Seal strength evaluation for medical devices used in high-pressure applications

The Critical Importance of Seal Strength Evaluation for Medical Devices Used in High-Pressure Applications

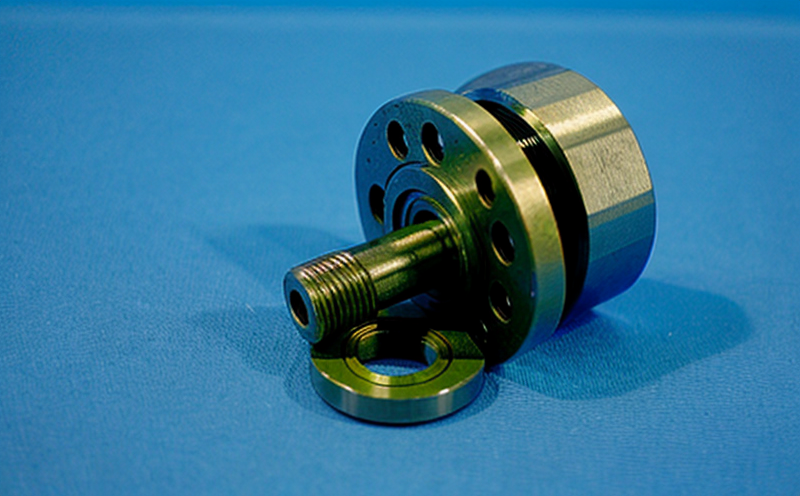

In the medical device industry, ensuring the reliability and performance of critical components is paramount. One such component is seals, which are used to prevent the leakage of fluids under high pressure in devices such as ventilators, insulin pumps, and dialysis machines. The integrity of these seals can have a direct impact on patient safety and the overall effectiveness of the device. This is where Seal strength evaluation for medical devices used in high-pressure applications comes into play.

What is Seal Strength Evaluation?

Seal strength evaluation is a laboratory service that assesses the ability of seals to withstand pressure, temperature fluctuations, and other environmental factors without compromising their integrity. At Eurolab, our experienced team of engineers and technicians utilize state-of-the-art equipment to subject seals to rigorous testing protocols, simulating real-world conditions to determine their performance under various scenarios.

Why is Seal Strength Evaluation Essential for Businesses?

In todays highly competitive medical device market, manufacturers must ensure that their products meet the stringent regulatory requirements set by organizations such as the FDA (US Food and Drug Administration) and the EU MDR (Medical Device Regulation). One of the key factors considered during the approval process is the performance of critical components like seals. Failure to meet these requirements can result in costly recalls, damage to a companys reputation, and even loss of market share.

Benefits of Using Seal Strength Evaluation for Medical Devices Used in High-Pressure Applications

Improved Product Reliability By subjecting seals to rigorous testing protocols, manufacturers can identify potential weaknesses and make necessary design improvements, leading to more reliable products.

Reduced Risk of Failure Seal strength evaluation helps prevent costly recalls and damage to a companys reputation by ensuring that critical components meet regulatory requirements.

Enhanced Patient Safety By verifying the performance of seals under various conditions, manufacturers can ensure that their devices function as intended, minimizing the risk of adverse events.

Increased Market Share Companies that prioritize seal strength evaluation demonstrate their commitment to quality and safety, which can lead to increased market share and customer loyalty.

Key Benefits of Eurolabs Seal Strength Evaluation Service

Comprehensive Testing Protocols Our experienced engineers and technicians utilize state-of-the-art equipment to subject seals to rigorous testing protocols, simulating real-world conditions.

Customized Solutions We work closely with our clients to develop tailored testing plans that meet their specific needs and regulatory requirements.

Timely Results Our efficient testing processes ensure that results are delivered promptly, minimizing delays in product development and approval.

Frequently Asked Questions

Q What types of medical devices require seal strength evaluation?

A Devices that operate under high pressure, such as ventilators, insulin pumps, and dialysis machines, typically require seal strength evaluation to ensure their reliability and performance.

Q How do I determine if my product requires seal strength evaluation?

A Manufacturers should consult regulatory requirements set by organizations like the FDA and EU MDR to determine whether seal strength evaluation is necessary for their products.

Q Can Eurolab provide customized testing plans for my specific needs?

A Yes, our experienced engineers and technicians work closely with clients to develop tailored testing plans that meet their unique requirements.

Conclusion

In conclusion, Seal strength evaluation for medical devices used in high-pressure applications is a critical service that ensures the reliability and performance of critical components. At Eurolab, we offer comprehensive testing protocols, customized solutions, and timely results to support manufacturers in meeting regulatory requirements and ensuring patient safety. By prioritizing seal strength evaluation, companies can improve product reliability, reduce risk of failure, enhance patient safety, and increase market share.