Evaluating the resistance of aerospace materials to ice formation and accumulation

Evaluating the Resistance of Aerospace Materials to Ice Formation and Accumulation Ensuring Aircraft Safety and Efficiency

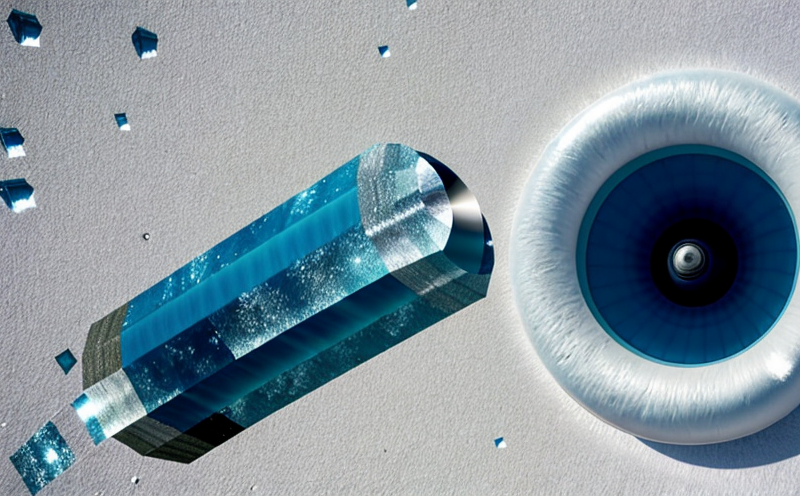

In the aerospace industry, materials play a critical role in ensuring the safety, performance, and efficiency of aircraft. Among the various environmental factors that can impact aircraft operation, ice formation and accumulation are significant concerns. Ice can lead to reduced lift, increased drag, and even catastrophic failures. To mitigate these risks, it is essential for manufacturers and operators to evaluate the resistance of aerospace materials to ice formation and accumulation.

Why Evaluate Resistance to Ice Formation and Accumulation?

The consequences of ice-related accidents can be devastating, resulting in loss of life, damage to aircraft, and significant financial losses. In addition to safety concerns, ice formation and accumulation can also impact an aircrafts performance, leading to reduced fuel efficiency, increased maintenance costs, and decreased overall productivity.

By evaluating the resistance of aerospace materials to ice formation and accumulation, manufacturers and operators can

Ensure Aircraft Safety By selecting materials that meet or exceed industry standards for ice protection, manufacturers and operators can reduce the risk of ice-related accidents.

Improve Performance Materials with high resistance to ice formation and accumulation can help maintain an aircrafts aerodynamic performance, reducing drag and increasing fuel efficiency.

Enhance Efficiency By minimizing downtime for maintenance and repair, operators can optimize their schedules and meet customer demands more effectively.

Reduce Maintenance Costs Materials that resist ice formation and accumulation require less frequent cleaning and maintenance, reducing the overall cost of ownership.

What Does Evaluating Resistance to Ice Formation and Accumulation Entail?

Our laboratory service at Eurolab provides a comprehensive evaluation of aerospace materials resistance to ice formation and accumulation. Our team uses advanced testing methods and equipment to simulate real-world conditions, providing accurate and reliable results.

We offer the following services

Ice Adhesion Testing We measure the force required to detach ice from a materials surface, simulating the forces experienced during takeoff and landing.

Ice Accumulation Testing We assess the amount of ice that accumulates on a materials surface under controlled conditions, helping to determine its resistance to ice formation.

Thermal Shock Testing We subject materials to rapid temperature changes, simulating real-world exposure to extreme temperatures.

Benefits of Evaluating Resistance to Ice Formation and Accumulation with Eurolab

By partnering with Eurolab, manufacturers and operators can

Meet Industry Standards Our laboratory is equipped to meet or exceed industry standards for ice protection, ensuring compliance with regulatory requirements.

Reduce Testing Time and Costs Our efficient testing process minimizes downtime and reduces the overall cost of evaluation.

Access Expert Analysis Our experienced team provides in-depth analysis and recommendations for material selection and design optimization.

Frequently Asked Questions

What types of materials can be evaluated?

We evaluate a wide range of aerospace materials, including aluminum alloys, titanium alloys, composite materials, and more.

How long does the testing process take?

Testing times vary depending on the specific test methods used; however, our efficient process typically takes between 1-5 days to complete.

Can I witness the testing process?

Yes, we offer witness testing for clients who wish to observe the evaluation process firsthand.

What are the benefits of evaluating resistance to ice formation and accumulation at a laboratory rather than in-flight?

Laboratory testing allows for controlled conditions, precise data collection, and reduced risk of damage or injury.

Conclusion

In conclusion, evaluating the resistance of aerospace materials to ice formation and accumulation is crucial for ensuring aircraft safety, performance, and efficiency. By partnering with Eurolab, manufacturers and operators can access advanced laboratory services, expert analysis, and comprehensive testing solutions. Our team at Eurolab is committed to providing high-quality results that meet or exceed industry standards.

Whether youre a manufacturer looking to select materials that meet regulatory requirements or an operator seeking to optimize your aircrafts performance, we invite you to experience the benefits of working with Eurolab. Contact us today to learn more about our laboratory services and how we can support your business needs.