Testing the impact of icy conditions on aerospace materials used in satellite systems

The Crucial Role of Eurolabs Icy Condition Testing Services in Ensuring the Reliability of Satellite Systems

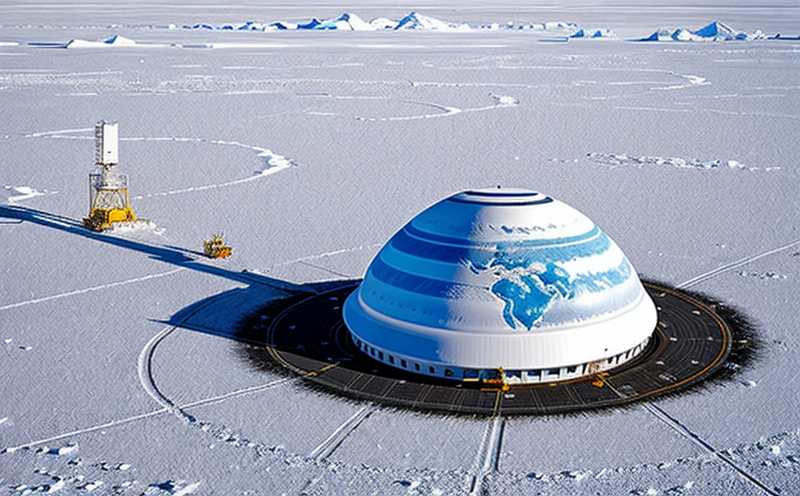

In todays era of space exploration and satellite technology, the reliability and durability of materials used in these systems are crucial for their safe operation. One of the most significant challenges faced by satellite manufacturers is understanding how their materials will perform under extreme environmental conditions, such as icy temperatures. This is where Eurolab comes in - our laboratory services provide a comprehensive testing solution to evaluate the impact of icy conditions on aerospace materials used in satellite systems.

What is Testing the Impact of Icy Conditions on Aerospace Materials Used in Satellite Systems?

Testing the impact of icy conditions on aerospace materials used in satellite systems involves subjecting materials to extreme cold temperatures, typically below -50C, to simulate real-world operating conditions. This process helps engineers and manufacturers understand how their materials will perform under such conditions, including their strength, ductility, and resistance to cracking or shattering.

Why is it Essential for Businesses?

In the aerospace industry, reliability and durability are paramount. Satellites operate in extreme environments, exposed to harsh temperatures, radiation, and other factors that can compromise their performance. If materials used in satellite systems fail to withstand these conditions, they can lead to catastrophic failures, resulting in significant financial losses, reputational damage, and even loss of life.

By testing the impact of icy conditions on aerospace materials used in satellite systems, businesses can

Ensure material reliability Understand how materials will perform under extreme environmental conditions, reducing the risk of catastrophic failures.

Improve product lifespan Extend the operational lifespan of satellites by selecting materials that can withstand harsh conditions.

Minimize maintenance costs Reduce maintenance and repair costs by identifying potential issues early on.

Enhance safety Protect personnel and assets from potential risks associated with satellite system failures.

Key Benefits of Eurolabs Icy Condition Testing Services

Our laboratory services offer a range of benefits to businesses, including

Comprehensive testing protocols Our experienced team develops customized testing protocols tailored to meet specific material requirements.

State-of-the-art equipment We utilize cutting-edge equipment and technology to simulate real-world conditions and provide accurate test results.

Expert analysis and reporting Our team provides detailed reports and recommendations for improving material performance under icy conditions.

Fast turnaround times We ensure timely delivery of results, enabling businesses to make informed decisions quickly.

Customized solutions We work closely with clients to develop testing protocols that meet specific industry standards and requirements.

QA Frequently Asked Questions

Q What types of materials can be tested using Eurolabs services?

A Our laboratory services are suitable for a wide range of materials used in satellite systems, including metals, polymers, composites, and ceramics.

Q How long does the testing process typically take?

A The duration of the testing process varies depending on the material type and testing requirements. Typically, results can be obtained within 2-4 weeks.

Q What are the typical temperatures used for icy condition testing?

A We simulate real-world conditions by subjecting materials to extreme cold temperatures, typically between -50C to -200C.

Q Can Eurolab provide customized testing protocols?

A Yes, our team develops customized testing protocols tailored to meet specific material requirements and industry standards.

Q Do you offer any post-testing services or analysis?

A Yes, we provide detailed reports and recommendations for improving material performance under icy conditions. Our team is available to discuss results and answer any questions.

Conclusion

Testing the impact of icy conditions on aerospace materials used in satellite systems is a critical step in ensuring the reliability and durability of these systems. Eurolabs laboratory services provide a comprehensive solution for businesses seeking to understand how their materials will perform under extreme environmental conditions. By leveraging our expertise and cutting-edge equipment, you can ensure that your satellite systems operate safely and efficiently, reducing the risk of catastrophic failures and minimizing maintenance costs.

Dont compromise on material reliability - trust Eurolabs icy condition testing services to give you peace of mind in an ever-evolving aerospace industry. Contact us today to learn more about our laboratory services and how we can help you meet your satellite system requirements.