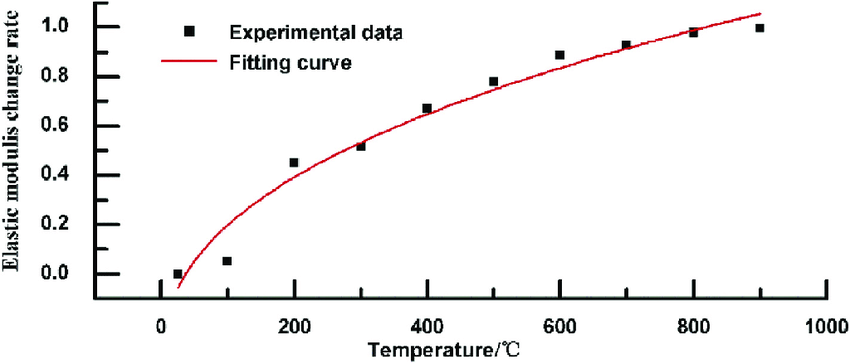

Modulus variation with temperature

The Crucial Role of Modulus Variation with Temperature in Ensuring Material Reliability

In todays fast-paced and highly competitive business landscape, manufacturers are constantly seeking ways to optimize their production processes, reduce costs, and improve the overall quality of their products. One critical factor that often gets overlooked is the measurement of modulus variation with temperature (MVT). This laboratory service, provided by Eurolab, is essential for businesses looking to ensure the reliability and performance of their materials under various operating conditions.

What is Modulus Variation with Temperature?

Modulus variation with temperature refers to the change in a materials elastic properties as it is subjected to different temperatures. In simple terms, it measures how a material responds to stress and strain at varying temperatures. This property is crucial in determining the suitability of materials for specific applications, such as automotive, aerospace, or construction.

Why is Modulus Variation with Temperature Important?

The modulus variation with temperature is essential for several reasons

Material selection By understanding how a materials modulus changes with temperature, manufacturers can select the most suitable material for their application, reducing the risk of material failure and associated costs.

Design optimization Accurate measurement of MVT enables engineers to optimize product design, ensuring that materials are used within their safe operating range, thus preventing premature wear or damage.

Quality control Regular monitoring of a materials modulus variation with temperature helps manufacturers detect any changes in material properties over time, enabling prompt corrective action to maintain quality standards.

Advantages of Using Modulus Variation with Temperature

Using MVT provides numerous benefits, including

Key Benefits

Improved product reliability By understanding how materials behave under various conditions, manufacturers can design products that are less prone to failure.

Enhanced material selection Accurate measurement of MVT enables the selection of materials that meet specific performance requirements, reducing the risk of material failure and associated costs.

Reduced testing time With access to reliable data on a materials modulus variation with temperature, manufacturers can optimize their testing processes, saving valuable time and resources.

Increased design flexibility By understanding how materials respond to different temperatures, engineers can create more innovative and efficient designs.

How Does Eurolabs Modulus Variation with Temperature Service Work?

Our team of expert technicians uses state-of-the-art equipment to measure the modulus variation with temperature of various materials. The process typically involves

Material preparation Samples are carefully prepared for testing, taking into account any specific requirements or constraints.

Testing The material is subjected to a range of temperatures, and its elastic properties are measured using specialized equipment.

Data analysis Our team analyzes the data collected during the test, providing detailed reports on the materials modulus variation with temperature.

Frequently Asked Questions (FAQs)

Q What types of materials can be tested for modulus variation with temperature?

A Eurolab offers MVT testing services for a wide range of materials, including metals, polymers, ceramics, and composites.

Q How long does the testing process typically take?

A The duration of the test depends on the specific requirements of each project. However, our team works efficiently to ensure that results are provided within a reasonable timeframe.

Q What kind of data can I expect from Eurolabs MVT service?

A Our comprehensive reports include detailed graphs and tables illustrating the materials modulus variation with temperature, allowing you to make informed decisions about your product design and material selection.

Conclusion

In conclusion, measuring modulus variation with temperature is a critical aspect of ensuring material reliability. By understanding how materials behave under various conditions, manufacturers can optimize their production processes, reduce costs, and improve the overall quality of their products. Eurolabs MVT service provides accurate and reliable data, enabling businesses to make informed decisions about material selection and product design.

By leveraging the expertise and capabilities of our team, you can ensure that your materials meet the required performance standards, reducing the risk of material failure and associated costs. Contact us today to learn more about how Eurolabs Modulus Variation with Temperature service can benefit your business.