Seal strength evaluation for packaging used in sterile medical devices

The Crucial Role of Seal Strength Evaluation in Packaging Sterile Medical Devices Why Your Business Needs It

In the highly regulated world of medical device packaging, ensuring the integrity and safety of products is paramount. One critical aspect that often goes unnoticed is the seal strength evaluation for packaging used in sterile medical devices. As a leading laboratory service provider, Eurolab offers this essential testing solution to help businesses ensure their packaging meets the stringent requirements of regulatory bodies and industry standards.

What is Seal Strength Evaluation?

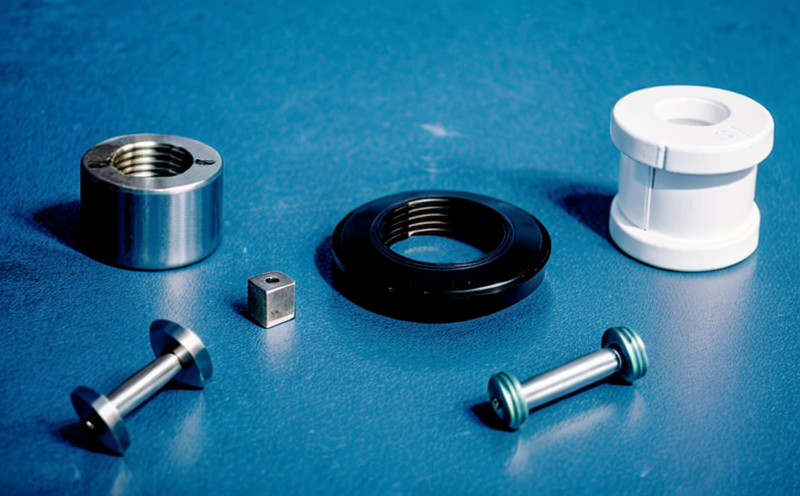

Seal strength evaluation refers to the assessment of the sealing capabilities of packaging materials used in medical device packaging. This critical analysis determines whether the seals can maintain a tight closure, prevent moisture ingress, and withstand various environmental conditions without compromising the sterility of the products within. The primary objective of seal strength evaluation is to guarantee that the packaging protects the sterile medical devices from contamination, ensuring patient safety.

Why Seal Strength Evaluation Matters

In the medical device industry, the stakes are high. Packaging failures can lead to product recalls, damage to brand reputation, and most importantly, harm to patients. Regulatory bodies such as the US FDA and European regulatory agencies impose strict guidelines for packaging materials used in medical devices. Failure to comply with these regulations can result in significant financial penalties and loss of business.

The advantages of seal strength evaluation are numerous, and Eurolabs comprehensive laboratory service offers several key benefits

Advantages of Seal Strength Evaluation

Compliance with Regulatory Requirements Ensure your packaging meets the stringent standards set by regulatory bodies, reducing the risk of product recalls and reputational damage.

Guaranteed Product Safety Verify that your sterile medical devices are protected from contamination, ensuring patient safety and minimizing liability risks.

Cost Savings Identify and address packaging-related issues before products reach the market, avoiding costly rework or recalls.

Improved Brand Reputation Demonstrate a commitment to quality and safety by adhering to industry standards and regulatory requirements.

Additional Benefits

Reduced Risk of Product Contamination Seal strength evaluation ensures that your packaging maintains its integrity in various environmental conditions, preventing product contamination.

Increased Efficiency Eurolabs streamlined laboratory service minimizes testing time, enabling you to bring products to market more quickly.

Expert Support Our experienced team provides expert guidance and support throughout the testing process.

How Seal Strength Evaluation Works

Eurolabs seal strength evaluation involves a comprehensive assessment of packaging samples using advanced testing methods. This includes

Sample Preparation Samples are carefully prepared for testing, ensuring accurate results.

Testing Methods Advanced techniques such as tensile testing, peel testing, and seal burst testing are employed to evaluate the sealing capabilities of packaging materials.

Data Analysis Results are meticulously analyzed, providing detailed insights into packaging performance.

QA Frequently Asked Questions about Seal Strength Evaluation

Q What types of medical devices require seal strength evaluation?

A All sterile medical devices, including injectables, implants, and wound care products, require seal strength evaluation to ensure packaging integrity.

Q How often should seal strength evaluation be performed?

A Regular testing is recommended to maintain compliance with regulatory requirements and industry standards. Frequency of testing may vary depending on product type, material changes, or significant changes in manufacturing processes.

Q Can Eurolabs laboratory service accommodate my specific testing needs?

A Yes, our experienced team provides customized testing solutions tailored to your specific needs, ensuring seamless integration into your quality control protocols.

Conclusion

In the highly competitive world of medical device packaging, seal strength evaluation is a critical component of ensuring product safety and regulatory compliance. Eurolabs comprehensive laboratory service offers expert support, reducing the risk of packaging-related issues and minimizing liability risks. By partnering with Eurolab, you can ensure that your sterile medical devices meet the highest standards of quality and safety.

Dont compromise on patient safety or your business reputation trust Eurolab for seal strength evaluation services that guarantee compliance, cost savings, and improved brand reputation.