Ice resistance testing for critical aerospace components exposed to low temperatures

The Crucial Role of Ice Resistance Testing for Critical Aerospace Components Exposed to Low Temperatures A Laboratory Service Provided by Eurolab

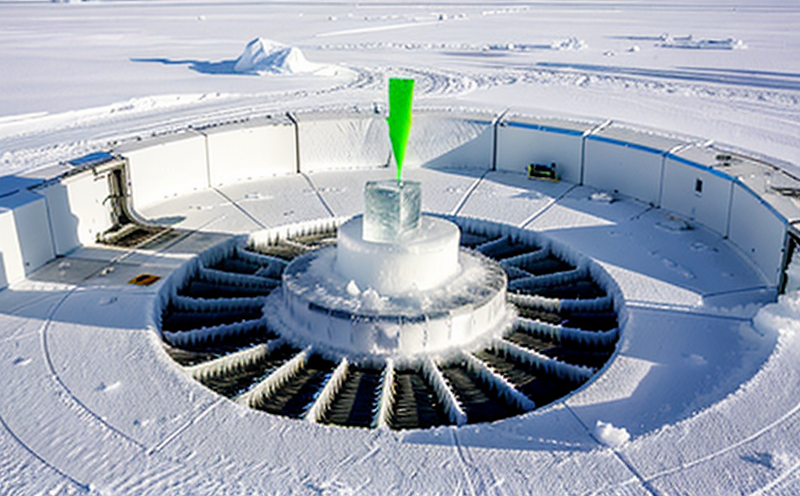

In the realm of aerospace engineering, the development and testing of critical components is a multifaceted process that requires meticulous attention to detail. One aspect that often receives less attention but is no less crucial is the ability of these components to withstand extreme temperatures, including those found in icing conditions. For this reason, ice resistance testing for critical aerospace components exposed to low temperatures has become an essential component of the development and validation process.

At Eurolab, our team of experts offers comprehensive ice resistance testing services tailored specifically for the aerospace industry. This laboratory service is designed to simulate real-world icing conditions, ensuring that your critical components can perform optimally even in the most extreme environments. In this article, well delve into the importance of ice resistance testing, highlight its advantages, and explore some frequently asked questions.

The Importance of Ice Resistance Testing for Critical Aerospace Components Exposed to Low Temperatures

Critical aerospace components are often exposed to a wide range of environmental conditions during their operational lifetime, including extreme temperatures. In these situations, ice formation can be a significant threat to the integrity and functionality of your components. Ice resistance testing is critical because it helps ensure that your components can withstand these conditions without compromising performance or safety.

Advantages of Using Eurolabs Ice Resistance Testing Services

Eurolab offers cutting-edge technology and expert analysis to provide you with accurate, reliable results for ice resistance testing. Here are some key benefits of using our services

Improved Performance By ensuring your components can withstand icing conditions, we help you maintain optimal performance levels, even in the most extreme environments.

Enhanced Safety Our testing services identify potential weaknesses, reducing the risk of component failure and ensuring passenger safety on board aircraft.

Compliance with Regulations We provide results that are compliant with industry standards and regulations, including those set by governing bodies such as the Federal Aviation Administration (FAA) and the European Aviation Safety Agency (EASA).

Reduced Maintenance Costs By identifying potential issues early in the development process, we help you avoid costly maintenance repairs down the line.

Increased Efficiency Our expert team works closely with your engineers to provide detailed insights into component performance, streamlining the development and validation process.

QA Ice Resistance Testing for Critical Aerospace Components Exposed to Low Temperatures

Here are some frequently asked questions about ice resistance testing, answered by our experts at Eurolab

What is ice resistance testing?

Ice resistance testing simulates real-world icing conditions to evaluate the performance of critical aerospace components in low-temperature environments.

Why is ice resistance testing necessary for aerospace applications?

It ensures that your components can withstand extreme temperatures and maintain optimal performance levels, thereby ensuring passenger safety on board aircraft.

What types of components are typically tested for ice resistance?

Components such as wings, control surfaces, engines, and other critical systems often require ice resistance testing.

How is ice resistance testing performed at Eurolab?

We use state-of-the-art equipment to simulate realistic icing conditions, and our expert team analyzes the results using proprietary software.

What are the benefits of working with Eurolab for ice resistance testing?

Our services offer improved performance, enhanced safety, compliance with regulations, reduced maintenance costs, and increased efficiency.

In conclusion, ice resistance testing is a critical component of the aerospace development process that ensures critical components can perform optimally in icing conditions. At Eurolab, our team of experts provides cutting-edge technology and expert analysis to provide you with accurate results. Whether your project requires compliance with industry standards or simply a safe and reliable solution, we invite you to learn more about how Eurolabs ice resistance testing services can benefit your business.

Contact us today for more information on our laboratory service provided by Eurolab.