Verifying that products meet safety standards for edge smoothness and protection in consumer goods

Verifying that Products Meet Safety Standards for Edge Smoothness and Protection in Consumer Goods A Crucial Laboratory Service by Eurolab

In todays fast-paced consumer goods market, manufacturers are constantly seeking innovative ways to ensure the safety and quality of their products. One critical aspect of product development is verifying that finished goods meet stringent safety standards for edge smoothness and protection. This laboratory service, provided by Eurolab, plays a vital role in safeguarding consumers from potential hazards associated with sharp or rough edges on consumer goods.

The Importance of Edge Smoothness and Protection

Edge smoothness and protection are essential considerations in the production of consumer goods, including household items, personal care products, packaging materials, and more. A products edge can pose a significant risk to users, particularly children and individuals with disabilities. Inadequate edge treatment or finishing can lead to serious injuries, such as cuts, lacerations, or even amputations.

Advantages of Using Eurolabs Verifying that Products Meet Safety Standards for Edge Smoothness and Protection

Eurolabs laboratory service offers numerous benefits to manufacturers seeking to ensure their products meet the required safety standards. Some of these advantages include

Enhanced Product Safety By verifying edge smoothness and protection, manufacturers can significantly reduce the risk of product-related injuries.

Compliance with Regulatory Requirements Meeting or exceeding industry standards for edge smoothness and protection demonstrates a companys commitment to regulatory compliance.

Increased Consumer Trust By investing in Eurolabs laboratory service, manufacturers can enhance their brand reputation and foster trust among consumers.

Reduced Liability Manufacturers who verify edge smoothness and protection through Eurolabs service are better equipped to mitigate liability in the event of product-related injuries.

Improved Product Design Collaboration with Eurolabs experts enables manufacturers to refine their product design, incorporating edge-smoothing techniques that enhance safety without compromising functionality.

Benefits for Businesses

Eurolabs laboratory service provides numerous benefits for businesses across various industries

Cost Savings By identifying and addressing potential issues early on, manufacturers can avoid costly recalls, repairs, or litigation.

Time Efficiency Our expert analysis streamlines the testing process, allowing companies to bring products to market more quickly.

Competitive Advantage Demonstrating a commitment to safety through Eurolabs laboratory service sets businesses apart from competitors and reinforces their reputation for excellence.

How Eurolabs Laboratory Service Works

At Eurolab, we understand the complexities involved in verifying edge smoothness and protection. Our experts utilize state-of-the-art equipment and rigorous testing protocols to ensure that your products meet or exceed industry standards. The process typically involves

Sampling Selecting representative samples from production batches.

Testing Conducting a series of tests, including but not limited to

Edge smoothness analysis

Material compatibility assessments

Durability and wear testing

Data Analysis Interpreting test results to determine edge smoothness and protection compliance.

QA Frequently Asked Questions about Verifying that Products Meet Safety Standards for Edge Smoothness and Protection

Q1 Why is edge smoothness and protection verification essential in consumer goods?

A1 Verifying edge smoothness and protection ensures that products meet industry standards, reducing the risk of product-related injuries.

Q2 What types of consumer goods are affected by edge smoothness and protection standards?

A2 Household items (e.g., scissors, knives), personal care products (e.g., razors), packaging materials (e.g., plastic containers), and other products with potentially hazardous edges.

Q3 How can manufacturers ensure that their products meet industry standards for edge smoothness and protection?

A3 Manufacturers can partner with Eurolab to conduct thorough testing and analysis, ensuring compliance with industry standards.

Q4 What benefits does collaboration with Eurolabs experts provide?

A4 Collaborating with our experts enables manufacturers to refine product design, enhance safety, reduce liability, and gain a competitive edge in the market.

By investing in Eurolabs laboratory service for verifying that products meet safety standards for edge smoothness and protection, businesses can safeguard their reputation, enhance consumer trust, and ensure regulatory compliance. Contact us today to learn more about how our expert analysis can benefit your organization.

Conclusion

In a competitive market where consumer satisfaction is paramount, manufacturers must prioritize product safety and quality. Eurolabs laboratory service for verifying edge smoothness and protection provides an essential tool for ensuring that products meet the required industry standards. By partnering with us, businesses can mitigate liability, enhance their brand reputation, and bring safer, more reliable products to market.

-

Testing consumer products to ensure they do not have sharp edges that could pose injury risks

-

Evaluating the safety of products by assessing potential hazards from sharp points or protrusions

-

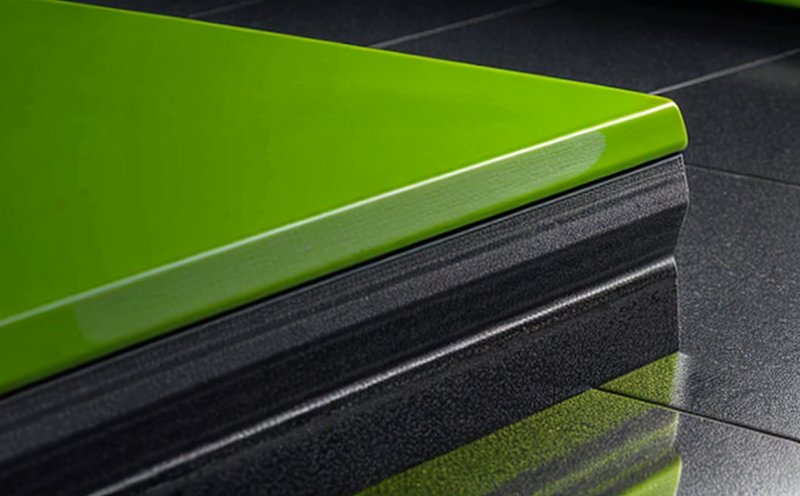

Testing the edges of materials, such as metal, glass, and plastic, for smoothness and safety

-

Simulating real-world interactions with products to determine if sharp edges could cause cuts or punctures

-

Assessing the impact of sharp edges on children's toys, tools, or household items

-

Testing the effectiveness of protective covers or shields in preventing sharp edge injuries

-

Verifying the compliance of products with safety regulations related to sharp edge risks

-

Assessing the potential for scratches, punctures, or injury from edges in electronic devices or appliances

-

Testing for sharp edges on packaging materials and their potential impact during shipping or handling

-

Evaluating the design of consumer products to eliminate unnecessary sharp points in critical areas

-

Testing items like kitchenware, furniture, and automotive components for edge safety

-

Assessing the durability of edge protection features that prevent sharp edges from emerging over time

-

Simulating everyday use to assess whether sharp edges become exposed during product wear

-

Evaluating materials used in product construction to ensure they can be safely handled without sharp edges

-

Testing for possible cuts or abrasions caused by sharp edges on clothing, textiles, or accessories

-

Testing for sharp edges in products exposed to environmental wear, such as outdoor gear or tools

-

Ensuring that products with potential sharp edges have clear warnings or safety instructions

-

Assessing the impact of sharp edges in children's products or products intended for vulnerable populations

-

Testing for the formation of sharp edges during manufacturing or due to material degradation over time

-

Verifying the effectiveness of safety measures such as rounded corners or edge buffers