Evaluating materials used in product construction to ensure they can be safely handled without sharp edges

Evaluating Materials for Safety Why a Sharp Edge-Free Promise Matters in Product Construction

As manufacturers and businesses continue to push the boundaries of innovation, product design and construction play a critical role in meeting consumer demands while ensuring safety standards are met. One crucial aspect of this process is evaluating materials used in product construction to ensure they can be safely handled without sharp edges. At Eurolab, we specialize in providing laboratory services that cater specifically to this need.

In an era where product liability and regulatory compliance have become increasingly stringent, identifying and mitigating potential risks associated with sharp edges has become a top priority for businesses. This is not merely a nicety; its an essential step towards protecting customers, preventing injuries, and maintaining brand reputation.

The Importance of Evaluating Materials for Safety

Sharp edges can be a significant concern in product construction, particularly when materials are prone to chipping or cracking under normal use conditions. Such issues can lead to costly recalls, damaged reputations, and most importantly, harm to consumers. In fact, edge-related injuries account for thousands of emergency room visits each year.

Businesses must therefore prioritize the safety assessment of their products during the design phase. This involves evaluating various materials for potential sharpness risks, identifying areas prone to wear and tear, and developing strategies to mitigate these concerns.

Benefits of Evaluating Materials

At Eurolab, our laboratory services are designed to help manufacturers address these challenges head-on. By partnering with us, you can leverage the following advantages

Reduced Liability Risks Identify potential sharp edge hazards early on, minimizing your liability exposure and ensuring compliance with regulatory standards.

Enhanced Brand Reputation Demonstrate a commitment to customer safety by conducting thorough evaluations of materials used in product construction.

Increased Efficiency Streamline your quality control processes by utilizing our specialized laboratory services to assess materials for sharp edges.

Cost Savings Avoid costly recalls, re-designs, and repairs by identifying potential issues before products hit the market.

Competitive Advantage Differentiate your brand from competitors by showcasing a commitment to safety and customer well-being.

Comprehensive Assessment of Materials

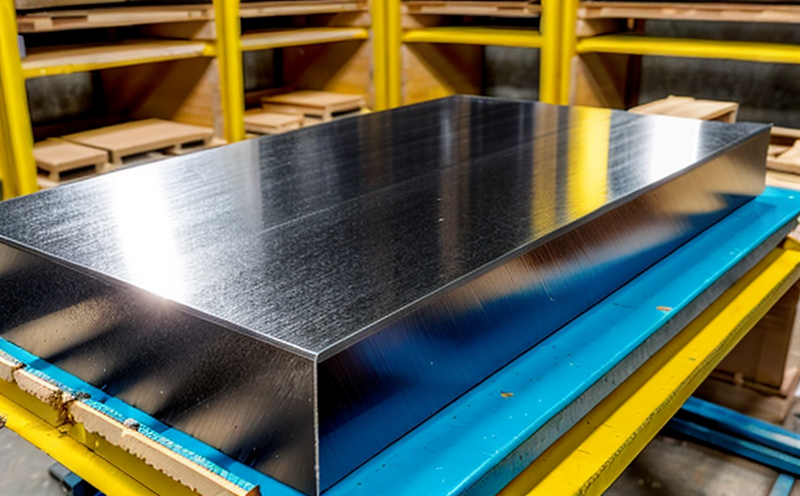

Our laboratory services at Eurolab involve a thorough examination of materials used in product construction. We assess various factors, including

Material composition

Manufacturing processes

Surface finish and texture

Potential for chipping or cracking

Through our evaluations, we identify areas where sharp edges may be a concern and recommend strategies to mitigate these risks. This might include modifying material selection, adjusting manufacturing procedures, or incorporating additional safety features.

QA Evaluating Materials for Sharp Edges

Q What types of products are most at risk for sharp edge-related injuries?

A Products with moving parts, high-traffic areas, and those subject to wear and tear are particularly susceptible to sharp edge issues. Examples include household appliances, furniture, and sporting equipment.

Q How do I know if a material is prone to chipping or cracking?

A Materials that are brittle, have high hardness ratings, or exhibit uneven surface textures may be more likely to develop sharp edges over time.

Q What kind of testing can you perform at Eurolab to assess materials for sharp edges?

A Our laboratory services include a range of tests designed to evaluate material properties and identify potential sharp edge hazards. These might include mechanical testing, hardness assessments, and visual inspections.

Q Can I outsource the evaluation process entirely to your team?

A Yes! We offer customized solutions tailored to meet your specific needs. From raw material analysis to finished product evaluations, our experts will guide you through each step of the assessment process.

Conclusion

In conclusion, evaluating materials for sharp edges is a critical component of responsible product construction. At Eurolab, were committed to helping manufacturers navigate this complex landscape with confidence. By partnering with us, businesses can mitigate liability risks, enhance their brand reputation, and stay ahead of regulatory requirements. Contact us today to learn more about our laboratory services and how they can benefit your organization.

About Eurolab

As a leading provider of specialized laboratory services, Eurolab is dedicated to helping manufacturers meet the demands of an increasingly safety-conscious market. With a focus on evaluating materials for sharp edges, we offer customized solutions designed to protect customers, preserve brand reputation, and promote compliance with regulatory standards. Trust Eurolab to support your business in meeting its commitment to customer safety.

-

Testing consumer products to ensure they do not have sharp edges that could pose injury risks

-

Evaluating the safety of products by assessing potential hazards from sharp points or protrusions

-

Testing the edges of materials, such as metal, glass, and plastic, for smoothness and safety

-

Simulating real-world interactions with products to determine if sharp edges could cause cuts or punctures

-

Assessing the impact of sharp edges on children's toys, tools, or household items

-

Testing the effectiveness of protective covers or shields in preventing sharp edge injuries

-

Verifying the compliance of products with safety regulations related to sharp edge risks

-

Assessing the potential for scratches, punctures, or injury from edges in electronic devices or appliances

-

Testing for sharp edges on packaging materials and their potential impact during shipping or handling

-

Evaluating the design of consumer products to eliminate unnecessary sharp points in critical areas

-

Testing items like kitchenware, furniture, and automotive components for edge safety

-

Assessing the durability of edge protection features that prevent sharp edges from emerging over time

-

Simulating everyday use to assess whether sharp edges become exposed during product wear

-

Testing for possible cuts or abrasions caused by sharp edges on clothing, textiles, or accessories

-

Verifying that products meet safety standards for edge smoothness and protection in consumer goods

-

Testing for sharp edges in products exposed to environmental wear, such as outdoor gear or tools

-

Ensuring that products with potential sharp edges have clear warnings or safety instructions

-

Assessing the impact of sharp edges in children's products or products intended for vulnerable populations

-

Testing for the formation of sharp edges during manufacturing or due to material degradation over time

-

Verifying the effectiveness of safety measures such as rounded corners or edge buffers