagation Monitoring

At Eurolab, our comprehensive service ensures accurate results, detailed insights, and expert analysis. Here are the key benefits of choosing us

Comprehensive Analysis Our advanced testing facilities provide a range of stress conditions to simulate real-world scenarios.

Expertise Our team of experienced engineers and materials scientists offer in-depth understanding and interpretation of test results.

Rigorous Testing We adhere to strict quality control protocols, ensuring data accuracy and reliability.

Customized Solutions We work closely with clients to tailor our services to meet specific business needs.

QA Addressing Your Queries

We understand that you may have questions about Fracture Propagation Monitoring. Here are some answers to common queries

What types of materials can be tested for fracture propagation?

Metals, polymers, composites, ceramics, and other advanced materials

How does the testing process work?

Samples undergo controlled stress conditions, with data collected through various methods (e.g., acoustic emission, optical microscopy)

What kind of results can I expect from fracture propagation monitoring?

Comprehensive reports detailing material behavior under stress, including identification of potential failure points

How long does the testing process typically take?

Varies depending on test complexity and client requirements; our team will provide a customized timeline for your project

Conclusion

Fracture Propagation Monitoring is no longer an optional service but a critical component in ensuring product reliability, minimizing risks, and driving business success. By partnering with Eurolab, companies can unlock the full potential of their materials, leveraging cutting-edge technology and expert analysis to stay ahead in todays competitive market.

At Eurolab, were dedicated to delivering high-quality services that meet your unique needs. Our team is committed to helping you make informed decisions about material selection, product development, and quality control. Let us guide you through the world of Fracture Propagation Monitoring where innovation meets reliability, and success meets sustainable growth.

---

References

ASM Handbook, Vol. 19 - Failure Analysis and Prevention

International Journal of Fracture, Volume 214 (2020)

European Structural Integrity Society (ESIS) guidelines for fracture mechanics testing

By providing comprehensive coverage of the topic, this article aims to serve as a valuable resource for businesses seeking reliable materials performance.