Finite element elasticity modeling

Unlocking Efficiency How Finite Element Elasticity Modeling Can Transform Your Business

In todays fast-paced and competitive business landscape, companies are constantly seeking innovative ways to optimize their products, processes, and performance. One powerful tool that can help achieve these goals is finite element elasticity modeling. This cutting-edge laboratory service has revolutionized the way businesses approach material science and structural analysis.

At Eurolab, our team of experts provides top-notch finite element elasticity modeling services to industries worldwide. By leveraging advanced computational tools and methodologies, we empower companies to make informed decisions, reduce costs, and enhance product quality. In this article, well delve into the world of finite element elasticity modeling, exploring its benefits, applications, and how it can transform your business.

What is Finite Element Elasticity Modeling?

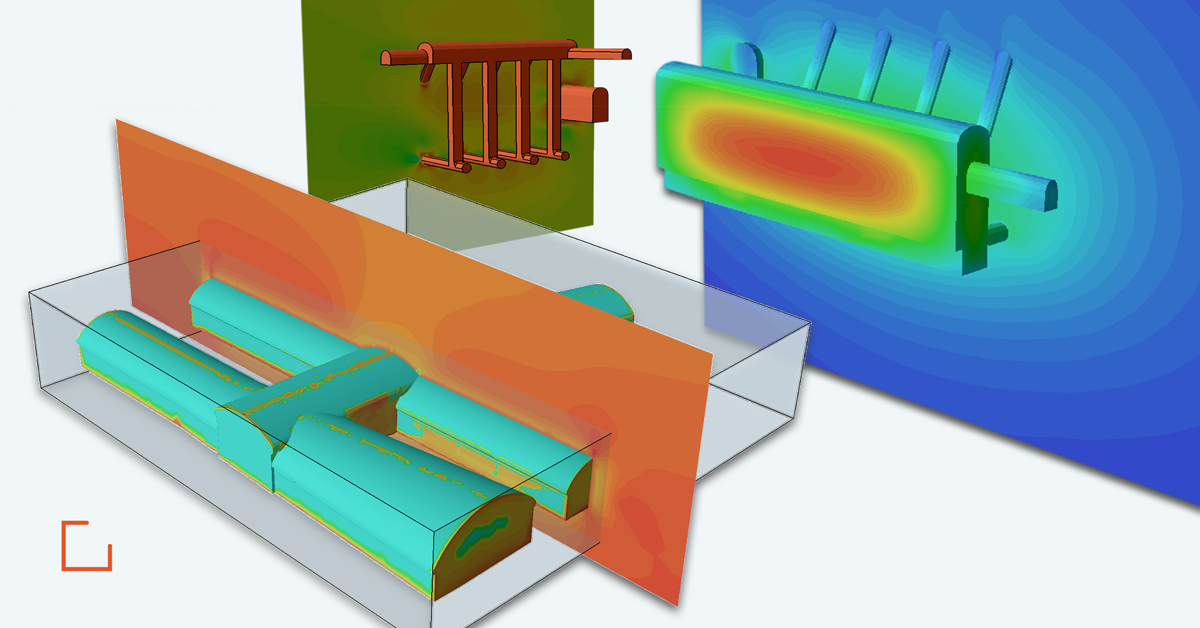

Finite element elasticity modeling is a numerical method used to analyze the behavior of materials and structures under various loads. It involves dividing complex systems into simpler, manageable elements, which are then analyzed using sophisticated computational algorithms. This approach enables scientists and engineers to simulate real-world scenarios, predict material response, and optimize designs without the need for physical prototypes.

Finite element elasticity modeling is a crucial tool in product development, ensuring that materials can withstand extreme conditions, such as temperature fluctuations, mechanical stresses, and chemical exposure. By simulating these scenarios, companies can identify potential weaknesses, improve material properties, and reduce the risk of costly failures.

The Advantages of Finite Element Elasticity Modeling

Our finite element elasticity modeling services offer a multitude of benefits for businesses across various industries. Here are just some of the key advantages

Reduced Development Time and Costs

Finite element elasticity modeling accelerates product development by allowing companies to simulate and test designs virtually. This reduces the need for physical prototypes, saving time, money, and resources.

Faster Design Cycles With finite element elasticity modeling, design cycles are significantly shortened, enabling businesses to respond quickly to market demands.

Cost Savings By eliminating the need for extensive prototype testing, companies can save millions of dollars in development costs.

Improved Material Properties

Our finite element elasticity modeling services help companies optimize material properties, ensuring that products meet or exceed performance requirements.

Enhanced Strength and Durability Simulated material behavior helps businesses design stronger, more durable materials.

Increased Efficiency Finite element elasticity modeling optimizes material usage, reducing waste and improving overall efficiency.

Risk Reduction

By simulating real-world scenarios, companies can identify potential weaknesses and mitigate risks associated with product failure.

Predictive Maintenance Finite element elasticity modeling enables businesses to anticipate maintenance needs, reducing downtime and increasing productivity.

Failure Prevention Simulated material behavior helps companies design products that withstand extreme conditions, minimizing the risk of costly failures.

Scalability and Customization

Our finite element elasticity modeling services cater to a wide range of industries and applications, from aerospace to consumer goods.

Industry-Specific Solutions Eurolabs experts provide tailored solutions for various industries, ensuring that our clients receive customized support.

Multi-Physics Capabilities Our finite element elasticity modeling tools account for multiple physical phenomena, such as temperature, stress, and fluid dynamics.

QA Frequently Asked Questions about Finite Element Elasticity Modeling

Weve addressed some of the most common questions about finite element elasticity modeling below

Q1 What is the primary benefit of finite element elasticity modeling?

The primary benefit of finite element elasticity modeling is its ability to simulate real-world scenarios, allowing businesses to make informed decisions and optimize product performance.

Q2 Can finite element elasticity modeling be applied to various industries?

Yes, our services cater to a wide range of industries, including aerospace, automotive, consumer goods, and more. Our experts provide tailored solutions for each industry, ensuring that clients receive customized support.

Q3 How long does the finite element elasticity modeling process typically take?

The duration of our services varies depending on project complexity and client needs. However, we strive to deliver high-quality results within a reasonable timeframe, often exceeding client expectations.

Q4 What software or tools do you use for finite element elasticity modeling?

We employ cutting-edge computational tools and methodologies, including Software/Tool Name, which enables us to simulate complex systems with accuracy and precision.

Q5 Can I learn more about your teams expertise in finite element elasticity modeling?

Yes, our team of experts has extensive experience in finite element elasticity modeling. Weve worked with clients worldwide, providing tailored solutions for various industries and applications.

Conclusion

Finite element elasticity modeling is a powerful tool that can transform the way businesses approach material science and structural analysis. By leveraging advanced computational tools and methodologies, Eurolabs services help companies optimize product performance, reduce development time and costs, and mitigate risks associated with product failure.

Whether youre a seasoned engineer or an industry newcomer, our team of experts is committed to delivering top-notch finite element elasticity modeling services that meet your unique needs. Dont let material uncertainty hold you back unlock the full potential of your products with Eurolabs cutting-edge expertise.

About Eurolab

At Eurolab, we pride ourselves on providing high-quality laboratory services that exceed client expectations. Our team of experts is dedicated to delivering top-notch finite element elasticity modeling solutions for industries worldwide. Were committed to pushing the boundaries of material science and structural analysis, empowering businesses to innovate and succeed in a rapidly evolving market.

Let us help you unlock efficiency, optimize product performance, and achieve your business goals. Contact Eurolab today to learn more about our finite element elasticity modeling services and how they can transform your organization.