Evaluating the strength of heat and adhesive seals in medical device packaging

Evaluating the Strength of Heat and Adhesive Seals in Medical Device Packaging Ensuring Quality and Safety

In todays highly regulated medical device industry, ensuring the quality and safety of packaging is crucial to prevent contamination, spoilage, and even harm to patients. One critical aspect of packaging evaluation is testing the strength of heat and adhesive seals used in medical device packaging. At Eurolab, our laboratory services provide a comprehensive solution for evaluating the integrity of these critical components.

The Importance of Evaluating Heat and Adhesive Seals

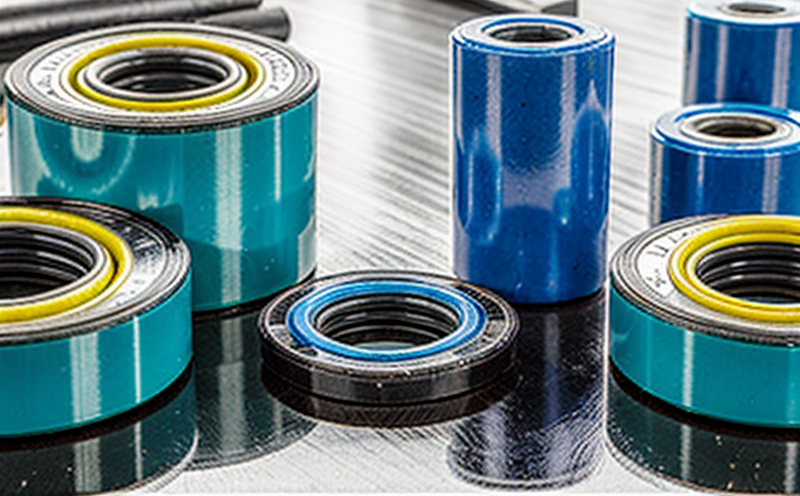

Heat and adhesive seals are essential components of medical device packaging, serving as barriers to prevent contamination, moisture ingress, and tampering. These seals can be found in various types of packaging, including trays, pouches, and blister packs. The failure of these seals can lead to compromised product integrity, recalls, and even patient harm.

Why Choose Eurolab for Evaluating Heat and Adhesive Seals?

Eurolab offers a specialized laboratory service designed to evaluate the strength and performance of heat and adhesive seals in medical device packaging. Our expert team employs advanced testing methods to simulate real-world conditions and assess the integrity of these critical components.

Advantages of Using Eurolabs Laboratory Services

Our evaluation services provide numerous benefits for businesses, including

Compliance with Regulatory Requirements Ensure that your products meet regulatory standards and requirements, reducing the risk of recalls and reputational damage.

Improved Product Safety Identify potential weaknesses in heat and adhesive seals, enabling you to correct issues before they affect patients or consumers.

Enhanced Quality Control Implement a robust quality control process by testing the strength and performance of critical packaging components.

Reduced Costs Avoid costly product recalls, rework, and waste by identifying and addressing seal integrity issues early on.

Increased Confidence in Your Products Gain peace of mind knowing that your products are packaged with reliable seals that meet or exceed industry standards.

Benefits of Evaluating Heat and Adhesive Seals

The evaluation process provides numerous benefits, including

Early Detection of Seal Weaknesses Identify potential seal weaknesses before they compromise product integrity.

Assessment of Seal Performance under Real-World Conditions Simulate actual use conditions to assess the durability and effectiveness of heat and adhesive seals.

Customized Testing Programs Tailor testing programs to your specific product requirements, ensuring accurate results and relevant data.

Expert Analysis and Reporting Receive detailed reports from our expert analysts, providing actionable insights for process improvements.

Types of Heat and Adhesive Seals Evaluated

Our laboratory services evaluate a wide range of heat and adhesive seals used in medical device packaging, including

Heat-Seal Lidding Evaluate the integrity of heat-seal lidding materials, ensuring consistent sealing performance.

Adhesive-Coated Foil Assess the strength and adhesion properties of adhesive-coated foils, critical for maintaining product sterility.

Tape Seals Test the durability and effectiveness of tape seals used in various packaging applications.

QA Section

Q What is the purpose of evaluating heat and adhesive seals?

A Evaluating heat and adhesive seals ensures that medical device packaging meets regulatory requirements, prevents contamination, and maintains product integrity.

Q How does Eurolabs laboratory service differ from others?

A Our expert team employs advanced testing methods to simulate real-world conditions, providing accurate results and actionable insights for process improvements.

Q Can I customize the testing program to suit my specific needs?

A Yes, our customized testing programs ensure that your products are evaluated under relevant conditions, providing accurate data for informed decision-making.

Q What types of packaging components can be tested?

A We evaluate a wide range of heat and adhesive seals used in medical device packaging, including lidding materials, adhesive-coated foils, tape seals, and more.

Conclusion

In conclusion, evaluating the strength of heat and adhesive seals in medical device packaging is a critical aspect of ensuring quality and safety. At Eurolab, our laboratory services provide a comprehensive solution for businesses seeking to comply with regulatory requirements, improve product safety, and reduce costs. By choosing our expert team, you can gain peace of mind knowing that your products are packaged with reliable seals that meet or exceed industry standards.

By selecting Eurolabs laboratory services, youll benefit from

Expert analysis and reporting

Customized testing programs

Early detection of seal weaknesses

Assessment of seal performance under real-world conditions

Dont compromise on product safety and quality. Choose Eurolab for evaluating the strength of heat and adhesive seals in medical device packaging. Contact us today to learn more about our laboratory services and how we can help you meet your regulatory requirements and improve product safety.