Material stiffness testing

The Crucial Role of Material Stiffness Testing in Ensuring Product Reliability

In todays fast-paced manufacturing landscape, businesses are constantly seeking innovative ways to improve product performance, efficiency, and safety. One critical aspect that often goes unnoticed is the importance of material stiffness testing. This laboratory service, offered by Eurolab, provides manufacturers with a comprehensive understanding of their materials mechanical properties, enabling them to make informed decisions that impact the entire production process.

Material stiffness testing, also known as flexural stiffness or bending stiffness, measures the resistance of a material to deformation under load. Its an essential parameter in determining the structural integrity and durability of various products, including building materials, aerospace components, automotive parts, and medical devices. By evaluating the stiffness of materials, manufacturers can predict their performance under various environmental conditions, reducing the risk of product failure and ensuring customer satisfaction.

Advantages of Material Stiffness Testing

The benefits of material stiffness testing are numerous and far-reaching. Here are some key advantages that make it an indispensable service for businesses

Improved Product Design By understanding the mechanical properties of materials, designers can optimize product dimensions, reduce weight, and enhance performance.

Enhanced Safety Material stiffness testing helps identify potential weaknesses in products, minimizing the risk of accidents, injuries, or fatalities.

Increased Efficiency Accurate material selection and processing lead to reduced production costs, increased productivity, and faster time-to-market.

Compliance with Regulations Many industries require compliance with specific standards and regulations. Material stiffness testing ensures that products meet these requirements, reducing the likelihood of costly recalls or legal issues.

Reduced Warranty Claims By identifying potential material-related issues upfront, manufacturers can minimize warranty claims and associated costs.

Why Choose Eurolab for Material Stiffness Testing?

When it comes to material stiffness testing, precision, accuracy, and expertise are paramount. At Eurolab, we offer

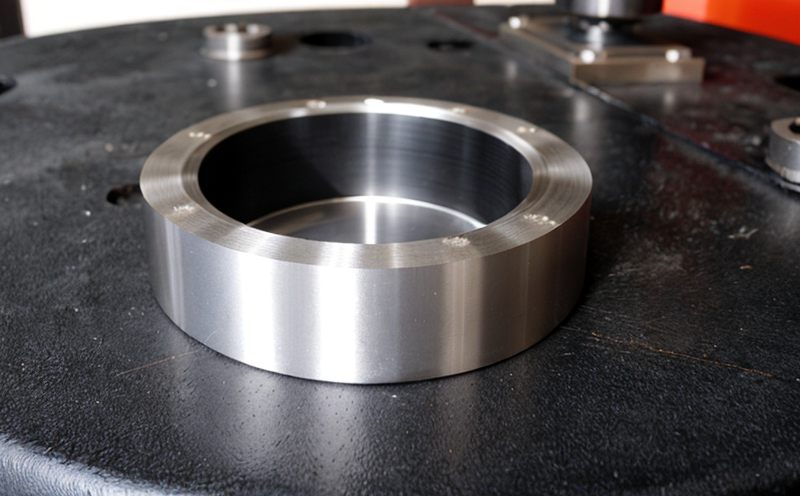

State-of-the-Art Equipment Our laboratory is equipped with the latest testing machines and software, ensuring accurate and reliable results.

Experienced Professionals Our team of skilled technicians and engineers has extensive knowledge in material science and testing procedures.

Customized Solutions We provide tailored services to meet specific client needs, including sample preparation, testing protocols, and data analysis.

How Does Material Stiffness Testing Work?

The process is straightforward

Sample Preparation Eurolab receives the materials or products for testing in their original form or as specified by the client.

Testing Protocol Our technicians follow a standardized procedure to prepare the samples for testing, ensuring that all necessary parameters are met.

Measurement and Data Analysis The samples are subjected to load or deformation, and the resulting data is collected using specialized equipment. Our team then analyzes the results, providing detailed reports on material stiffness.

Frequently Asked Questions

Weve compiled a list of common questions and answers to address your concerns

Q What types of materials can be tested for stiffness?

A Eurolab offers testing services for various materials, including metals (e.g., steel, aluminum), plastics (e.g., polypropylene, polycarbonate), composites, ceramics, and glass.

Q How do I prepare my samples for testing?

A Our team will provide specific guidelines on sample preparation, which may involve cleaning, cutting, or machining the material to meet testing requirements.

Q What are the benefits of using a laboratory service like Eurolab?

A By outsourcing material stiffness testing to an experienced laboratory like Eurolab, manufacturers can save time and resources, while also ensuring accurate and reliable results.

Q Can you provide customized testing protocols for specific client needs?

A Yes, our team is happy to work with clients to develop tailored testing procedures that meet their unique requirements.

Conclusion

Material stiffness testing is a critical laboratory service that provides businesses with the knowledge they need to create high-performance products, enhance safety, and reduce costs. At Eurolab, we understand the importance of accurate material characterization and are committed to delivering exceptional results through our state-of-the-art equipment, experienced professionals, and customized solutions. By partnering with us, manufacturers can ensure their products meet the highest standards of quality, reliability, and durability.

Dont compromise on product performance choose Eurolab for your material stiffness testing needs today!