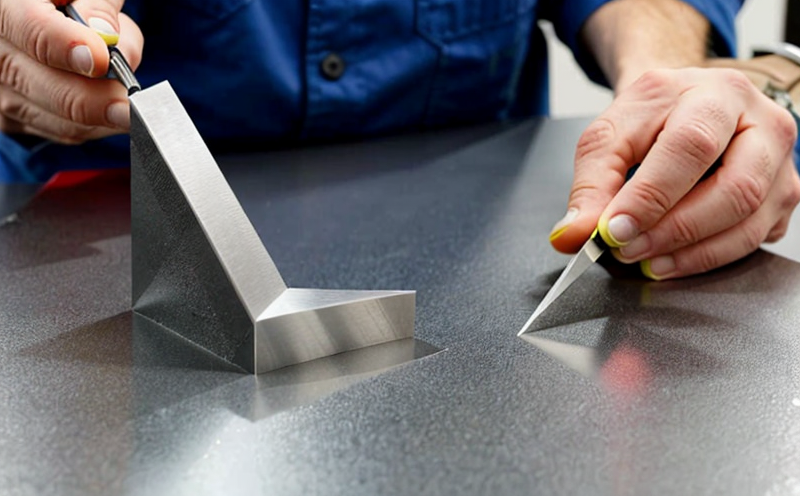

Testing for the formation of sharp edges during manufacturing or due to material degradation over time

Sharp Edges A Hidden Threat to Product Safety and Efficacy

As manufacturers strive to produce high-quality products that meet stringent industry standards, they often overlook a critical aspect of product development the formation of sharp edges during manufacturing or due to material degradation over time. Sharp edges can pose a significant risk to consumers, leading to injuries and damage to products. In this article, we will delve into the importance of testing for sharp edges, also known as edge detection or sharp edge assessment, and why it is an essential service offered by Eurolab.

What is Testing for Sharp Edges?

Testing for sharp edges involves a thorough examination of products to identify any potential hazards caused by sharp edges. This laboratory service evaluates the products design and material properties to determine if they meet industry safety standards. Our team of experts at Eurolab utilizes state-of-the-art equipment and techniques to detect even the slightest edge imperfections, ensuring that your products are safe for use.

Why is Testing for Sharp Edges Essential?

In todays competitive marketplace, manufacturers must prioritize product safety and efficacy to maintain customer trust and loyalty. Sharp edges can lead to serious injuries, damage to products, and costly recalls. By incorporating sharp edge testing into your quality control process, you can

Reduce the risk of product liability Avoid financial losses and reputational damage associated with product-related injuries or accidents.

Ensure compliance with industry regulations Meet safety standards set by regulatory bodies, such as ISO 13849-1 and EN 13451-

Improve customer satisfaction Provide consumers with confidence in your products safety, leading to increased loyalty and brand advocacy.

Enhance product design and development Identify areas for improvement and optimize product design to minimize the risk of sharp edges.

Advantages of Using Eurolabs Sharp Edge Testing Services

By partnering with Eurolab, you can benefit from

Rapid turnaround times Our experienced team provides timely results, ensuring that your products meet regulatory requirements without delay.

State-of-the-art equipment and techniques Leverage our advanced technology to detect even the slightest edge imperfections, giving you peace of mind about product safety.

Comprehensive testing and analysis Our experts provide detailed reports on test results, highlighting areas for improvement and recommendations for product design optimization.

Expertise in various industries Trust Eurolabs expertise in testing sharp edges across diverse sectors, including consumer goods, medical devices, and industrial equipment.

Frequently Asked Questions (FAQs)

Q What types of products require sharp edge testing?

A Our services are applicable to a wide range of products, including but not limited to consumer electronics, medical devices, machinery components, and household appliances.

Q How do I prepare my product for sharp edge testing?

A Simply send us your product samples in their final form, ensuring that they are free from any protective packaging or coatings.

Q What is the typical turnaround time for sharp edge testing results?

A Our standard turnaround time is 3-5 working days, although expedited services are available upon request.

Q Can you provide certification or documentation to support product compliance with industry regulations?

A Yes, we offer comprehensive reports and certificates of compliance, ensuring that your products meet regulatory requirements.

Conclusion

Sharp edges can pose a significant risk to consumers and damage your brand reputation. By incorporating sharp edge testing into your quality control process, you can ensure the safety and efficacy of your products while maintaining industry compliance. At Eurolab, our team of experts is dedicated to providing timely and accurate results, giving you peace of mind about product safety.

Dont wait until its too late trust Eurolab for sharp edge testing services that meet the highest standards of quality and integrity.

-

Testing consumer products to ensure they do not have sharp edges that could pose injury risks

-

Evaluating the safety of products by assessing potential hazards from sharp points or protrusions

-

Testing the edges of materials, such as metal, glass, and plastic, for smoothness and safety

-

Simulating real-world interactions with products to determine if sharp edges could cause cuts or punctures

-

Assessing the impact of sharp edges on children's toys, tools, or household items

-

Testing the effectiveness of protective covers or shields in preventing sharp edge injuries

-

Verifying the compliance of products with safety regulations related to sharp edge risks

-

Assessing the potential for scratches, punctures, or injury from edges in electronic devices or appliances

-

Testing for sharp edges on packaging materials and their potential impact during shipping or handling

-

Evaluating the design of consumer products to eliminate unnecessary sharp points in critical areas

-

Testing items like kitchenware, furniture, and automotive components for edge safety

-

Assessing the durability of edge protection features that prevent sharp edges from emerging over time

-

Simulating everyday use to assess whether sharp edges become exposed during product wear

-

Evaluating materials used in product construction to ensure they can be safely handled without sharp edges

-

Testing for possible cuts or abrasions caused by sharp edges on clothing, textiles, or accessories

-

Verifying that products meet safety standards for edge smoothness and protection in consumer goods

-

Testing for sharp edges in products exposed to environmental wear, such as outdoor gear or tools

-

Ensuring that products with potential sharp edges have clear warnings or safety instructions

-

Assessing the impact of sharp edges in children's products or products intended for vulnerable populations

-

Verifying the effectiveness of safety measures such as rounded corners or edge buffers